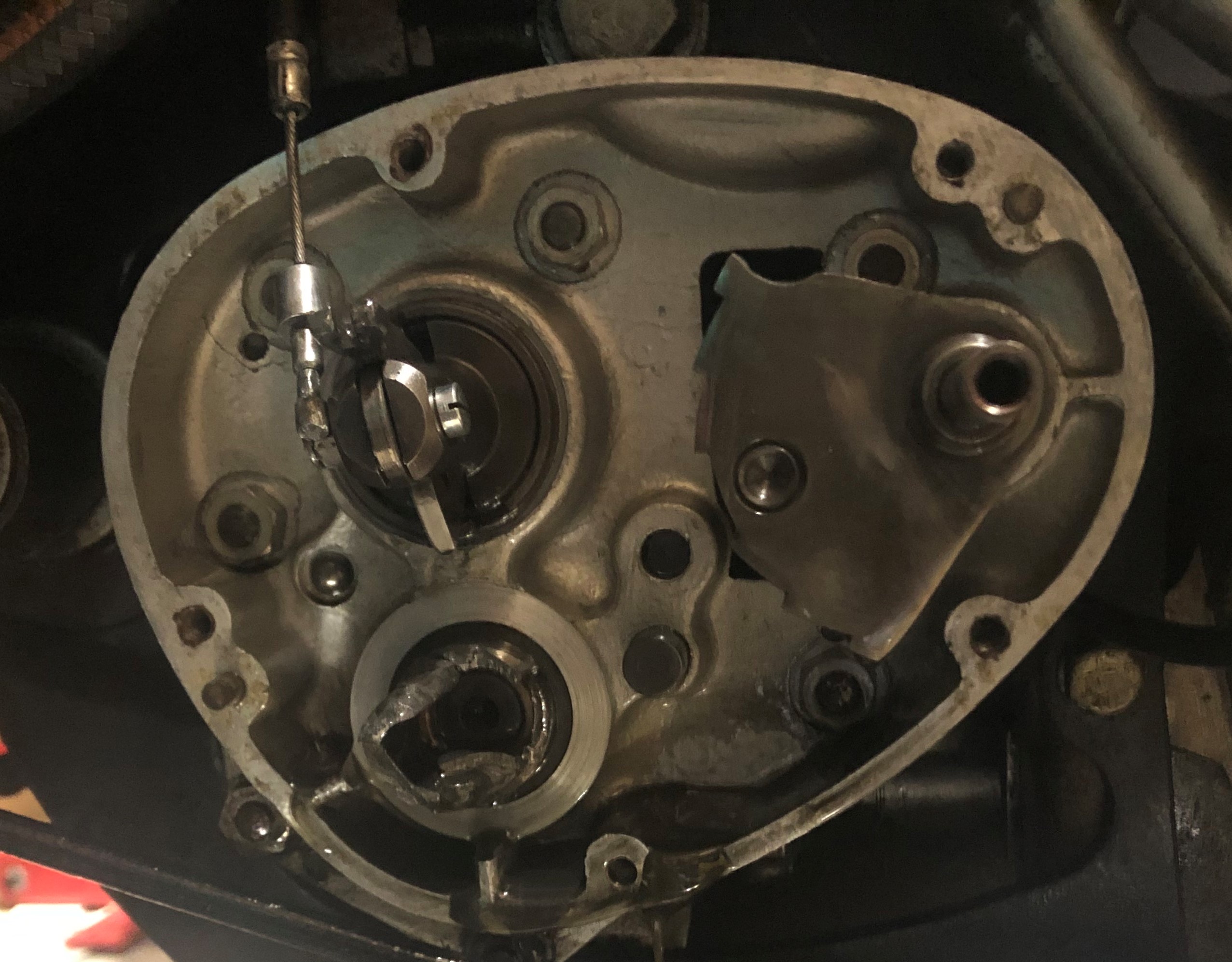

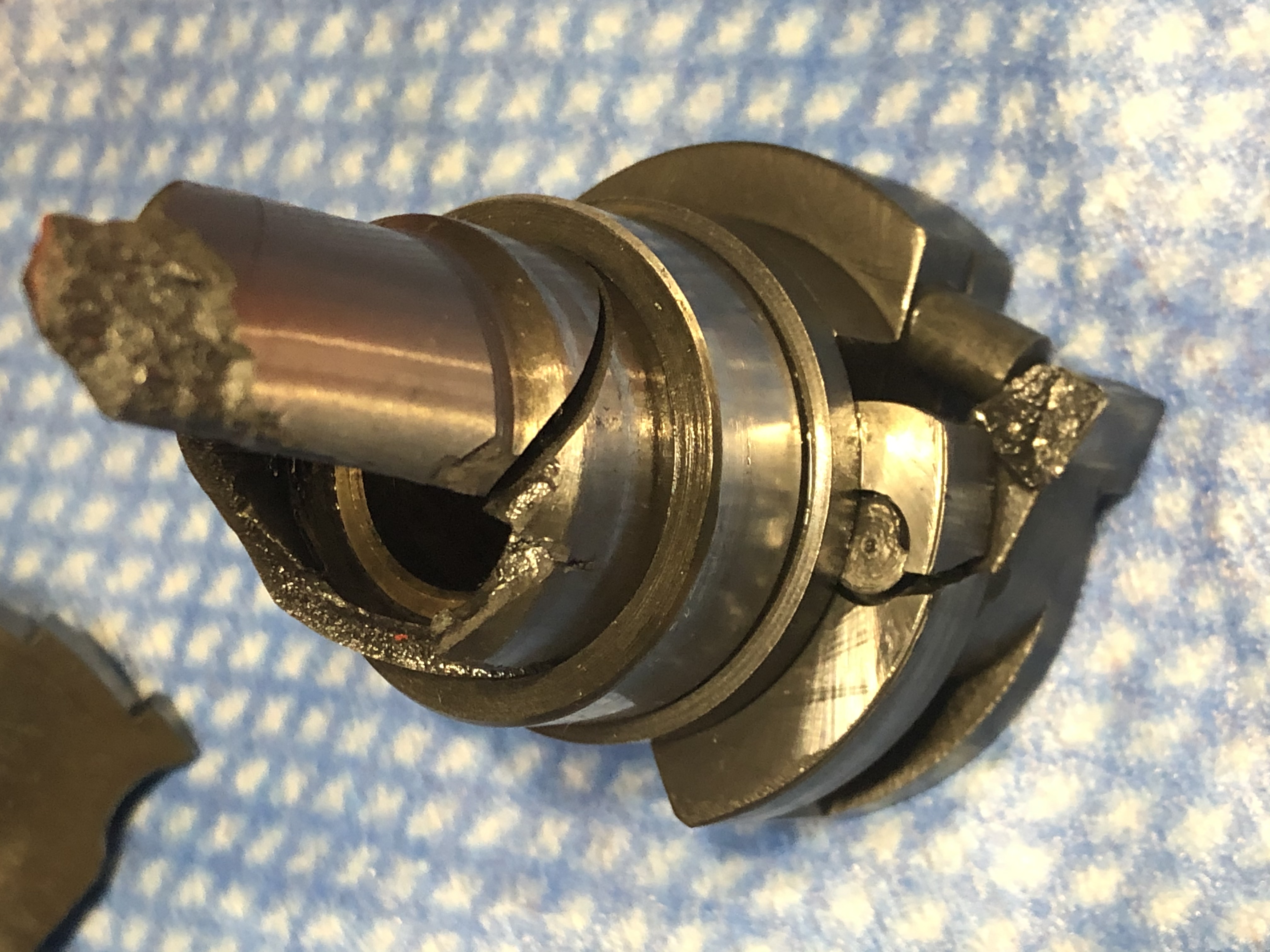

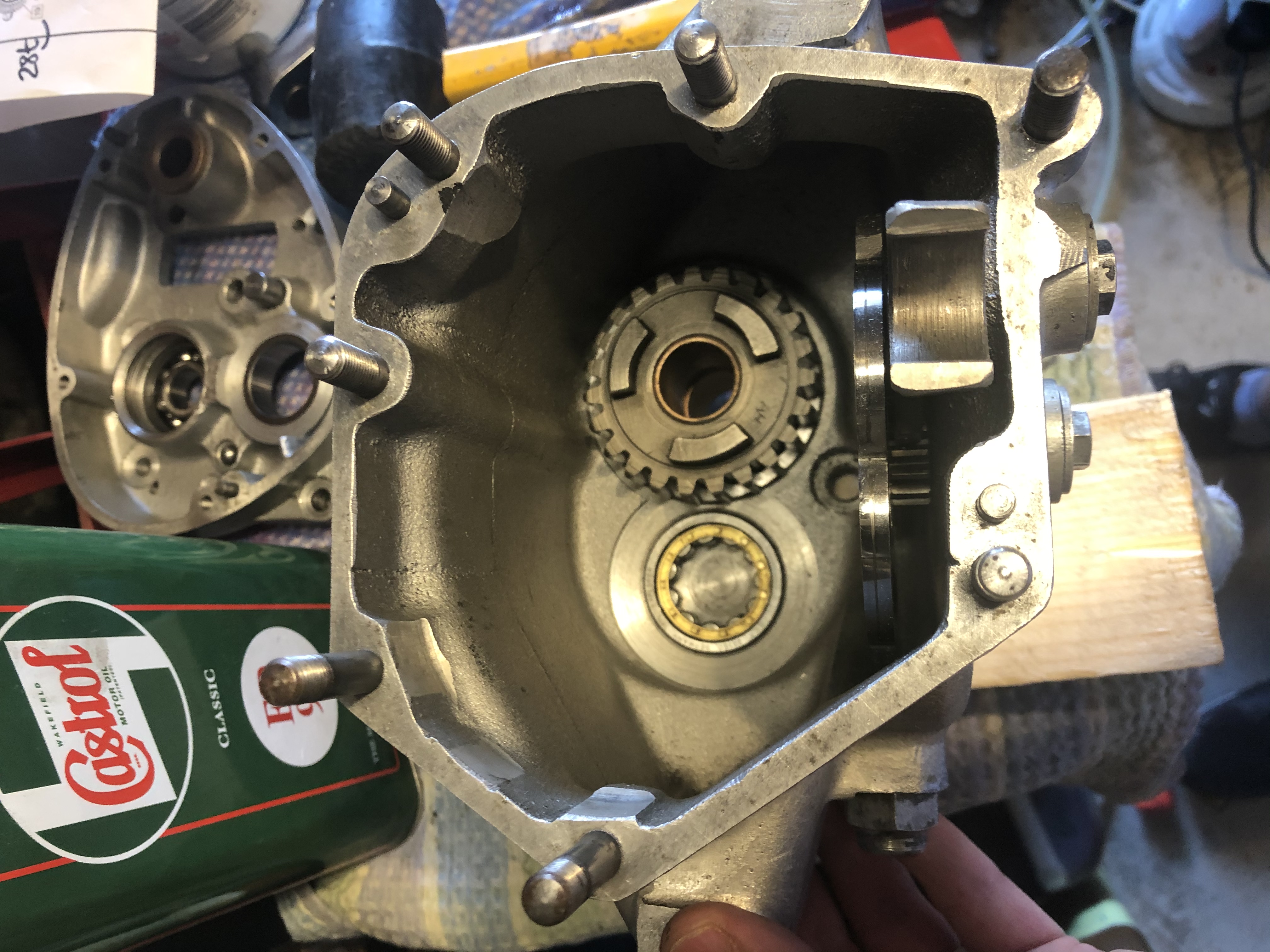

Just installed my shiny new exhuast system on my Roadster. Thought I'd give her a kick and listen to the tone. On the second kick I heard a crunching sound, definitely metal to metal. This is what I found. Looks like the kick starter shaft failed at the spring hole and caused a collapse which also wrecked the outer cover bearing and boss.

Is this something that happens? What else should I consider when I am repairing this mess?

Pattern?

TBH I have limited history of the bike. It is Jan ‘72 but has a combat engine with 14k miles and was originally exported to the USA with the fibreglass tank etc. Last year it was brought home as a none runner, according to plates last registered in ‘79 for road use. Apart from louder exhaust she was standard. So assuming she is standard. Oh and the kickstarter pedal was a dog to get off, maybe didn’t help.

- Log in to post comments

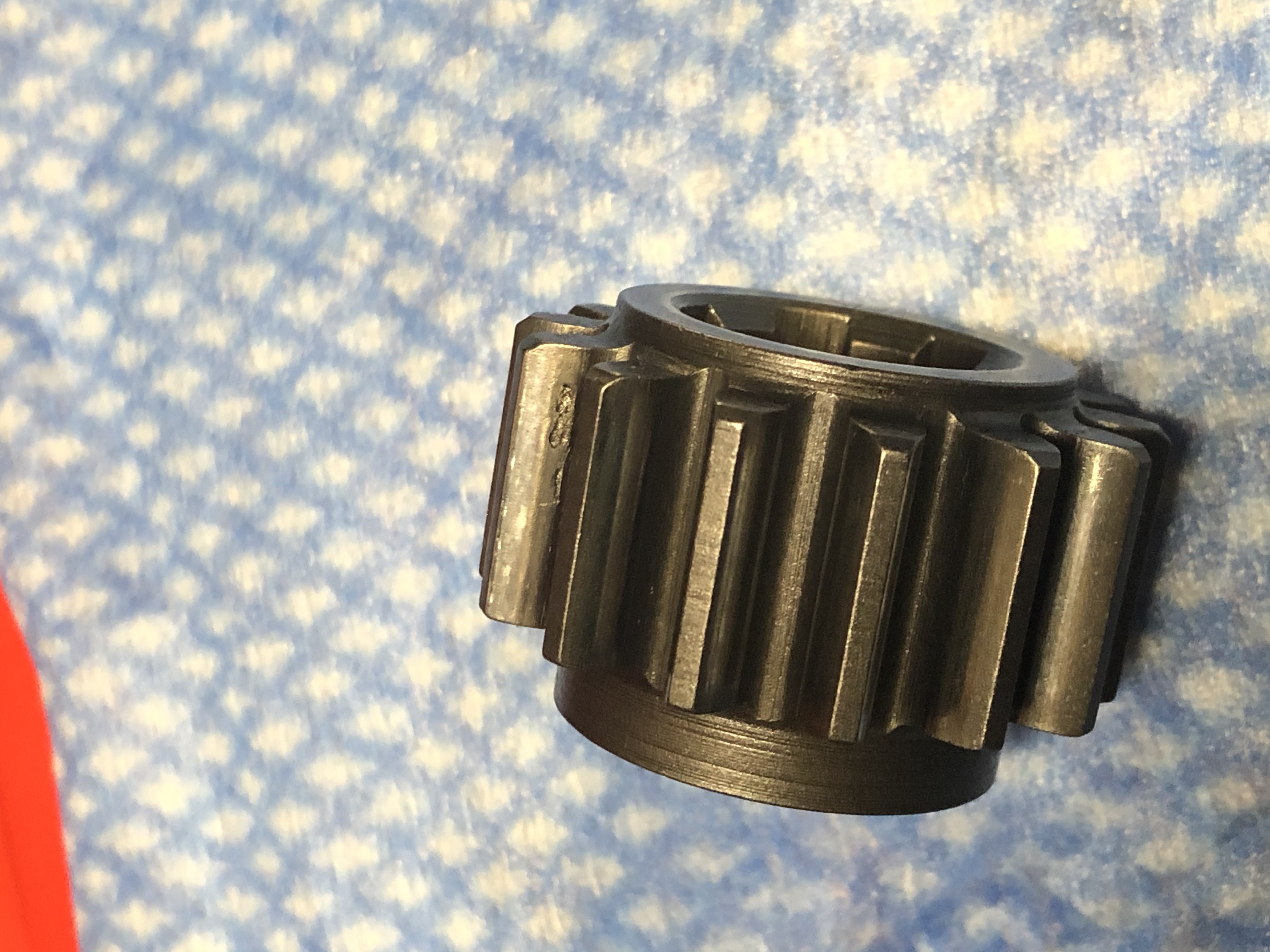

Not an OE part

Looks like its been made from steel coloured cheese.

Buying bikes as non runners is fraught with problems like this. It really is the luck of the draw. Unknown service history... For peace of mind, I would be tempted to do a full engine and gearbox strip to check that there isn't anything else waiting to let go. You really don't want a seizure, gearbox lockup etc when travelling at speed.

- Log in to post comments

Not the first I have seen…

Not the first I have seen them fail like this. Another batch of these was seen earlier this year, it seems they run in a 3 year cycle, I get the odd one sent to me. Not sure where they are coming from, but have many deficiencies which easily gives them away. Just from looking at the photo I can see it is fake, not even a good copy. Most crack in the pawl area.

- Log in to post comments

suppliers

there is a lot of history about sub-standard parts on here and accessnorton. Usually, it comes down to buying from very few reputable sources, and even then , there are personal preferences over particular items.

In general, it seems there are more badly made/specced items around on other websites, which are cheaper to buy initially.......

- Log in to post comments

There is

Despite knowing the faults, we no longer highlight them as this effectively gives away how to make them. Not one company in the world lets their competitors know how to make items correctly, not even if they are deadly, as one NOC owner found out a couple of years ago.

I even watched the trail of them being made after our stock was slated for not being correct. It was not even a challenging item to manufacture, had they also tested a part from any of the leading global suppliers of these parts that are used on other motorcycles they would have spotted the error they could have avoided.

- Log in to post comments

Truth must be known!

Ashley:

So, rather that letting the Norton parts buying public know that the various suppliers are putting forward some sub-standard parts, you would rather let the public suffer the consequences?

Or, if you put forward a notification about a sub-standard part being marketed, are you afraid of being sued? The truth of your statements will always be a justification, right?

Mike

- Log in to post comments

Ethical dilemmas

I sympathise with Ashley's, or rather AN's, predicament.

On the one hand, keep silent about known defects in competitors' products.

On the other, perform a public service at the cost of inviting an action for defamation that would be expensive even if eventually defended successfully.

If I was running a business I fear I know which option I would choose.

- Log in to post comments

Sub-Standard Parts.

The public knows that sub-standard parts are being supplied and they continue to buy them. Forty years ago, we had no choice. NVT had let us down. Wassell and Harris were supplying goods that I wouldn't have used had there been any choice and a dealer in the midlands was punting out reject bin scrap. Plus ça change...

Even in the pre-internet closed market 1970s, at a time when local authority Trading standards still existed in more than name only, it proved impossible to protect idiots against themselves.

The buyer has to do his own research, and I know who I trust.

- Log in to post comments

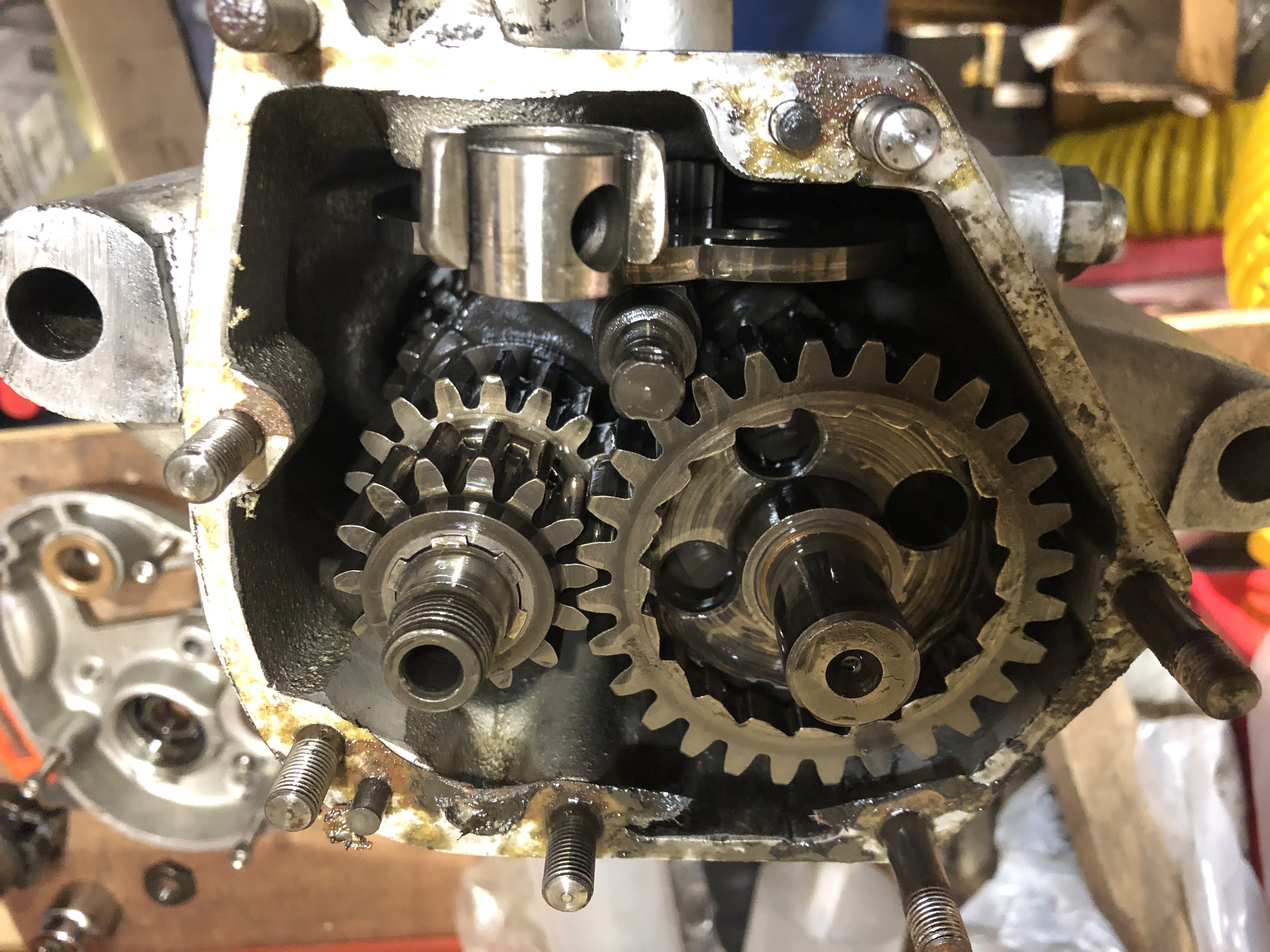

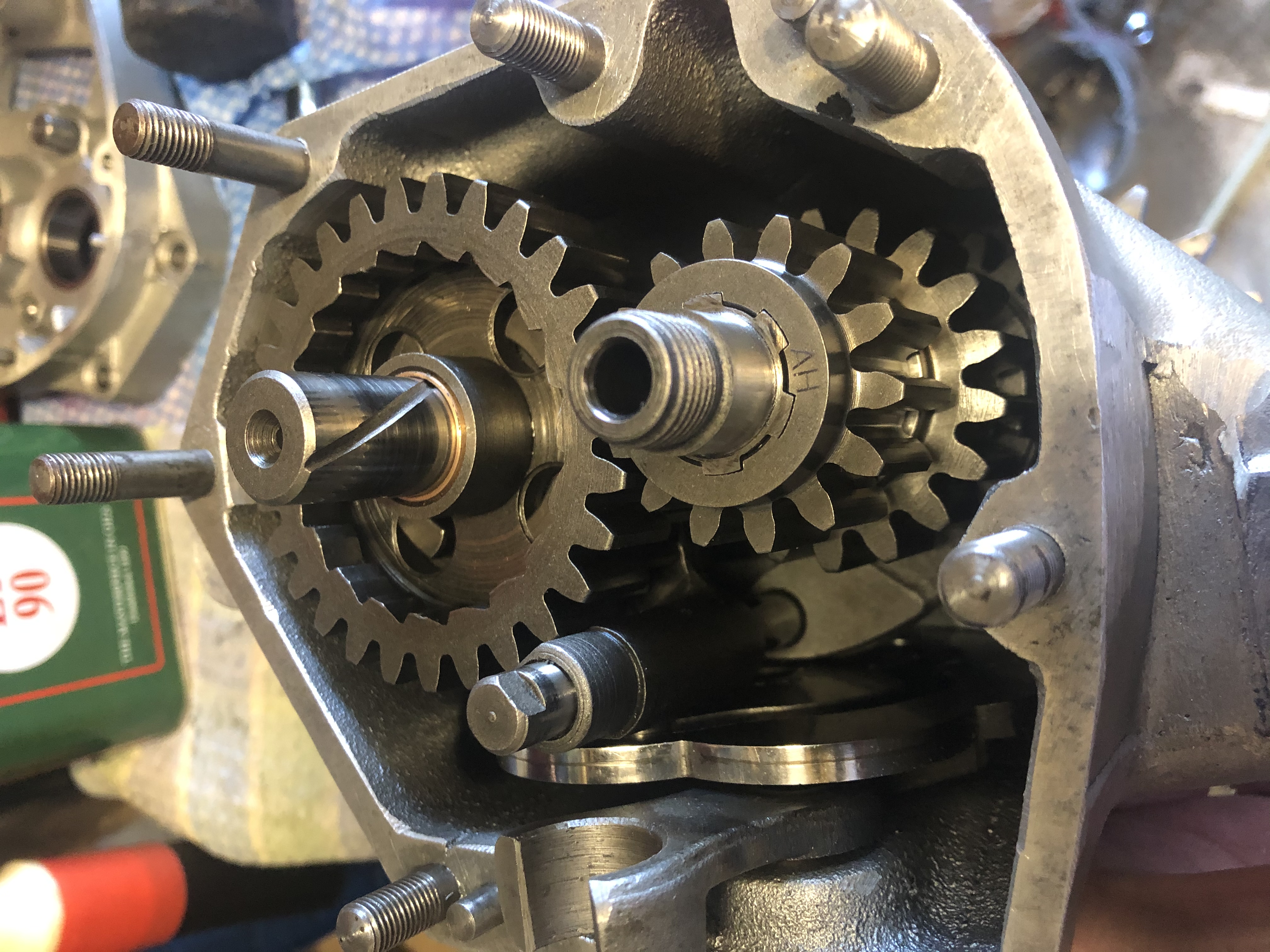

Found some time to continue the tear down

I managed to split the gearbox further, looking at the state on the gaskets and what it took to break the seal I reckon everything was still OE. Generally speaking the internals are in good shape apart from 1st and 2nd gear where there is some pitting where the teeth mesh, I will replace these. The inner cover is also damaged from the kick start shaft failure, I am reluctant to replace circa £160+VAT just wondering if anyone has had such weld repaired and remachined/pressed insert, and if this is economically viable?

- Log in to post comments

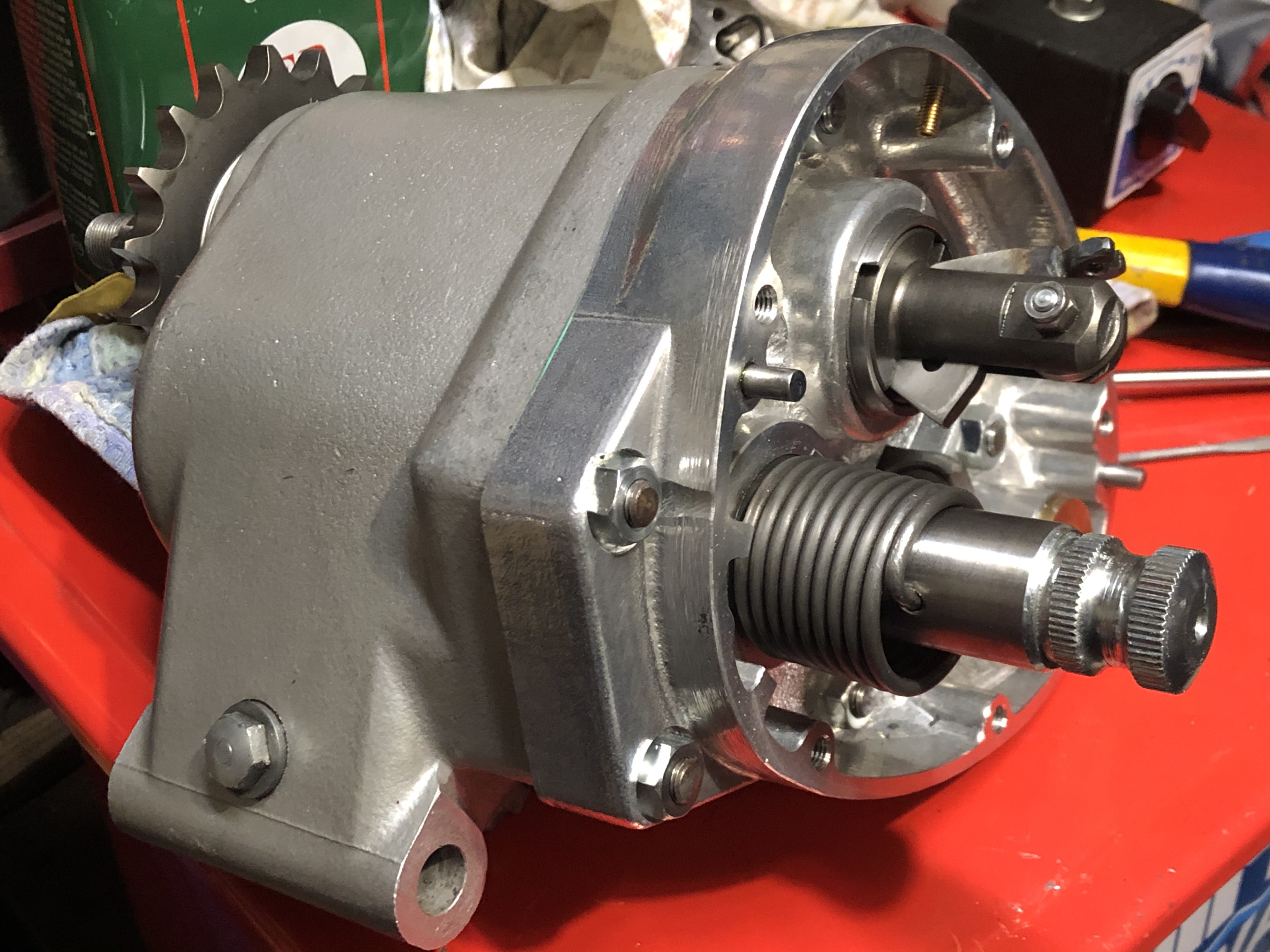

Ready to go

Finally rebuilt the gearbox. We are really fortunate that there’s so much information available to do this kind of work correctly.

Finally rebuilt the gearbox. We are really fortunate that there’s so much information available to do this kind of work correctly.

- Log in to post comments

I've never seen that with an OE shaft and the distortion to the splines is suspicious too. The only common fault I think is a crack from the stress raiser on the internal quadrant to the drilling for the pawl pivot pin but I've never known it to be fatal.

Do you know who the supplier was ?