THE OVERHEAD CAMSHAFT NORTON

The Norton overhead camshaft engine is probably one of the most famous motorcycle engines ever made, spanning 5 decades. The engines came about from racing, something for which Norton will always be famous. In fact, a Norton has competed on the Isle of Man every year since the first TT race in 1907.

How It All Began

The engine was designed by Walter Moore during the winter of 1926/27 with its familiar dimensions of 79 x l00mm and was initially tried out by Stanley Woods in Germany in early 1927. It broke down. One part of the design which never changed was the use of bevels for the camshaft drive, but early on tooth failure was a problem, a problem which was to reappear later.

The bottom half of the engine was based on the existing Model 18s but there the similarity ended. The camshaft was driven by two pairs of bevel gears and a hollow vertical shaft. The bottom gears were contained in a blister on the crank case and the top pair were encased in an aluminium cambox with the magneto placed behind the engine.

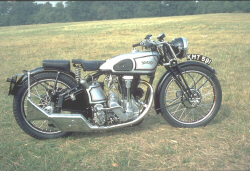

Moore's creation boasted an entirely new cradle frame with three chainstays, a fine three gallon saddle tank, and a six pint oil tank. This together with Webb forks with adjustable side dampers, a new three speed footchange gearbox, and front and rear 8 inch brakes, gave this Norton the lusty look of a real thoroughbred. The new engine was soon to prove a winner and the 1927 Senior TT was to give this OHC engine the first of its many victories.

For 1928, the CS1 (or Camshaft Model One) was born,selling for £89.00 and aimed at the racing or sporting rider. During that years TT the CJ (Camshaft Junior), a 71 x 88mm 350 was tried out but proved to be too slow. Few changes were made in 1929, but problems arose that were all too familiar - engines fine at first and then starting to slow, probably caused by a re-designed combustion shape. This eventually resulted in Walter Moore leaving the Norton camp and going to N.S.U.

It is generally understood that Walter Moore received a better financial offer from N.S.U. which he decided to accept. He personally owned the design of the OHC engine which he proceeded to make available to them and they later produced a Norton lookalike OHC engine. This prompted Norton to redesign their own engine.

It is generally understood that Walter Moore received a better financial offer from N.S.U. which he decided to accept. He personally owned the design of the OHC engine which he proceeded to make available to them and they later produced a Norton lookalike OHC engine. This prompted Norton to redesign their own engine.

The First Redesign

Arthur Carroll took over as Chief Designer, assisted by Edgar Franks and a Norton rider/development engineer, Joe Craig. Carroll, a draughtsman, together with Craig designed the now famous 'Carroll' engine which first appeared at the North West 200 in the spring of 1930.

This engine incorporated extensive changes from the Moore design but still retained the original bore and stroke. Then for 1932 the International appeared in both 490 and 350cc classes, and a name which was to represent world-wide sporting success was established.

During the 1930s the design changed little although coil valve springs were replaced by hairpin springs on the works bikes because of breakage (to be followed later on production models). Different materials such as magnesium and ally-bronze were used, helping to improve engine performance by reducing its overall weight and rolling resistance.

The touring CS1 continued into 1934 with its three speed gearbox but with the option of a four-speed hand change. The road type magdyno was fitted as Inters had a racing BTH magneto together with Norton forks in place of the earlier Webb type. Later, the touring CS1 and CJ (which also used the 'Carroll’ engine) were given the four speed gearbox as standard, but the positive stop mechanism remained an option.

Also in 1934, the oil supply was increased and the gearbox received a neater positive stop mechanism. The CS1 and CJ changed to the Norton forks and were fitted with the familiar one piece hub and drum front wheel used on the racing machines, with the narrower front fork to suit it.

For 1935, hairpin valve springs were specified and the petrol tank was increased to 4 gallons and the oil tank to 7 pints. The gearboxes were now of a new type built by Burman and virtually copied from the Sturmey-Archer design except for a fully enclosed positive stop mechanism. This cluster was to be used virtually the same in the Commandos during the 1970s.

During 1936, the works bikes used a plunger-type rear suspension but for all others solid rear ends were the norm. From late 1937, selected riders were given the new plunger type rear suspension but without all the lightening holes.

From 1938, the plunger rear suspension was available for an extra £15, and approximately one third of all Internationals were built to racing specification as standard. Works bikes (probably influenced by BMWs) now used undamped telescopic forks.

In 1939, the Norton racing Internationals were at their best with plunger rear-suspension, large tanks, square type cylinder head and megaphone exhaust, this was the classic garden gate Norton and probably the most sought-after garden gate Manx today. The difference between racing and road machines was now more noticeable. The CS1 and CJ became less sporty whilst the International and International to racing specification were classed as real thoroughbreds; a few 600s were built for sidecar racing.

In 1939, the Norton racing Internationals were at their best with plunger rear-suspension, large tanks, square type cylinder head and megaphone exhaust, this was the classic garden gate Norton and probably the most sought-after garden gate Manx today. The difference between racing and road machines was now more noticeable. The CS1 and CJ became less sporty whilst the International and International to racing specification were classed as real thoroughbreds; a few 600s were built for sidecar racing.

The works were always trying new ideas - an enclosed valve spring version of the 350 engine was tried (gaining 10th place in both the Junior and Senior TT of 1937) but sadly, never put into production due to the inaccessibility of the valve springs which might need to be quickly changed during a race. However, one idea which reached production after a decade after its fruition, was the double overhead camshaft. It was tried in practice for the 1936 TT and then used in the 1937 TT and was to become standard equipment for production racers in 1949.

In January 1939, Joe Craig who had been involved in the development of the OHC engines since 1929, left Norton to join BSA and Norton eventually pulled out of the works entry racing. A racing International with telescopic forks was catalogued for 1940 but never produced. The ‘over-the-counter' Model 30 (500cc) and the Model 40 (350cc) Internationals continued with steady sales and were more popular than the CS1 and CJ versions which were dropped from production after 1939.

After six years of war, during which the factory had been fully engaged in the war effort, production returned to normal. During July and August 1946, the first purpose built racing Inters (now catalogued as ‘Manx Norton’) were produced with the first Inter following in September and receiving the new A11 code. (The letter A represents the year 1946 with B for 1947 and so-on). Due to 'pool’ petrol only being available, compression ratios had to be drastically lowered.

By 1947, Joe Craig had rejoined the Company. Gilbert Smith, now Managing Director, was keen to build on Norton racing successes and the U.S.A was considered an important and popular export market. In the spring of 1948 Steve Lancefield was sent to Daytona to assist the Norton riders. The American Motorcycle Association (A.M.A.) insisted on catalogue models which had to be fitted with a kick start so Norton fitted the low ratio International 1st. gear pinions. As a result, one or two riders came to grief due to the retarding effect of the bottom gear which was to prove too severe. This problem was later resolved when Burman developed a special higher ratio 1st. gear pair with kick start. This became known as the ‘Daytona’ 1st. gear and was well sought after by road riders to close up the huge gap between 1st. and 2nd. gear.

The 1948 TT Nortons were basically still the pre-war models with increased finning on the square heads and barrels. The Internationals and Manxs remained little changed until 1949 when the double overhead camshaft became available for the first time other than on works engines and this was based on the 1937 works machines.

The Featherbed Era Dawns

The year 1949 was not good for the Norton team. Harold Daniell won the Senior TT by default - the works AJS broke down although they (AJS) won the 500cc championship and the 350cc Nortons were outclassed by the swinging-arm Velocettes. The garden gate frame was always breaking and beginning to show its age.

However, the tide was about to turn when Rex McCandless working in Belfast built a new type of frame using a welding process which had been developed during the war. This was Sif-bronze welding, which uses an alloy which melts at lower temperatures, but has high tensile strength and can be built into fillets. A works 500 engine was mounted in the new frame and taken to the Isle of Man for testing using a garden gate Manx for comparison. Artie Bell on the 'new' Manx proved faster than Geoff Duke on the works bike. Further tests at Montlhéry near Paris proved the new frame beyond doubt.

In January 1950, Rex McCandless with Edgar Franks from Norton, took the frame and Rex's jigs to the Reynolds Tube Company where Ken Sprayson built the first Reynolds frame. Once approved by Norton, Reynolds constructed their own jig and fixtures on which all subsequent frames were built and were instructed not to make public the fact that Norton were unable to manufacture these frames. Nevertheless, it was soon to become common knowledge as to the origin of the frame. At the 1950 Junior TT prize-giving Harold Daniell remarked that the new bike was so comfortable that you could go to sleep on it - rather like being on a feather bed - and so created what is now history.

The general public were still using the old frame with the International little altered, although it could be specified with aluminium barrel and head. This together with the magnesium Manx cambox and the advantage of central feed to the cams was how the clubman bikes were equipped. Thanks to Leo Kuzmicki who understood cylinder head and cam design the Manx had the twin cam engine as standard which gave it a little more power.

During the Autumn of 1950 it was announced that the Manx would feature the new type frame as standard and which would become generally available in the Spring of 1951. The Motor Cycle certainly approved, claiming that this was as near as you could get to a pukka works bike. However, only established riders got the new Manx of which 58 were produced in 1951 and soon proved to be quite exceptional. The engine was still the long stroke with modified crankcases known as the ‘tall’ crankcase. A few Manxs remained unchanged for Daytona mainly to satisfy the A.M.A. whose resistance to the Featherbed frame had been so severe (popular belief has it, that this resistance was to enhance the winning chances of the Harley-Davidsons).

There was little change until 1953 when the Internationals received a bolt-up type Featherbed frame akin to the Manx frame. Although not the same grade as the Manx, it was the same gauge. The Manx frame was made from Reynolds 531 and the International frame from Reynolds Grade ‘A’. The engine of the Inter was now all alloy with the Manx magnesium single cambox and contents as standard.

Clubmans Successes

Some 58 Internationals were manufactured in 1953; most were destined for the Clubmans TT, and featured Manx footrests, dropped handlebars, open pipe and other racing details. They were very successful with Norton taking the first three places in the Senior and R.D. Keeler riding at an average of over 84 mph.

Until 1954, standard Manxs had changed little except for slight improvement on engine performance brought about by ideas tried out on previous works engines. This year was to prove a significant change for the Manx. The works team had been using short-stroke engines for some time, but now the ‘over-the-counter’ engine was dramatically changed. The 500 was now 86 x 85.8mm and the 350 was 76 x 76.85mm.

The works engines had reached their final design and caused quite a stir with two major developments viz. - oil cooling of the exhaust valve guide using an oil of S.A.E.20 and a weir type carburettor from which surplus fuel was pumped back into the tank.

Another interesting Craig feature for 1954 was fitting a single external flywheel instead of the traditional double internal flywheels (influenced by Moto-Guzzi). The main object was to reduce the overall height of the engine without an undesirable reduction in flywheel inertia. Dispensing with the internal wheels permitted the connecting con-rod length to be reduced proportionally to the shortened stroke with engine dimensions becoming 78 x 73mm (349cc), and 90 x 78.4 mm (490cc) The engine shock absorber differed from the standard in that where as the standard Manx used a clutch type, the works used a type (first appearing in 1931) in the engine sprocket. The frame differed from standard in several ways. The bottom nearside main frame tube was kinked to clear the flywheel, the main loop of the 500 used 16 gauge and the 350 used 17 gauge. In addition, one of the nearside subframe tubes carried oil for lubricating the rear chain. Oval tubes were used on the swinging arm probably to enable a wider rear tyre to be used.

The Burman Gear Company built specially for Norton, a five speed gearbox which looked quite different from the standard type, but was never trouble free. Another feature which the standard Manx never had was a rear brake assembly separate from the sprocket.

The standard Manx with its square engine now had a twin leading shoe front brake and the rear sub-frame was welded on, as had been the practice on works bikes since 1952.

The End Of An Era

At the end of 1954, Norton announced that they would no longer be giving full works support for Grand Prix racing. Instead they would now use standard machines but incorporate development features for the next seasons models. Not all events would be contested. This announcement came just as they were developing a Moto-Guzzi type laid down single cylinder known as the F-type (Flat Engine). This new racer was under test at MIRA where it immediately produced more power than the old engine. The horizontal engine ran backwards with a five speed gearbox. The frame was a new type having a larger diameter spine tube which was also the oil tank. This machine can now be seen at Sammy Miller's Museum in New Milton, Hampshire.

The 1954 Inters were virtually the same as the previous year except that only a few were for Clubmans and almost all went abroad with Australia and New Zealand receiving quite a few. The following year saw very little change in either the Manx or Internationals although the Inters now had the rear sub-frame welded on as was the Manx. Very few Inters were now to Clubmans specification, and almost all went abroad. The Inter was also now available in black trim and most of these went to Australia. The end of the year saw the resignation of Joe Craig. He had been there since 1925 except for a wartime break and was tragically killed in a motoring accident near Innsbruck in 1957.

The 1956 Manxs were now benefiting from the works production development models. The frame was now in its final form with a small rear loop, phosphor bronze bushes for the swinging arm replacing the Metalastic bushes, an oil reservoir in the nearside frame tube for lubrication of the side plates of the primary chain, and a rear chain buffer guide. The forks were also altered by shortening the stanchions in conjunction with a different pair of fork yokes, the top being a ‘dropped’ type. The engine had some more improvements with new cams and higher compression ratios and b.h.p. output was steadily rising creating further problems.

The Inters still retained the single-sided brakes, although the other roadsters had been using full width hubs for a year or more. Production of the Inters slightly increased with 1956 being the peak year for the Featherbeds. There were plenty of extras to be had which were mainly Manx parts. Even those parts not normally listed such as the Manx twin leading brakes were occasionally fitted, but the true Manx frame was never used. More Inters were sold to the home market than ever before, which explains why most of the UK Inters are post-1955 models.

The most significant change to the 1957 Manxs was that the bevels were redesigned. They were now produced with a coarser pitch because as power and revs increased the finer type of bevel would break. To the surprise of many, the works turned out with a few '90' bore machines based on the Craig 1954 engines but with internal flywheels. These were designed by Doug Hele who had rejoined Norton along with Bert Hopwood, the designer of the twin cylinder Dominator Engine.

The Inters were down on production compared to the previous year but were still subject to some development. Compression was now up to 8.4:1 for the 350 and 8.1:1 for the 500. A new silencer replaced the pear-shaped one and this helped to extract a bit more from the stifled performance. As these engines were now almost long-stroke Manx engines, a silencer became much of a hindrance. The early type cast iron full width front hub was now used in addition to the full width rear. The petrol tank now had bolt-on chrome panels and the headlamp arrangement was tidied up. Although the Clubmans had all but finished, a couple were still built but not entered.

No More Inters

In 1958 the Manx gearbox was changed to the AMC type which the roadsters had been using since 1956 but differed from this by the clutch operating mechanism. The Manx had a far superior roller and cam lever device, very similar to that of the lightweight Jubilee system. An improved clutch accompanied the new gearbox with its adjuster in the outer pressure plate.

This year also produced another full batch of Inters with the familiar D type footrest finally being abandoned. These Inters were to be the last of a long and illustrious history which spanned 25 years. The improvements which had taken place over the years had started to stagnate. For example, the Inters were still using the laid down type Norton-Burman gearbox long after the rest of the roadster range were fitted with the AMC type, and no further development was to take place. Production ceased but some 40 years on there are still a few of these last Internationals around today.

Hele's New Engine

By 1959 Doug Hele was back in charge of the Manx's development and would be responsible for both the racing and production models. He had been working on a desmodromic Manx engine which had fierce cam profiles making quicker opening and closing of the valves.

However, the extra load on the vertical drive soon caused it to fail. The drive was redesigned with an extremely strong and simpler layout. He decided to adopt this design for the production Manx. In this the bevels were splined to a larger diameter vertical shaft which ran in needle roller bearings and the lower bevel housing was quite radically changed having a light alloy tube casting. This means that the pre and post 1959 engines are quite distinguishable and it has become a matter of opinion as to which looks the better engine.

When the 1960 season dawned it soon became apparent that Hele and his team had not been idle for although design changes were relatively small, reliability and performance had improved. A better big-end assembly, Stellite was used on the tappets, higher compression ratios and glass fibre used for the first time on the seat assembly thus reducing weight all played their part in the improvement. The Dunlop alloy rims were finally abandoned to be replaced by Borranis. With 57 500s and 48 350s built during this year, the Manx production remained steady.

Further improvements were made during 1961 with the piston shortened to two rings and thus shortening the barrel. A new type of Amal G.P. carburettor was used replacing the pilot adjustment for fuel to air by using the Monobloc pilot system. This resulted in better starting and slow speed pickup, particularly out of corners. The oil tank was completely redesigned to the rhomboid shape and suspended from rubber bushes and held by a thick rubber band against a rubber pad. The swinging arm pin was now a much larger hollow pin with a greater surface area and less weight although some top flight riders like Phil Read preferred the solid type as the greater hole in the gusset plate caused flexing.

It's All Over (almost)

The following year, 1962, was to be the last full year for the production Manx with the most obvious change being the front brake now a 7 inch diameter twin leading shoe, dual drum component with a surface area a little over 71 square inches. Some riders found that the old 8 inch twin leading shoe was a bit lacking, particularly when coming down the mountain on the I.O.M. The only disadvantage was the increase in the unsprung weight. A larger capacity oil pump and a cut-away at the rear of the petrol tank for the 500 were additional improvements.

In July, the news broke that Norton were leaving Bracebridge Street. AMC were not doing too well and production was to be transferred to Woolwich in London. Doug Hele decided to go and left in 1962. Manx production stopped during August 1962 but restarted again in November. 42 were produced between November 1962 and January 1963. Some of these were unsold and were moved down to Woolwich where they were stored as complete machines and gradually sold off during the year. With AMC fully in charge the Manx was now finished and spares gradually dwindled away.

During 1966 Colin Seeley purchased what remained of the spares and tools and which eventually moved on to John Tickle in 1969. Tickle went on to produce and build entire machines incorporating a few of his own detail modifications, and these were redesignated the Manx T5. He was subsequently to manufacture his own frame, similar to that of the Norton, but much lighter; this in addition to manufacturing new engines and spares

Unfortunately Tickle's business slumped in the early 1970s and Unity Equipe bought the Manx rights and provided the spares service. Very recently Andy Molnar has purchased the rights to the Manx name and some original tools and spares from Unity Equipe. The Manx is now in complete production again thanks to enthusiasts like Andy Molnar, the Summerfield brothers, Bernie Allen and Ken McIntosh; so bikes and spares are in a better state than they have been for many years.

Epilogue

Today, many Manx Nortons can still be seen battling round the circuits of the world and of course the Isle of Man. Many clubs now cater for the Manx on these racing circuits and the Annual Norton Owners Club Solent Branch Thrash at the Goodwood motor racing circuit always gathers a good turnout of camshaft Nortons. There is now a trend for part or complete replicas to be raced, with originals being more cosseted although some do still appear on the circuits to be raced.

Quite a few Inters are still on the road with riders still fighting the losing battle to keep oil inside the cambox and not outside. On the road is where they should be, just as the manufacturer intended.

It has not been possible to list every alteration in detail on the overhead camshaft Nortons, but finally -

No. 105048 are you out there somewhere? - for you are the last Bracebridge Street Manx

© Barry Stickland

Originally published in the Norton Owners Club Classic Calendar for 1998