Good news and bad news:

Good: I found the reason for the leaking gearbox on my Navigator: the bottom screws were too long and bottomed out withouth tightening the gearbox cover. Shorter screws solved the problem.

Bad News: Another seized piston! This time the left one. I was doing 60mph when the engine sounded stressed and I pulled the clutch.

There is a cylinder liner in the barrel but on the right side. No damage on this side. I had the barrels rehoned after the engine seized the first time. so there should have benn a bit more clearance.The piston size is now 63mm+ 0,10. There are no other oversized pistons available as far as I know. Except one +0.20 piston on Ebay.

Will find out what to do after I spoke the the man in the engine shop.

Navigator seized

- Log in to post comments

What clearances were you…

What clearances were you using?. Might be helpful if we could see all round the piston.

- Log in to post comments

That's really grim news…

That's really grim news after all your hard work Ulrich, so sorry to hear it - as we've discussed before Andy's advice over timing is absolutley crucial and I know you have said you had set the timing to 24 deg. However, strange it has seized on only one side which might point towards a clearance issue. Another thought - how many miles had you done since your last top end rebuild? I would be nervous about sustaining 60 mph for any length of time on a freshly rebuilt Navigator engine until I had at least 500 miles on it ……but may be that is me just being over cautious having had similar seizures in the past due to over enthusiasm and impatience as a teenager! Good luck with sourcing OE (Hepolite) oversize pistons which are difficult to find, there are modern manufacture Australian ones from JP Pistons available for about £200 a pair on ebay and elsewhere but I've seen mixed reviews. Perhaps someone can provide definitive advice based on personal experience? Nick

- Log in to post comments

1 new piston

I just completed the order of one new piston and rings form the NOC shop.I checked the timing and it is at 24° BTDC. We can use the same size piston . There are no mark in the cylinder, just aluminium sticking to it.

I was at the engine shop today and showed the damage to the owner.

He suggested more piston clearance.

We are now at about +.20 because of the rehoned cylinders after the first seizure.

Will report when the piston is here.

- Log in to post comments

Seized piston

Hi Ulrich,

Which piston seized?

It is fairly common, after high mileage, for the sludge trap in the crankshaft to become so full of sludge that the left hand big end journal oil feeds get blocked. No oil is thrown onto the cylinder liner and the piston will seize.

If the piston that seized was on the left side, and you did not clean the sludge trap in your rebuild, this MAY be the answer.

Peter

- Log in to post comments

Sludge trap

The same said our local Norton engine specialist to me. Looking forward to another engine teardown... I left the bottom end as it was because I felt no play in the big ends.

- Log in to post comments

Hello Ulrich, when you come…

Hello Ulrich, when you come to do this, I was amazed at how much hard sludge there was in the trap. I used a wire to chip it out, then pipe cleaners and parafin until there was no evidence of any sludge, I did have to take the crank out to do this though as I cleaned from the journals in. You may find your big end bearings are scored as well. Hope it wporks out for you.

- Log in to post comments

Sludge trap cleaning

Hi Ulrich,

I've done at least three different lightweight cranks. In all cases the aluminium cover screw on the end of the sludge trap refused to move with a broad screwdriver to the shallow slot. The slot is only of use to insert a new plug.

Grip the crankshaft in a large vice on the flywheel.

I drilled a 3mm hole through the centre of the plug. Then two more 3mm holes along the slot. The slot helps locate the drill. Then use a needle file to remove the bridge between the holes and insert a strong large flat bladed screwdriver. If is has a square shaft or a driving hole in the handle all the better. You may need a Mole-grip on the screwdriver shaft.

If that doesn't work, lengthen the slot until it is at the top of the threads, don't damage the threads of the crankshaft, and try again. Hopefully the cover screw will collapse inward a bit and lose it's grip on the crankshaft.

On a Jubilee, which has a smaller diameter screw cover to Nav/Electra, I had to resort to another pair of 3mm holes, like a number 5 on a dice, and make two slots, elongated to the threads. I was able to punch the four quarters of the mutilated screw inwards and to freedom.

Then I used the strong long screwdriver to chisel and remove the sludge. As Andrew says this will be compacted. Be brutal and ensure there are no pieces left inside. The sludge always collects more at the far end, the left end, where the oil flow is lowest.

If you have a parts washer, use it to thoroughly clean the oil passage from the timing side oil feed (end of crankshaft) to the sludge trap. Or an airline can be used. Bits of aluminium may have fallen in here from all the drilling and filing. A trick is to use a grease gun on the oil feed to fill the oil passage with grease before you start drilling the aluminium. Then, at the end, push in more grease to drive any swarf into the sludge trap where you can remove it. Then clean out the grease with paraffin and pipe cleaner. (or parts washer)

Clean, clean, clean.

Check your new cover screw fits. Apply a thread sealant and screw it fully home.

Norton secured the screw cover by deforming the thread after insertion.

I apologise if my responses on this forum sometimes seem a bit lengthy, but future readers may not have the experience you have.

Please don't lose your enthusiasm for the Navigator. I'd love to see you write something in Roadholder.

Best wishes

Peter

- Log in to post comments

Need more pics to confirm,…

Need more pics to confirm, but seizing on the side with nodules on the piston top suggests a 4 cornered seizure from pre-ignition heating the piston. The 4 corners are the points where the piston is thickest and the more material the more expansion ie either side of the pin on both sides.

- Log in to post comments

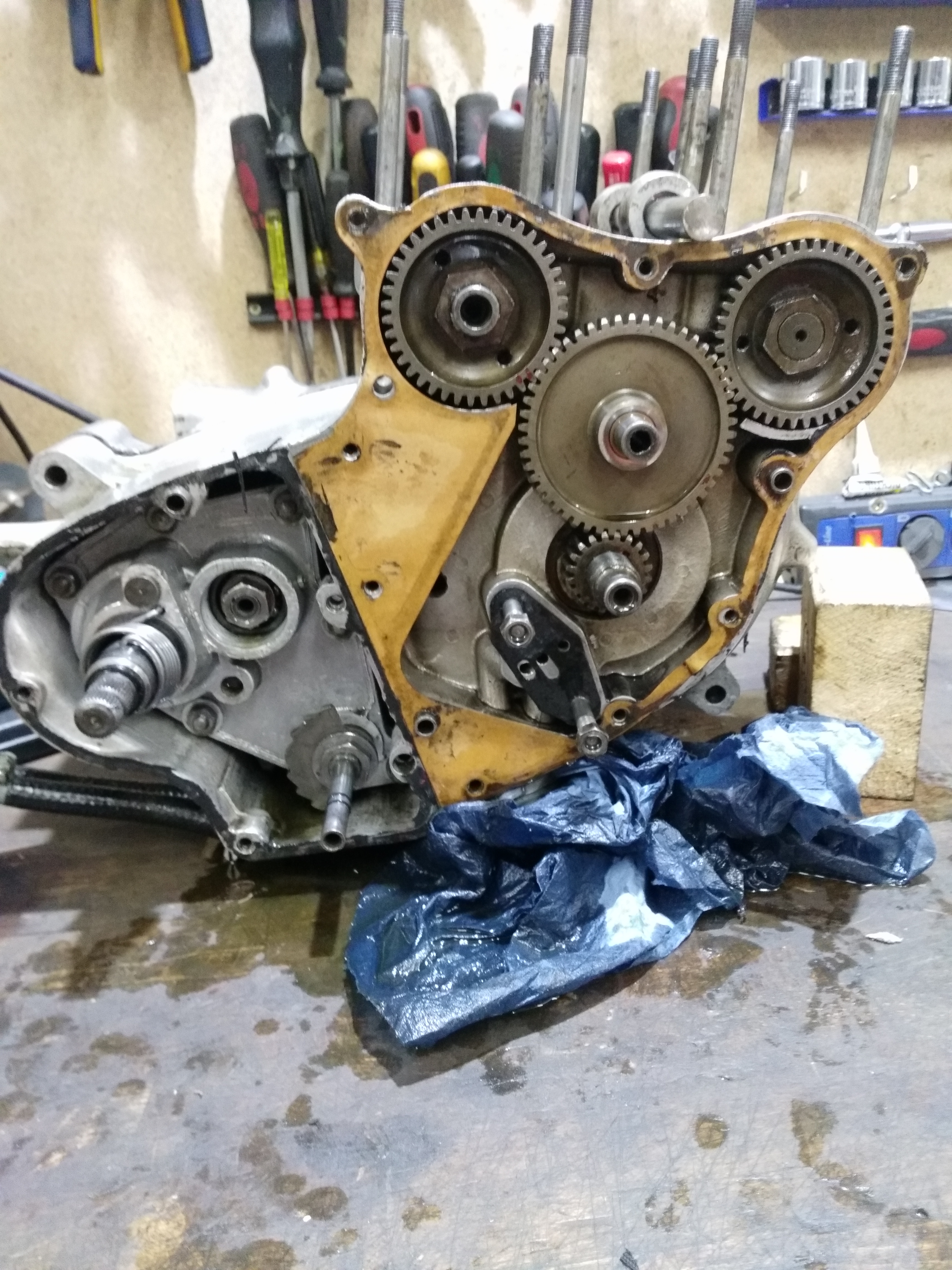

Engine is out

Today I started to pull the engine form my Navigator.

I came up to this stage. Are the nuts on the camshafts right- or left hand thread?

- Log in to post comments

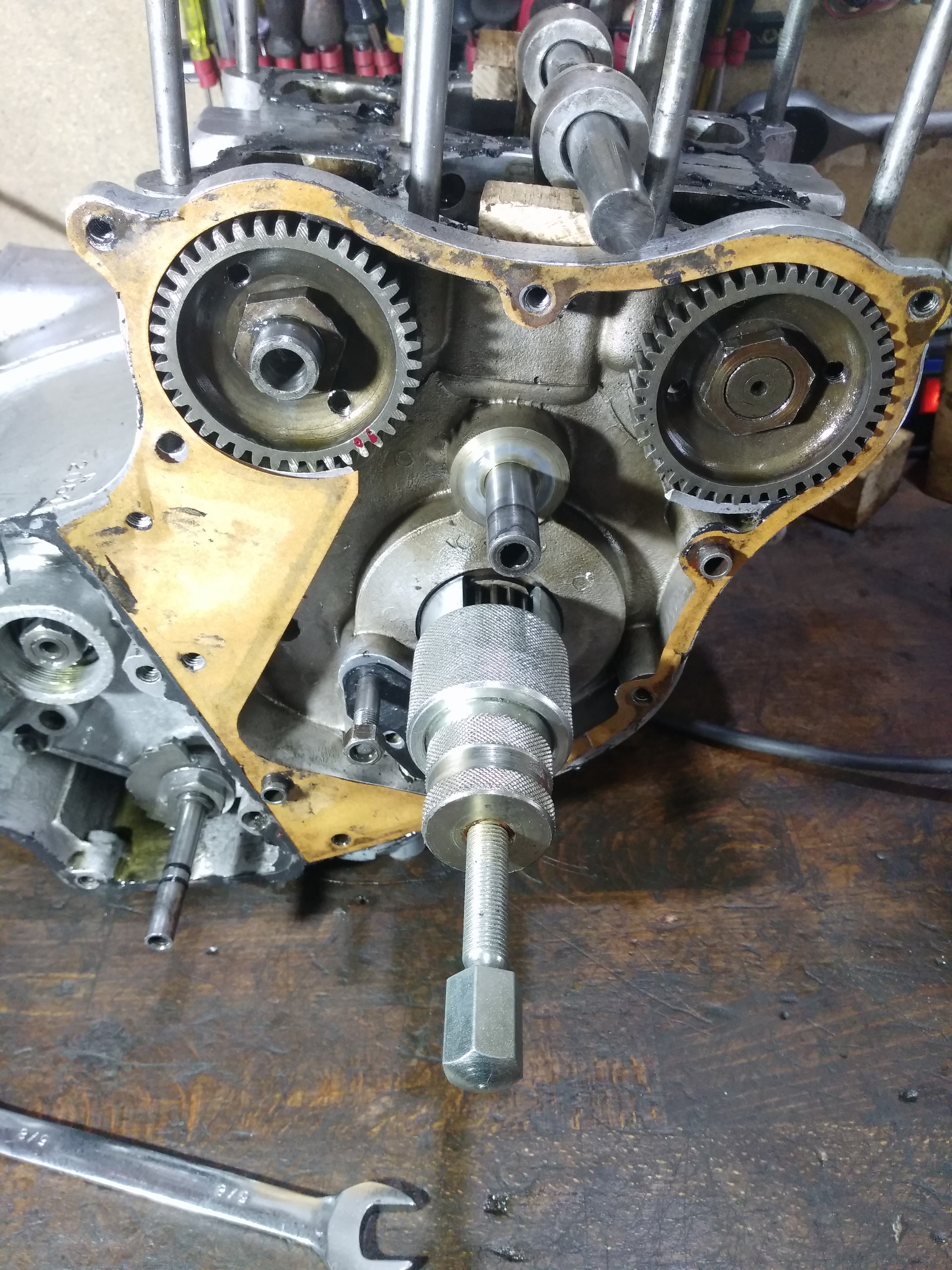

Camshaft nuts

Ulrich,

The camshaft nuts are right hand thread. If you are going to clean the sludge trap.

Remove the intermediate pinion. Slides off.

Do not remove the camshaft nuts. Not required.

Remove crankshaft pinion on timing side. Special puller is good to get into space by 3-sided washer.

Remove primary drive cases and contents.

Remove all fastenings between the crankcase halves.

Separate the crankcases and the camshafts stay captive.

Probably more controlled if you drop the gearbox internals out before splitting the crankcases.

The crankshaft can now be removed. Sometimes the timing side bearing is tight on the crankshaft. Don't damage the timing side end detail on the crankshaft by hammering. This is important for a good oil feed seal. Use a tube to push on the shoulder at the top of the left hand thread if necessary.

Looks to be going well.

Peter

- Log in to post comments

Engine in pieces

Today I borrowed the three jar puller for the crankshaft half time pinion and took the engine apart. I left the camshafts in but noticed excessive play in the timing side bushes so the had to come out also.The nuts were very tight but in the end they loosened up and I could pull the pinions.

The gearbox was taken out as a cluster. I noticed a loose clutch operator lockring and also a loose bolt for the gearbox plunger. Also the layshaft bush fell out and it also has excessive play.

In the left side engine housing I found a bolt with a small hole acting as the crankcase breather. The part NO.23367 in the NOC shop crankcase breather surely looks different !

The big ends also have too much play. The crank journals need a regrind and oversize shells. The sludge trap plug came out easily. Not much inside. I flushed it with my parts washer.

Are the bushes for the camshafts available somewhere? Also the layshaft bush? Can´t find these in the NOC shop.

So in retrospective it was good to open the engine once more find all those faults

I guess it will take longer to get the Navigator back on the road!

- Log in to post comments

Hi Ulrich - for the closed…

Hi Ulrich - for the closed type (top hat shape) layshaft bush I could only find a stock at Norvil, don’t know about the other bush though, sorry. You could try Russell Motors as well, they’ve been closed for the last 3 months but had a courtesy phone call from them (after my parts request letter sent in April) last week saying they’re due to re-open next week (I think).

Bruce

- Log in to post comments

The piston failure is not…

The piston failure is not down to a blocked crank then, So some more carefull detective work is needed. What piston/bore clearance have you been using.?., If your engineer is a car guy he may be not familliar with aircooled motors.

- Log in to post comments

oil suppliy

hello now everyone as gone thought everything they can think of that the cause of this unfortunate incident but as any of you come across the oil strainer filter in the sump plate As I have been dismantling my 350 Navigator I found the sump strainer filter to be partially blocked by red Hermerite gasket sealer on further inspection, I find a layer of thick oily gunge that was also blocking the oilways you should check this part of the sump plate is clean If the oil pump cannot pick up oil you get a seizure somewhere, yours anna j

- Log in to post comments

Oil supply

Hi Ulrich,

Trust the rebuild is going OK. Have been hoping all avenues have been covered with the comments above but one thing nags.

I have reconditioned five or six lightweight oil relief valves. Wrote an article about it for Roadholder a few years ago. RH333 Page 6 Sept 2015.

It is not like the the oil pressure relief valves in heavyweights which have a ball against a seat. Not prone to the same problem.

You should check that the Navigator pressure relief valve is working, if you did not do it at the rebuild.

Very common for particles in the oil, like carbon, to seep between the close fitting piston and bore of the relief valve. The piston jams in the bore and is not pushed back onto the seat by the spring. Oil then spills continuously from the high pressure oil supply before it gets to the crankshaft. Of the handful of pressure relief valves I inherited, the MAJORITY were in this condition. It's easy to check the valve is clean and piston free by separating the valve body halves.

No surprise that the Norton Twins workshop manual mentions the importance of checking the lightweight oil pressure relief valve in its opening pages, but how many of us do!!

And crankshaft oil seal in good order.

And conical rubber seal on oil pump.

Let us know how you are getting on.

Peter

- Log in to post comments

Engine in pieces

Thansk Peter for the hint!

The engine is totally apart right now. A friend of mine made a new oversize bush for the layshaft. The old one turned in its seating and was totally worn out.

Not pressed home on the pic!

Also a new crankcase vent tube with a bigger diameter was installed. Some PO drilled in a bolt with a 3mm hole in it. I will fit a small breather valve so that air can get out of the crankcase but not in!

The old vent hole towards the sprocket was already blocked.

Crankshaft needs regrinding to fit +0.10 shells. I am waiting for the parts from Norvil. New lightweight bearings, big end shells and a gasket then and some other thingies..

And the barrels and cyliner are ready to be installed I will pick them up when I will bring the crankshaft to the engine shop.

- Log in to post comments

Bushes

Hi Uli,

I got my camshaft and other bushes from Russel Motors. Very reasonably priced but I had to keep calling until someone took my order. I had to wait a while until he was "Going to the warehouse across town" to find out if they could supply them. Worth the wait though.

Dennis

- Log in to post comments

Navigator pistons/bore clearance

Hi Navigators: I have already posted this on the forum, but your correspondence here seems closer to the mark. My Navigator pistons are in an engineering shop, and he wants to know what the maximum and minimum gap tolerance is between the barrels and pistons. Mine are 40 thou oversize. He is concerned there may be too big a gap there

- Log in to post comments

Although Ulrich has been…

Although Ulrich has been asked several times what clearance his engine has been set up with,he has declined to answer. I can only assume he does not know. He needs to ask his engineer if he can't measure it for himself. With this information members can give him the benefit of their experience which may stop him (and possibly his engineer ) making the same mistake a third time.

- Log in to post comments

Clearance

Sorry folks,

I have to ask the man from the engine shop for the clearance. When I got the barrels and pistons he bored it out for a clearance of 10 thou. After the first seizure it was 20 thou and now I guess 30 thou after the third honing.

I brought him my crankshaft for grinding with new oversize shells +0.10 this morning and collected the barrels nut forgot to aks which clearance they have now.

He wanted to know what is the correct torque for the big end nuts? Does anybody know?

- Log in to post comments

Big End nuts-Torque

My Original Electra Maintenance Manual specifies 15 foot pounds as the tightening torque for the big end nuts. I wouldn't think the Navigator will be any different.

I have just rebuilt an Electra engine ,I have only run the engine in the garage up to now for a few minutes but it seems quiet enough,no rattles or knocks Fingers crossed it will be OK when I get it out on the road.

Frank Anderton

- Log in to post comments

Hi Ulrich, 10,20 and 30 thou…

Hi Ulrich, 10,20 and 30 thou are the oversize of the pistons. What we are interested in is the final clearance between the piston skirts and the finished bore. This varies with the manufacturer of the pistons and the material the pistons are made of. Air cooled engines usually need more clearance than watercooled and some engines need a bit more clearance than expected due to poor lubrication or heat distorsion. or poor engine orriginal machining. There will be members here who have lots of experience with these engines and may be able to advise on what they have found to work. Its also very possible that your problem is down to overheating on that cylinder and your clearances may be ok,but it would help to know as much as possible .

- Log in to post comments

Hepolite service manual 1961…

Hepolite service manual 1961 gives lots of information about pistons and clearances and where to measure and how. Fascinating that pistons at room temperature are oval becoming round at running temperature. Skirt dimensions vary from bottom of skirt to top of skirt . All information is general and needs careful reading to help decide whats best.

GRAHAM

- Log in to post comments

I have no data or insight…

I have no data or insight into Navigators, but as no one is posting to advise Ulrich I would suggest that the clearance on the thrust face just below the bottom rings should be not less than three and a half thou. Any better offers?

- Log in to post comments

Looks about right to me…

Looks about right to me according to the data posted by Graham. If that's what it was, maybe add another 0.01"? Or two? The catalogue confirms that the piston should fit correctly if the over bore is correct, so the correction ought to be made in the piston. I don't suppose the machinist added 0.02mm instead of 0.02 inches (0.58mm)?? Then run in very gently to begin with. In olden days they might take the block off after the first hundred miles or so and file away any signs of hard polished marks! Allegedly.

- Log in to post comments

Mmm...

Following these threads from the very beginning I've wondered throughout whether the whole thing has been as a result of incorrect running in but assumed that it couldn't possibly be so. I do find myself wondering however about riding a newly-rebored and re-pistoned old 350 at 60 (mph? kph?). Stranger things have happened..

- Log in to post comments

Hi Howard, I fitted new…

Hi Howard,

I fitted new Hepolite pistons after a reborn and was advised not to exceed 1/4 throttle for the first 500 miles.

I duly marked the throttle openings at 1/, 1/2 and 3/4 with my sister’s nail varnish and stuck rigidly to the recommendation. On a return journey from Newcastle on a very long, slight downhill, straight the bike (Dominator 99) reached 90 mph without overload. It is more important not to stress the engine during running in than the actual rpm and speed.

Regards

Dick

- Log in to post comments

Hi David, If Ulrich gets…

Hi David, If Ulrich gets another 0.01" clearance added it will sound like my 99 !!. I think you meant 0.001 thou. IE one thou. When I had my 99 bored to plus 10 thou the engineer advised me that with 31/2 thou clearance there would still be some wear shadows on the bore. I opted for an extra thou ,IE 41/2 thou and put up with a little noise when cold. Sounds just like an old Brit should. I recently managed to properly overheat my motor with bad carburation but no lasting effects .There are now coatings that can be applied to piston skirts that wear away to give close clearances and quiet running, would like to try that. I would prefer a quiet engine ,but knowing that sooner or later I will "F" up somewhere ,a safety margin helps. Its also possible that the fully synth oil I am running helped to protect the motor.

- Log in to post comments

I must compliment Ulrich on…

I must compliment Ulrich on his patience and determination, many would have given up by now and sold it. I look forward to hearing the Navvy bellowing in rude health.

- Log in to post comments

Many years ago, when I had…

Many years ago, when I had my first motorcycle to ride around a field, my grandfather warned me about the piston seizing and what I should do. He then told me about his efforts to improve an engine on his vintage motorcycle when he was a young man. He obtained an aluminium piston to replace the iron one and one Sunday spent the day making it fit well.

Ride down the road until the engine is warm and then go flat out on a long straight until the piston starts to seize - whip in clutch and stop. Wait for it to cool down and ride back home. Take off barrel, remove piston and file it down where it had seized. Reassemble and go for the same ride, and keep doing this until it does not seize. He said it would take four or five times and then would be fine. What else would a working chap do on a Sunday? I was seriously impressed.

- Log in to post comments

From another thread,JP…

From another thread,JP pistons say 4 thou at the bottom of skirt .

- Log in to post comments

Running In

Quite so Dick. My observation was prompted by Ulrich's statement " I was doing 60mph when the engine sounded stressed and I pulled the clutch." with no indications as to throttle openings, road conditions, perceived engine loadings etc at the time - level road, slight upgrade, headwind, constant throttle opening? Who knows? (other than Ulrich himself of course.)

- Log in to post comments

running in

Howard,

the road was level, no uphill, with big radius bends, almost no headwind and constant throttle (about half open) for about 3-4minutes before the engine seized.

Unfortunatly my mobile phone had no connection, so I walked about 1/2 mile in each direction with no result getting connected to the world.

When I came back to the bike there was an SUV stopping with a customer from the optician shop I work in. He saw me walking and turned around. He gave me a lift back to my workshop where I could phone my daughter and her boyfriend. He got a van to take the Navi home.

Today I wrote to the engine shop to tell them the correct torque for the big end nuts and I asked for the piston clearance.

Will report!

- Log in to post comments

Running In

I'd like to make it clear, Ulrich, that I'm not offering myself as an expert on running-in techniques, although I can claim to have effectively run-in getting on for a dozen engines in my time. Having said that, the one point in the details given above of the circumstances in which the seizure occurred that I might query would be the use of a constant throttle opening for about 3-4 minutes. How many miles had the newly-rebored engine done by that stage? In my own case I'm almost paranoid about varying the throttle openings during running-in, especialy so over the first couple of hundred miles and I also like to briefly let the engine rev with very light loading during that particularly critical phase. As I say, I don't claim expertise, just offering my thoughts in the matter.

- Log in to post comments

My mate bought a brand new…

My mate bought a brand new Ducati 250 Mach1 back in 1965. The very experienced Mechanic Bert Furness said it was a tight motor and would need 2000 miles to run in. I eventually got it up to a calculated 104mph. It was as quick as a Dominator. But very fussy. Pretty much identical to the 250 that Won its class at the 24hour Endurance race in 67 and came 3rd overall. I have one still.

- Log in to post comments

Piston clearance

Today I measured the piston clearance with a feeler gauge:

Piston clearance in barrel without rings is between 0.2mm to 0.25mm.

Still waiting for the qoute of the engine shop owner.

The engine had about 20 miles on it when the seizure happened.

I will be a lot more careful when the engine is back in the bike.

- Log in to post comments

To echo some of the advice…

To echo some of the advice above Ulrich, from bitter experience of seizing a freshly rebuilt Jubilee engine twice in similar circumstances many years ago I personally wouldn't dare run a freshly rebuilt Navigator at 60 mph at any throttle setting until I had done at least 100 miles and re-torqued the head down - in my experience running it that hard with only 20 miles on the clock makes a seizure almost inevitable. I would start by limiting myself to 40 mph, regularly varying the throttle and revs and not letting the engine labour or run too hard and fast for any period of time. After 100 miles I would slowly build up to it varying the speed and throttle setting to make sure I am not pushing the engine too hard for too long or letting it labour until changing the oil at 500 miles. I would still take it easy until 1000 miles but every engine is different. For example I cruise my Navigator at a maximum of 55 to 60 mph even though it will pull willingly up to over the legal limit - but in deference to it's age and 50s / 60s technology I only do that very briefly. It has a very well run in engine with many thousands of miles on the clock, the carburation and timing is spot on and I have built up my confidence of the engine's health over three years of careful maintenance and riding. Good luck and I really look forward to hearing of your success with what I am sure will be a totally rebuilt and reliable engine once you have finished! Nick

- Log in to post comments

Running in

I'm sorry to say that, apart from the other problem's he's found, I am fairly certain that Ulrich's main fault is in not following the critical running-in procedure. I'm not at all surprised that his bike seized at 60mph! Much too fast if it had done less that 1000 miles since rebore! The workshop and third-party manuals are very clear on that.

For the first 500 miles keep the throttle opening below 1/3rd, and change the engine oil at 250 miles. Haycraft says you should "nurse the engine very carefully during the first 1000 miles." Keep the revs down and never let the engine labour - use the gears fully. Don't hang on to top gear when going slow. Never let it tickover for more than a few minutes when the bike is stationary.

Norton Motors recommended using a running-in compound with the oil - it contained colloidial graphite. I certainly used it and had no problems.

Obviously all the other running-it procedures must be followed including changing gearbox oil, re-torque the head and barrel bolts, check/adjust valve clearances, contact breaker, brakes, chains etc. etc. In other words READ THE MANUAL! It's a great shame to see all your work almost go up in smoke because you lacked patience.

- Log in to post comments

Navigator seized

I was always of the belief that Hepolite pistons had the clearance built into the piston. This was so that you could buy say a nominally 80mm piston and the cylinder when bored to 80mm would have the correct running clearance on the piston. I have had pistons made for my Atlas by American firms and asked them to make a piston to fit a certain bore size with the clearance on the piston not in the bore and that allows the maker to give what clearance he wants his piston to run at. As a general rule throw away all the super techo measuring gear and use .001 feeler gages to measure your clearance. Beware of tapered bores, sometimes a result of worn boring equipment

- Log in to post comments

Hi Uli,

Sorry to see your seized Navi piston. What a nightmare!

Please check your ignition timing. The correct figure is 24 deg BTDC (Before Top Dead Centre) fully advanced. Check this with a strobe. You will see other figures quoted in various manuals BUT 24 deg is the correct value for a Navigator.

Make sure you find Top Dead Centre accurately - using a piston stopper. If you try to judge TDC by feel - you could be as much as 5deg out. The Navi (& its sisters Jubilee & Electra) have very short stroke engines and the timing has to be spot on!

See instructions attached - if you still have points.

If you have electonic ignition, follow the setup for finding TDC, then follow your makers timing setup instructions.

In both cases - you must check the setup with a strobe - revving the engine to check that a) the advance curve is working, and b) that the advance is not going higher than 24deg.