I am restoring a 1972 commando. The bike has been in storage for over 30 years. The disc is rusty. Is it a) safe b) possible to have the disc restored, possibly by machining?

Take a sander to it.

- Log in to post comments

I have had mine refaced by a…

I have had mine refaced by a local engineering company for £20. Until I get out and ride it I don’t know if I’m keen on their job tbh, and I was considering buying new, they aren’t all that expensive and I’m keen on stopping.

- Log in to post comments

Reconditioning commando discs

Answering your question

A. is it safe? To recondition it yes,

B. Yes the disc can be restored by machining. Usually i grind them.

The commando was one of the first bikes to have a disc brake and to keep them looking pretty they hard chromed the disc. This wears off unevenly after prolonged use and can cause numerous problems like pulsing lever and rapid wear of pads etc

Just using a sander on the disc carries the danger that it will be easy to go too far and create a hollow on the disc, doesn't have to be deep, a thou or two and you will have a pulsing front brake.

Better to scrape the rust off if grinding isn't required. Less chance of digging a hole.

- Log in to post comments

Even if the Brake appears to…

Even if the Brake appears to work fine with pitted discs at some time when under really heavy continuos use (decending a mountain) the brake pad will overheat and deteriorate or vapourise any moisture in the cylinder and cause brake failure. The pitting slows heat transfer from pad to disc and the cooling ability of the disc is lost. Learnt this the hard way in the Swiss Alps.

- Log in to post comments

Robert! Surely the moral there is to

Change your brake fluid more regularly! There shouldn't be any moisture in it to vapourise!

Probably a sucking egg thing, but the lesson is one of never being on the brakes continuously but letting engine braking do most of the job. Brake to a slower than you need to, then let engine braking take over and allow your brakes to cool as your speed picks up again. Then a short hard braking to bring speed down again. Repeat this until you are at the bottom.

That is what I was taught and it has worked for me on all vehicles I've driven in the mountains.

George.

- Log in to post comments

George,My brake fluid was…

George,My brake fluid was changed every year after the first issue,and I was always the slowest vehicle going down due to using low gears ,Often being passed by HGV,s with their brakes on fire. on very dangerous roads . Only left the problem behind when new Discs fitted. I drove over the High Alps every year ,for decades. Drivers are now tought NOT to use gears to slow down. I have always used the gears ,that's why the discs get rusty!!.

- Log in to post comments

Hi, Strange this thing…

Hi,

Strange this thing about not using engine braking?!

I always use the engine, particularly if the roads are the slightest bit slippery - its more controlled.

I guess it might be the thing to do with ABS? I don't know! Riding my old Ariel with drum brakes it stops well as long as I'm in the right gear for the speed and further more with the clutch engaged; otherwise relying on brake alone is not good idea especially since they fade if stopping from speed.

Just my thoughts and if I stand to be corrected that's fine as long as the argument is logical.

Keith

- Log in to post comments

Restoring brake disc.

Getting back to the restoration of the disc, if it's not pitted in any way you could try electrolysis. I'm sure there is advise within the forums on how to carry out this method of de-rusting, if not it'll be on U tube. Chrome discs were pretty useless anyway and they were lethal in wet weather.

- Log in to post comments

If the disc isn't pitted…

If the disc isn't pitted there is no reason to use electrolysis and to advise someone to try this without actually sounding like you have done it yourself is not very responsible at all. Electrolysis will de rust steel but with the likes of a disc its the soundness of the underlying metal that is paramount and electrolyised steel can have loads of stress raisers. (microscopic holes for want of a better word)

How electrolysis works on a cast iron disc i have no idea either and i have no desire to try

You could end up with at best a disc that has a question mark over its integrity and at worst a disc that fails catastrophically

- Log in to post comments

Thirty odd years ago...

I was two up, with a friend, fully loaded with camping gear on a GT500 two stroke Suzuki descending a mountain road in central France, heading for the Bol'Dor at the Paul Ricard circuit. Halfway down I realised that the brake lever was slowly getting closer to the handle bars! Deciding to stop at the first opportunity, i braked harder and juddered to a stop at the next layby. My friend who was admiring the scenery immediately asked why have we stopped? My reply was ' if we don't stop now we wont stop at the bottom, Look!' and i pointed to the brake lever that was a quarter of an inch from the handle bar. I still had the brake applied as we had stopped on the still inclined roadside. 'Jesus' was his reply!

Half an hour later when the thing had cooled down (making cracking and tinkling noises) we set off again. Along with other escapades that holiday was ace!

- Log in to post comments

I had to use bottles of cold…

I had to use bottles of cold beer to cool the calipers down. Sacre bleu!!

- Log in to post comments

Waste of cold beer?

What a waste of cold beer.....

Next time drink the beer and then piss on the calipers.........

- Log in to post comments

By the side of the road, in…

By the side of the road, in France ,no problem,but them guntotin Swiss Cops are not so cool about it.

- Log in to post comments

No Swiss cops near the Bol D…

No Swiss cops near the Bol D’or. But watch out for the ones that nicked me on the way down in ‘99 on my Blackbird.

- Log in to post comments

Rusty disc.

The original question on this thread concerned the feasibility of restoring a rusty disc. On the basis of some of the answers, I imagine William Hayley is wondering why he bothered.

- Log in to post comments

Do you want originality or…

Do you want originality or modern braking? if the latter - upgrade it!

- Log in to post comments

My Commando has been fitted…

My Commando has been fitted with an AP Lockheed master cylinder and AP Lockheed caliper. It still retains the original disc. I am thinking that a larger disc would be an improvement. Recommendations please! Sorry if I have hi-jacked the thread but it is the same subject.

- Log in to post comments

Larger disc

Hi Roger

RGM offer larger disc and a mounting plate for your caliper links below what bore size is your master cylinder?

Best regards

Katherine Scott

- Log in to post comments

Thank you Katherine and…

Thank you Katherine and others who have taken the trouble to reply to my query, I have ordered an RGM disc, but not the adaptor plate. I am looking to source that from elsewhere.

Regards

Roger

- Log in to post comments

I am now up and running with…

I am now up and running with the RGM 12" disc, but using the Norvil adaptor plate. I have only done a shake down run up to now, so no real evaluation of this set-up as yet.

- Log in to post comments

I have AN's 13mm m/c,…

I have AN's 13mm m/c, Venhill braided hoses, AP CP2696 caliper & RGM's 12" cast iron floating disc; some don't like the RGM mounting bracket required to raise the caliper (I don't find it an issue) & feel safer with this braking set up (it's not as good as my Guzzi, but way better than the original set up)

Other options are available, & I'm sure other posts will follow ;-)

- Log in to post comments

Hi, Excuse me asking, please…

Hi,

Excuse me asking, please, but who are AP?

Thanks,

Keith

- Log in to post comments

Keith, AP are Automotive…

Keith,

AP are Automotive Products who make Lockheed brake systems

- Log in to post comments

Original question

William Hayley

As I understand it the preferred method to recondition a disk is to have it 'Blanchard' ground, aka rotary surface grinding.

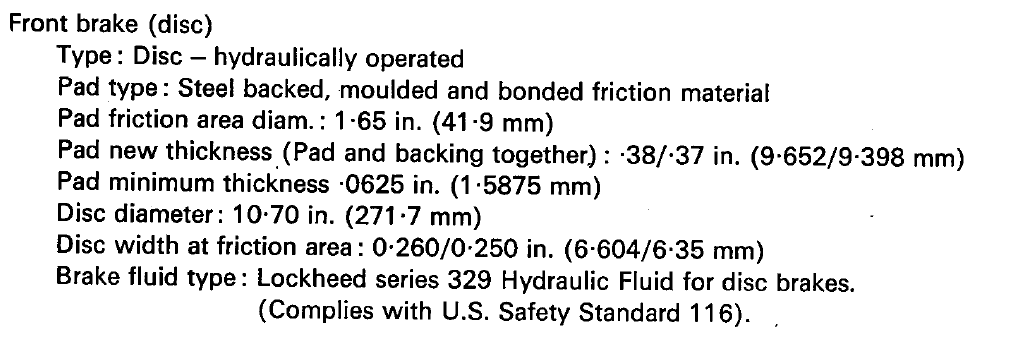

Page 12 of the workshop manual (065146) has the following:

So I assume 0.25" is the minimum disc thickness.

Regards, Andy

- Log in to post comments

Take a sander to it.