Today I dismantled the front end of my 1959 Jubilee to have a look at the front brake and fork bushings and oil seals.

After struggling with the left side axle sleeve nut using heat an penetrating oil to loosen it I finally managed to get the fork off the bike and in pieces.

One of the oil seals was already broken .

I have new ones.

I guess the bushings are soldered on the fork legs.

I have to slide the new oil seals over these bushings without destroying them.

There are these threads on the fork sliders. Do the new oil seals screw on to the threads?

There is no corresponding thread on the inside of the oil seal´s metal collar.

I also need new stearing bearing cups because the old ones show marks from the bearing balls.

Hi Ulrich, think you’ll find…

- Log in to post comments

I find a wrap of insulating tape....

I find a wrap of insulating tape ("electrician's" tape) covered with a smear of silicone grease over the bush lips helps the seals pass over the bushes without cutting the seal. The bushes are not really oil tight and there is so little oil in the fork legs that it is only for lubrication not damping in my opinion. Remove the tape once the seals are past the bushes!

Dennis

- Log in to post comments

Hi Uli, hope you are well, I…

Hi Uli, hope you are well, I was going to say what Bruce and Dennis have already said - I will have a similar job to do on mine in the near future.

Dan

- Log in to post comments

fork seals

So I reckon the seals go on first up over the bushings and then I fasten them on the pushed up sliders?

@ Dan, Yes I am doing well despite working on that Jubilee.,haha!

- Log in to post comments

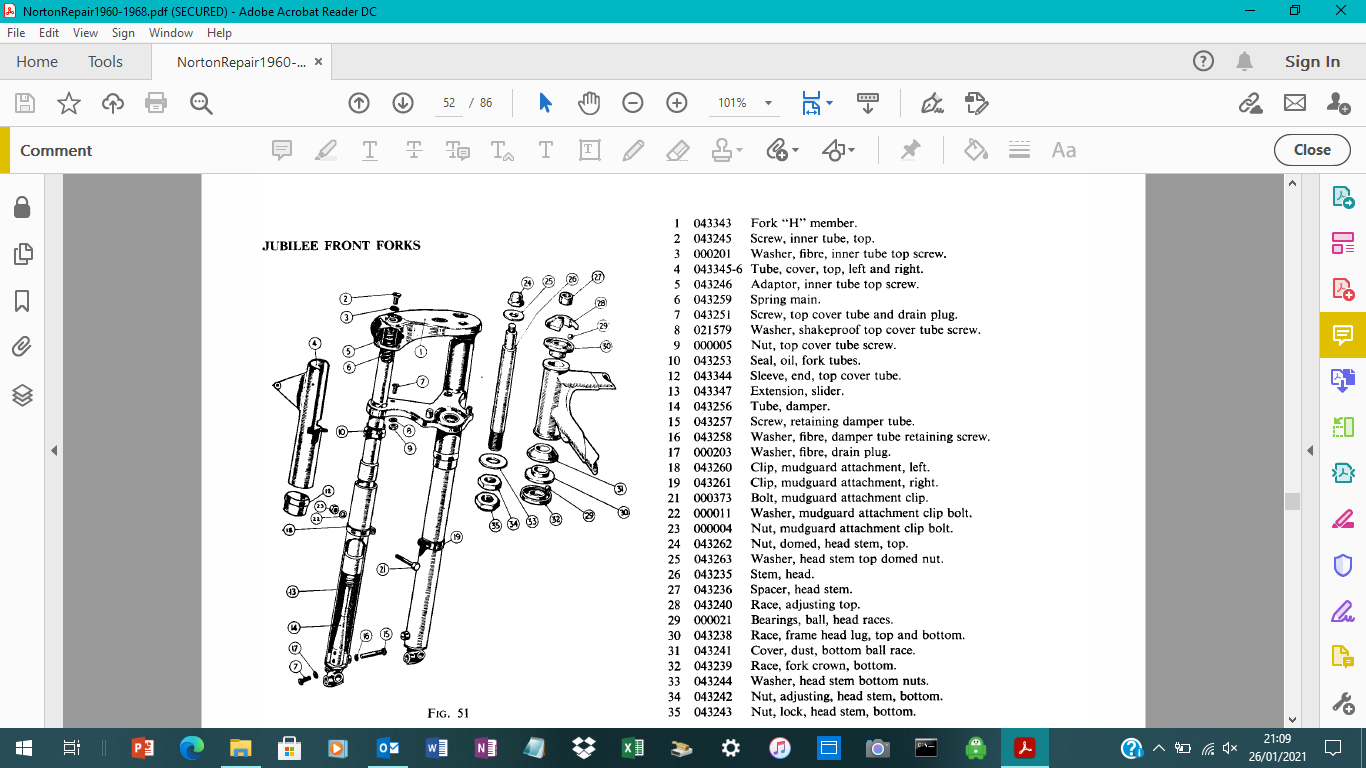

This diagram of Jubilee front forks may help.

Uli,

This diagram may help. The oil seal is item 10 and is located above both bushes. The bushes are soldered but unless they are worn enough to feel slack when you try to move the fork leg front to back when assembled they will probably be useable. The bushes on mine were scored and looked worn but there was no lateral movement when they were were cleaned and reassembled.

Dennis

- Log in to post comments

These forks..

.. which are the same as I had on my Francis Barnett - are horrible things. The best way I found was to make a partial cone from some thin flexible plastic - I used a 5 litre bottle of windscreen washer fluid - to help the seals over the bushes. As you guessed the bushes are soldered onto the stanchions which are welded to the yokes.

I found this helpful: https://majcd213norton.blogspot.com/2015/11/refurbishing-norton-jubilee-lightweight.html and it's where I got the tip.

- Log in to post comments

I think I did it my way......

Ian, the link is very helpful concerning removal and replacement of the bushes but I am not sure I agree with the method of reassembly.

If I recall correctly, I slipped the oil seal over the bushes, using electrician's tape and rubber grease to protect the seal from cutting on the bush lips. Then, I put the fork legs back together and then I worked the seal into the fork leg. In the article, it appears that he pushed the bush past the seal already installed in the fork leg. I am not saying that won't work but I did it my way.

I have not used Loctite for securing bushes but it looks promising.

Dennis

- Log in to post comments

It's a while Dennis..

.. but I seem to remember that the seals were a very tight fit on the fork lowers so I think(!) I did it the same way as the chap in the link. In restrospect yours may well be a better way. But I still don't like those forks!

- Log in to post comments

Jubilee forks

Well, I am starting to dislike the forks also.

My Navigator has the Roadholder forks which I am more familiar with.

Thanks for the tips!

I am waiting for a delivery from the NOC shop with new bearing cups and bearing balls.

Will report when assembling the forks.

- Log in to post comments

Fork Slugde Trap?

I dismantled the fork further an found the "sludge trap" but no oil!

No wonder with thoes broken fork seals. See above!

The damper bottom and it´s housing was full of crud but only a frew drops of oil came out of the slider. According to the manual 75cc of SAE 20 fork oil go into each leg.

I cleaned the sliders an dampers with brake cleaner and a round brush taped to a rod to get into the bottom of the slider. I also cleaned the groves holding the fork seals with a wire brush. The sliders look clean on the insede, no corrosion.

Now I am waiting for the new cups an balls for the steering bearings.

I want to assemble the bearings and the upper part of the foork first and slide on the loweer parts.

I think aligning the upper part and the bearing cups etc.is easier this way with less weight.

- Log in to post comments

I had a dreadful time...

... cleaning the muck out of mine. I assembled the forks first then fitted to the frame but as mine was completely in parts I held the frame upside down in a workmate which made things easier. I wasn't impressed by the method of "adjusting" the steering head bearings either.

- Log in to post comments

I roped in my wife to help with the steering head bearings..

I roped in my wife to help with the steering head bearings and she learned some new words from me!

I suggest you put down an old sheet to catch the ball bearings that drop out so you can see them more easily. Watch out for those that fall inside the steering head tube but do not fall out the bottom. If you are one or two short at the end look in the tube!!

Dennis

- Log in to post comments

Hi Ulrich, think you’ll find they’re not actually “threads” but concentric grooves that are used to grip the inner face of the seals - careful manoeuvring will get the seal lips over the soldered bushes, lots of grease helps!

Bruce