Later (alternator models '57 onwards, possibly) OHV singles had an anti-wet sump valve incorporated in the outer timing cover. This was a spring loaded ball on the outlet side of the oil pump. Two questions: Was this effective? Is it possible to retrofit this valve to earlier (dynamo) timing cases?

Cheers, Ian McD

58 onwards on the twins.

- Log in to post comments

service your oil pump

A year or two ago, there was an article in 'Roadholder' about servicing your oil pump. It really does make a difference in preventing or delaying wet-sumping. I did this on my Dominator, which has the same pump design as the non-ohc singles, tho' I hear it's a mirror image.

If you examine a worn pump body using a metal straight edge and feeler gauges, you can expect to find that several thou of feelers will pass under the straight edge. You need to eliminate that. So, lap the pump body until the pressure pump gives light friction when assembled with a smear of oil. I also did this with the scavenge pump, though this is less critical than the pressure side. To do this, you need to lap the pump body on wet-and-dry paper on a sheet of glass. I think I started with 120 grit and went to 240 and then 400 to finish - but it was a long time ago that I did it. Do keep checking that you are lapping the pump evenly, not creating a taper on the body. My pump only passes a little oil if I don't use the bike for a month (shame...), and gives 40-odd psi at a fast idle when well warm.

- Log in to post comments

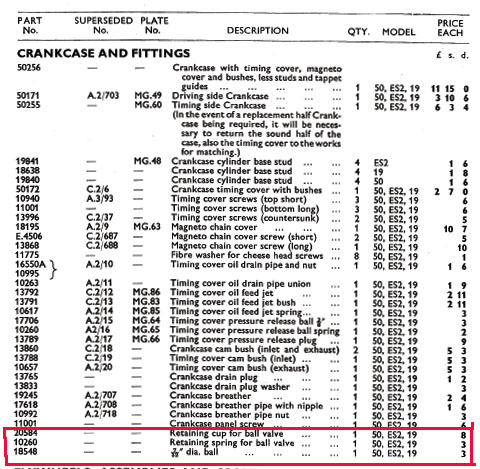

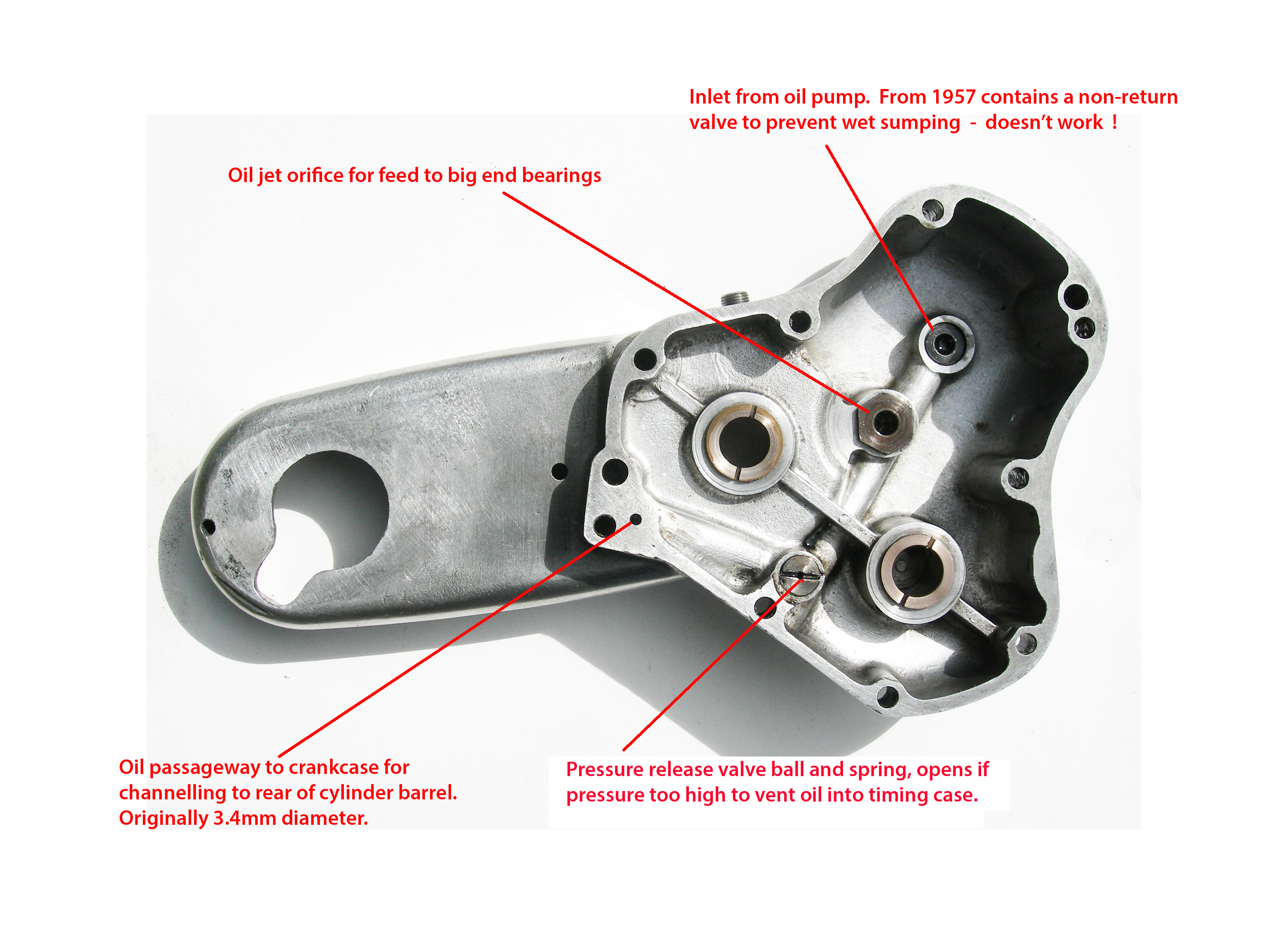

Timing Case Photo

The attached photo shows alternator and dynamo outer timing covers. The alternator version has a ball valve fitted in the first node of the oil gallery. Was this a standard Norton fitment for the later singles, or is it a DIY fitment by an owner trying to prevent wet sumping?

I appreciate the comments about the oil pump needing to be in good condition, I am aware of that. My questions were prompted by seeing the ball valve in the alternator case, until very recently I have looked only at dynamo engines.

- Log in to post comments

Hello Ian,I think the…

Hello Ian,

I think the origins of the built-in anti drain valve came up a few years ago on this forum when I queried this aspect myself. As far as I can tell, I believe it was introduced from 1957 but my own experience was that it didn't seem to work. The components were still listed in the 1962 Parts Book.

I had a built-in valve on a 1960 ES2 and a M50, but not on a mid-1957 19S, which would seem to tie in with the 1957 Parts Book, for the first time listing the components, but not shown on the exploded view.

With regards retro fitting with possibly more effective spring/ball components I decided against the risk of ruining an original timing cover, settling for a couple of Mick Hemmings valves on the M50 & 19S and a tap+ignition cut-out on the ES2.

- Log in to post comments

My '61 ES2.................

...............never sumped up, even after sitting for 2 years in storage.

- Log in to post comments

That’s funny as my…

That’s funny as my alternator engine wet sumps, my earlier one doesn’t - both have new oil pumps! I just live with it!

Dan

- Log in to post comments

Curiosity satisfied

Thanks Peter, that is the sort of info I was hoping to see. No point in considering mods to the earlier case if it doesn't work. I have been living with wet sumping for many years, and will carry on with the minor inconvenience. If the bike was used daily, as intended, it would never be an issue. At least it is a bit slower since fitting a new pump. The Kingpin style oil tap with magneto cut-out is probably the most effective (and least risky) solution.

Cheers, Ian McD

- Log in to post comments

Hi Phillip The engines were…

Hi Phillip

The engines were built by Mike P, I’m not sure where he gets them from prob RGM or Andover.

Dan

- Log in to post comments

Hi Ian, long time no see.(Since IOM MGP 2017. Almost 4 years since we lost Kiwi Mark. (8th)

In my experience the only real cure, apart from a tap, I'll not even think about, is a perfect oil pump.

For my final build (Dommie Racer) I had a precision engineer machine new gears (Supplied by RGM) to the exact specifications. The new RGM gears are specifically over sized so you can do this.

Almost a year with oil in the tank and no sumping.

The problem with the ball and spring is they can stick, usually with gunge and often overlooked.