Hi guys... My 650SS restoration is progressing apace. I had the bare crankcase and cylinder head from the original matching numbers engine. The other major engine parts are coming from a donor engine that had been "tuned for racing". It was a mish-mash of parts from various years.

I'm currently concerned with the oil pump. This is a six start worm gear variant. The con rods were earlier ones with no oil relief holes. These have been changed for later ones that have the oil relief hole. The rocker spindles were the scrolled type, now changed for plain ones. The rocker oil feed is from the timing cover tapping.

I've read about these engines "over oiling" the cylinder head. I assume that the exhaust side is ok as oil can presumably return via the pushrod cavities. It's the inlet I'm concerned about. Mention has been made of enlarging the drain holes to improve the return flow

Is that necessary, and if it is, by how much? Any help or guidance would be gratefully received.

Thanks, John

Hello John - You don't…

- Log in to post comments

Ok... The cases are, judging…

Ok... The cases are, judging from the engine number, late '62/early '63 -

Engine # 18 SS/105642/P

- Log in to post comments

John you're quite correct…

John you're quite correct. Your crankcases are early ones and would have had the standard SS oil pump which had an S stamped on the front. The oil feed (and scavenge) at the junction block would have been 15/64 inch and this hole size would be followed through the oil ways. The later 650s (and Atlases) that had the pressure fed rockers also had the double-speed oil pump gears. The oil feed, at the much bigger junction block, has 5/16 inch feed (and return) holes, flexi-tube inner diameters and these sizes are carried through the oil-ways in the crankcases. So the feed and scavenge of these models was much greater than your model. These measures alone meant that there were breathing difficulties so extra holes and larger holes were needed to stop over-oiling and many leaks. Doing some of the modifications may improve the original design but ... there are risks associated with this approach. Cam wear, cam-follower wear , short-lived big-end shells, main bearing failures, piston collapses, rocker failure, bad leaks, smoking running and even con-rods thrown through the cases are some of the failures that have beset me tuning and racing 650SS and 750 Atlas engines. Good luck, Howard

- Log in to post comments

Wow, Howard.... don't beat…

Wow, Howard.... don't beat around the bush, tell it like it really is!!!

If that's what I've got to look forward to, I think I'll stop right there, take the whole thing up the tip and buy a Triumph!

Does anyone have any good new... please?

John

- Log in to post comments

Better News

When I was young and innocent and putting in big mileages on my 99 I fitted 6 start worm gears to the oil pump. What problems did this throw up? None whatsoever. Later on I fitted a 650SS head with the pressure feed to the rockers. No problems there either.

You can over-think things.

- Log in to post comments

For me

Hi John,

My 650 is a bit of a mongrel in that all the engine is Norton, but most bits left the factory at different times.

When I first got it, I was led to believe that it was necessary to 'upgrade' to the positive lubrication of the valvegear and so did that. The result was that you couldn't do more than about 5-8 miles before it looked like a 2-stroke from behind.

As Howard said, the pressure feed mod isn't just a 'plain spindles and positive feed' thing, the oil drains were changed too.

Moving on, I reverted to the original set up of oil feed from the return line and it has been fine since.

Best mod I have done was to delete the 'Maltese cross' from the end of the cam and put a reed valve on the crankcase vent line. Well worth considering as crankcase breathing is marginal at best on a 650.

Regards,

George

- Log in to post comments

Sorry if I've thrown a…

Sorry if I've thrown a spanner in your plans John. On a road steed it is often better to stick to the design that Norton' s engineers developed for years before releasing the bike to the market. After al, if they were good enough to compete and win 500 Mile races at Thruxton etc then there was not too much to worry about. The problem comes when embodying later modifications. Sometimes a part embodiment does not function as if the whole mod was completed. When Paul Dunstall started selling the six start oil pump gears it was seen as a must-have item for many Dominator owners. He had developed these items on his Domiracers and believe me there was much more to it than a pair of gears to speed up the pump rate. Depending on what other tuning areas you have inherited and any wear on the other components may give you issues. Over-oiling with pressure fed rockers is a common problem even with plain rocker spindles. Oil lurks at the back of the head around the inlet valve and if it doesn't drain quickly enough has a habit of going down the guide. Larger oilways were required to assist with draining away the excess oil. Con rods with the oil bleed holes are stronger than the originals if you use the shells with the holes to suit but remember this mod puts a lot of oil on one side of the piston to stop seizures when running very hot and if your rings are not up to it some of the excess oil will by-pass the ring and burn. Nortons introduced this mod with Wellworthy "Duaflex" piston rings to stop this problem. Remember the holes in the rods need to face inwards so that they face each other. At the least you should consider opening up some of the scavenge holes and fitting larger internal diameter tube to the return side of the oil flows to help with pressure problems that cause leaks and oil burning. On a road bike i would agree with George and not have the high pressure feed to the rockers. Early Commandos had to fit top-hats to the valve guides to help cure over-oiling and that was chaotic when they disintegrated. Good luck, Howard

- Log in to post comments

Thanks for all the replies…

Thanks for all the replies. I apologise if I come across as a bit of an idiot, but I've never worked on a Norton twin cylinder engine before and have no previous knowledge to fall back on. (Service Notes, Haynes manual and Mr Bacon don't necessarily give all the answers) I'm still a little confused, however, but that's my normal state, I'm afraid. At best my engine is going to be a bit of a "mix & match", but at this stage, I seem to have options.

So far, only the early crankcase (with the smaller oilways) has been built up, using later conrods with the oil bleed hole. I really don't want to strip that down again to put the old conrods back in, so the later ones are staying. I've bought a "good" second hand oil pump from a reputable dealer, but it doesn't have an "S" stamped on it. It does have a gear for a 6 start worm nut fitted. I have a useable 6 start crankshaft worm nut. Is there anyway of telling whether the pump has the larger internal gears without taking it apart?. I have both plain and spiral rocker spindles, so I can use either. I can also use either the timing cover tapping or the return oil tank union to feed the rockers.

As the general consensus seems to be that the 3 start system is perfectly adequate, I guess that the sensible option would be to use 3 start gears on the pump, spiral rocker spindles and feed the rockers from the oil tank union. Only one problem... While I can get a 3 start crankshaft worm nut reasonably easily, a search online has failed to find anyone with a matching 3 start oil pump gear for sale. If I stick with the 6 start pump, could I still use spiral rocker spindles, fed from the oil tank union to lubricate the rockers to avoid any cylinder head over-oiling problems?

So many questions... :-)

- Log in to post comments

"Remember the holes in the…

"Remember the holes in the rods need to face inwards so that they face each other."

Howard... that contradicts all the other information that I've read that state categorically that the oil holes should face outwards.

- Log in to post comments

Oil Holes

Check out these words of wisdom from a Haynes Manual. Personally I am with Howard in that by facing the oil holes at each other the oil sprays cross and lubricate both sides of both cylinders. Rather than just the exhaust sides.

Adding a little more information from my own records. The Slimline frame is probably pre-1965 as it shows the bolt that holds the upper gearbox cross-tube in place. This was welded in position from 65 onwards.

John's 650 engine is more interesting. The number indicating a spring 1963 motor which would make it from the first batch of Plumstead produced 650 engines. The AMC factory was plagued with machining problems resulting in skip loads of rejected heads and crankcases.

This engine would have left the factory with scrolled rocker spindles fed by a 3 start oil pump and low pressure oil return feed. The draw back of this set-up, in the early 650 motors, was the time it took to get oil properly circulating along the spindles. With the inside ends remaining dry for quite a time while the scrolls grounds away at the rocker innards. Any owner going down the conversion to plain spindles and high pressure feed must check the clearance between respective parts otherwise oil will have an easy route straight to the rocker boxes and valve guides.

- Log in to post comments

John - Throw away the Haynes…

John - Throw away the Haynes manual and get yourself a copy of the Dominator Service Notes from the NOC Shop or use the website to read it as required. There are many errors in the Haynes manual so don't rely on it. If you don't want to use the bleed holes in the con-rods reverse the top shell with the hole, with the bottom shell without the bleed hole. You'll get there eventually have no fear. Keep using the Forum when you're unsure about things. Howard

- Log in to post comments

Hi John, With the higher…

Hi John, With the higher flow and pressure that the gears give you will probably get enough oil to the rockers even with the low pressure feed.If you go back to the 3 start set you can always adapt the tank return hole size to increase oil to rockers if they look dryish .

- Log in to post comments

Oil Pressure

Several factors need to be considered when using the 3 start oil pump set-up. Even with the 'S' oil pump this must be in tip-top condition and not have a worn return feed as many older pumps tend to have. You definitely should not use conrods with bleed holes in them unless the holes are blanked off. As Howard points out above.

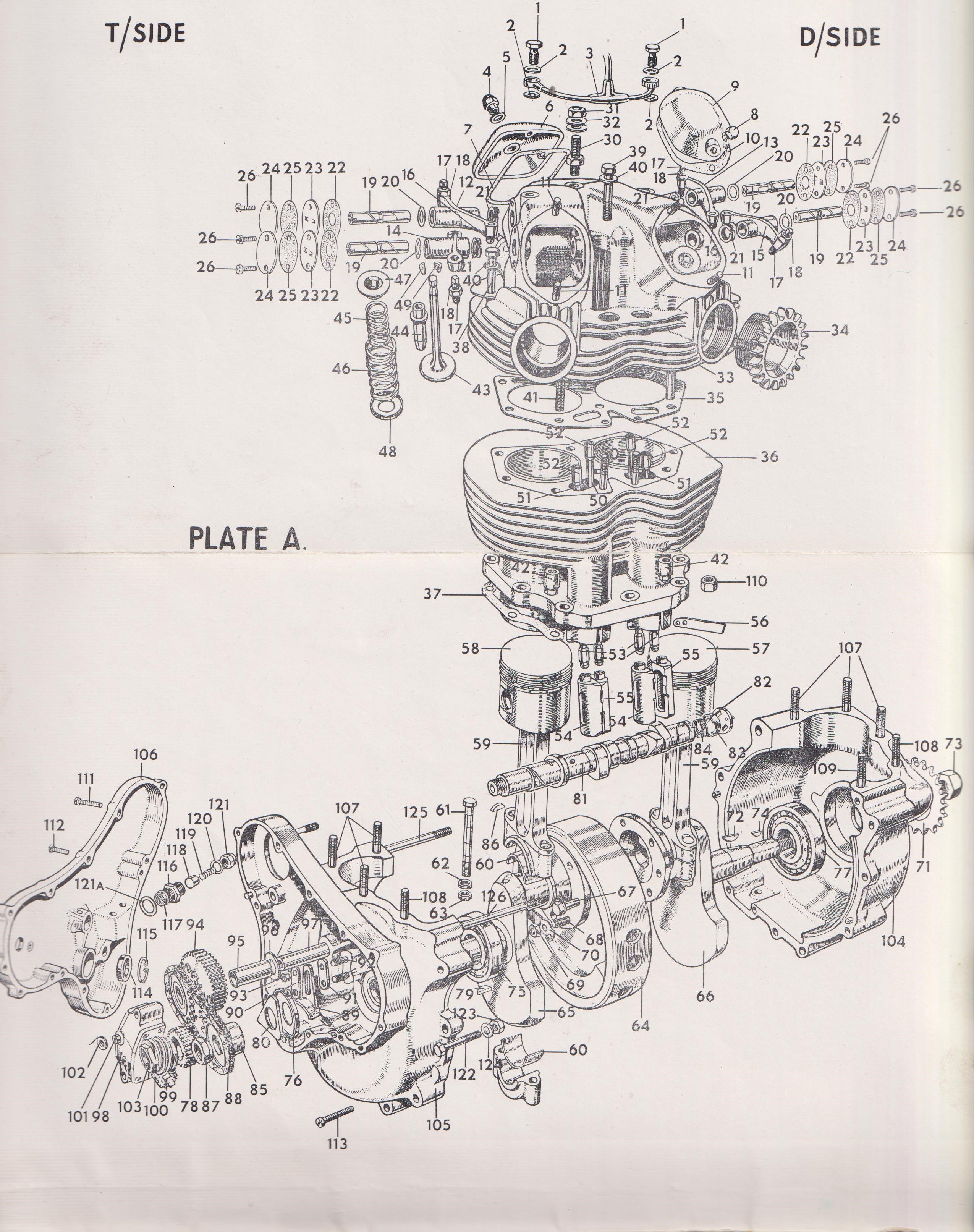

The Haynes Service books are often the butt of many jokes. Generally as a result of their poor photographs which are often nowhere near the text supporting them. However, even the Norton maintenance books have their faults. Check out the engine diagrams (650SS as below) which until 1966 never represented anything with a post 1961 cylinder head. Also this same diagram has the crankshaft bolt heads on the Timing side.

- Log in to post comments

Even better news

My 650SS has pressure fed rockers 6 start oil pump, the head comes from what the NOC calls a 650 standard (I have the crankcases but did not use them as they are not stamped SS) I fitted seals to the inlet valves to help stop smoking, plain rocker spindles and conrods with the oil hole facing outwards, with the PW3 cam supplied by the late great Mick Hemmings my bike goes really well and has covered thousands of miles.

- Log in to post comments

Ok... Thanks again for all…

Ok... Thanks again for all the information, conflicting or otherwise :-)

I think I now have a handle on what I need to do. Basically, the major point is that my early crankcases could be problematic with a 6 start oil pump. I have now sourced a set of 3 start pump gears. They will be fitted to the oil pump / crankshaft after I've made a "puller" to remove the 6 start gear from the pump shaft. I will use scrolled rocker spindles and take the oil feed to them from the oil tank return union. That just leaves one thing... The connecting rods. It very much looks like I'm going to have to remove the bottom end from the frame, split the cases again and either use the old pattern connecting rods or swap the bearing shells around to effectively block off the oil drillway in the later rods.

So be it... Make it so, Spock

- Log in to post comments

It is not difficult to open…

It is not difficult to open out the oil feed drillings in the crankcase to 5/16”. I did exactly that on my Atlas case. Once thus modified it means you could use either 3 or 6 start gears. the only thing to be careful about is to ensure that the drillings are thoroughly flushed, but that’s just common sense.

With the higher speed pump, there is nothing to stop you from utilising the lower pressure scavenge return for valve gear lubrication, and you would not have to dismantle your bottom end to block the con-rod drillings.

Another option for you at least.

Andy

- Log in to post comments

My single carb 650SS engine…

My single carb 650SS engine has the big oil pump with six-start gears, plain rocker spindles and the pressure oil feed, it also has a needle valve in the rocker oil feed pipe, so that I can adjust the oil feed rate, without this it over-oiled dramatically and I got a lot of comments about popes and coal burners.

- Log in to post comments

Thanks guys... It's all done…

Thanks guys... It's all done now. As far as I know, the engine is as it would have been when it left the factory in '63... Original unmodified crankcase, 3 start oil pump, scrolled rocker spindles, undrilled con-rods and rocker oil feed from the oil tank return line.

- Log in to post comments

Regarding Phil's comment…

Regarding Phil's comment about the time taken for for oil to reach all the valve gear with the original, early, low pressure system, I always do what I was told to do with Norton singles, on the first start-up of the day, take off the oil-tank cap, and stick your (gloved) finger over the oil return for 20 seconds or so, this forces a good slug of oil up into the rocker gear, and once so primed it will manage very well on its own after that.

- Log in to post comments

Yes, Niall... I agree…

Yes, Niall... I agree. Although the rockers will be assembled with Permatex "UltraSlick" engine assembly lubricant, I will still do as you say. I've used that method before as both my '71 Bonneville and '68 Tiger 90 use the tank return to feed the rockers.

- Log in to post comments

Inline Valves

A useful addition to the low pressure rocker feed would be a one-way valve in the oil line to the rockers. When the oil pump gets worn Gravity will often beat the struggle the pump has of trying to get oil up to the cylinder head. Instead it takes the escape route of heading off to the oil tank which is only half the height.

On my 1962 Dominator 650, this rocker oil feed issue was very noticeable through the replacement plastic tubing feed to the head. John Hudson's suggested cure was to put a washer shaped restrictor inside the oil tank return fitting. I found an easier option using a chunk of 1/4" internal bore rubber tubing that was split along one side. This was fitted inside the oil tank over the return pipe so that it covered the return hole. On cold starts this did the same job as Niall's finger and helped to force oil to the rockers. Once the oil got hot, the rubber softened and allowed more oil back to the tank.

- Log in to post comments

"I found an easier option…

"I found an easier option using a chunk of 1/4" internal bore rubber tubing that was split along one side. This was fitted inside the oil tank over the return pipe so that it covered the return hole. On cold starts this did the same job as Niall's finger and helped to force oil to the rockers. Once the oil got hot, the rubber softened and allowed more oil back to the tank."

That's an interesting idea, Phillip... One I might pursue. At the moment, my oil tank is away at my local body shop being prepared and painted, but from memory, the return pipe didn't look that easy to get at.

- Log in to post comments

CON ROD OIL HOLE ORIENTATION

Dear Members,

I acquired my 1965 650SS in 1974 with a wrecked engine caused by a snapped drive side con rod. I restored the whole machine over the following eighteen months utilising the Haynes manual because I had no other reference material.

I bought two 650SS crankcase halves and two con rods on the second hand market. I followed implicitly the instructions written by Haynes. The replacement con rods did have the small holes in them.

I have ridden the bike ever since then with a mileage of about 800 miles per annum and have had the cylinder head off three times but never delved into the crankcase.

I ride fairly moderately and have hardly ever revved the engine over 4500rpm. I fairly occasionally put my finger over the oil tank return when finishing a ride out.

I have no intention of dismantling the engine to reverse the oil holes position. If it ain’t broke, don’t fix it.

Regards,

Anthony Bolton

- Log in to post comments

The S oil pump had more…

The S oil pump had more capacity than the standard pump. It was introduced to all he UK models wearing the SS derivative in 1960/61. It was also fitted first to all Atlas, 650 Standard and De-Luxe models. There is an S stamped into the front of the pump's casting to identify it. The S disappeared when the standard pumps ceased production around 1964. The scavenge gears in the pump are bigger than the standard pumps. Cheers, Howard

- Log in to post comments

Commando 850 gearbox parts

Hi I'm looking for gearbox parts for my 850 74 on commando The main parts gear change ratchet 06 5212 and pawl carrier 06 5216 if anybody has any of these parts for sale please let me know. Thanks

- Log in to post comments

Hello John - You don't specify what year your crankcases were from - the early and late ones had different oil way sizes and breather passages. When you fit plain rocker spindles make sure that the flats on the spindles face away from each other. Cheers, howard