As mentioned before one of the primary chaincase screws had a stripped thread in the crankcase. Further inspection showed that one of the others had already been fitted with a helicoil, It was sticking out from the crankcase.....

I've ground the protruding portion off with a small stone in the Dremel.

What I don't understand is why those piddly little 1/4" screws when there's plenty of meat for 5/16". Asking 4 little screws (plus the primary chain tensioner) to take the weight of the casting plus starter motor is asking a bit much I think.

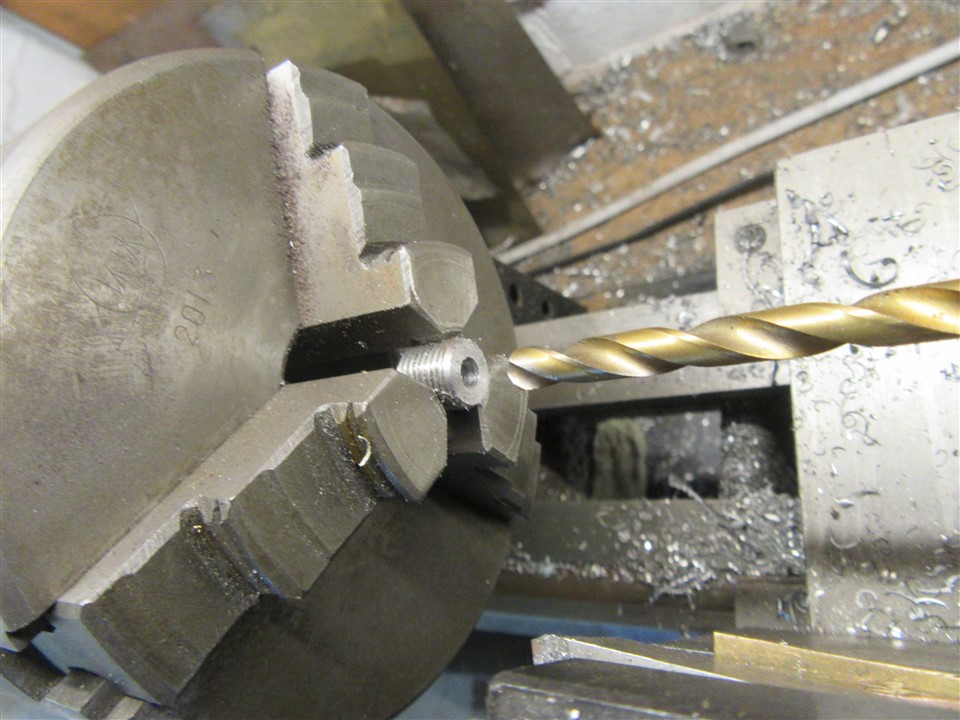

Making an insert stage 1: made from an old 3/8" Cycle thread setscrew from the scrap box. Drilling for 1/4 BSW tap:

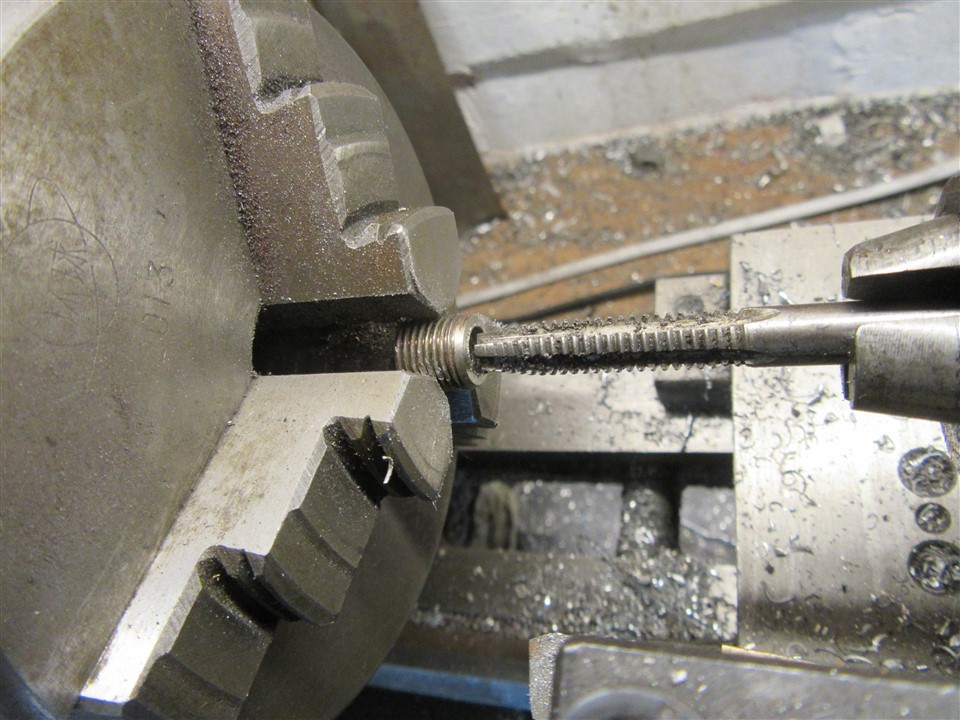

Stage 2 tapping:

Stage 3 insert loctited in place. Slightly below the surface.

Nice repair

- Log in to post comments

Thanks John.

Yes that would perhaps be more elegant. I have however sized it so that the insert bottoms out in the hole. I think it will be secure enough especially with the loctite.

In hindsight maybe I should have just opened all the holes up and tapped them 5/16" BSW although the countersunk heads may have been too big.

- Log in to post comments

Those four screws

Normally the three screws around the crankshaft drive side seal are OK. I think you have been unlucky Ian.

The fourth screw is often a problem. As you say the overhung weight of the Electra starter motor bears down on this little csk 1/4 whit screw. It must be locked in place by peening or Loctite of some sort.

The thread that it screws into is on a very weak part of the main casing. Easy for the thin wall holding this boss, to be bashed up or down when removing/installing the engine/gearbox unit.

Yes the proper studs holding the primary seal tensioner should help keep things in shape, but the early lightweights with steel chain slippers used bolts. I have even seen the studs replaced with screws on later nylon slippers. No good at all.

All this brings me to my final observation. The oil seal in the primary case must be central to the mainshaft and sleeve gear.

So I suggest you put in only the front three 1/4 screws. Check the rear oil seal is snug and equal around the sleeve gear. Then squint through the fourth hole and make sure the screw thread in the engine case is exactly behind. Corrective action with hammer and wooden block, up or down, on crankcase will get exact alignment and cure the leak in rear sprocket area so often seen in lightweights.

Works for me.

Peter

- Log in to post comments

Thanks Peter.

Waiting for a gearbox sprocket tab washer from NOC spares but when fitted I'll follow your suggestion. I have some long 1/4" BSW screws that should allow me to check alignment. As a side issue the countersinks on the inner cover aren't in great shape but the chaincase should register laterally and vertically (but not rotationally) on the crankcase register.

- Log in to post comments

I've done...

... what you suggested Peter and fortunately the tapped boss on the crankcase lines up well with the hole in the primary chaincase when all is snugged up. Unfortunately it's the only one of the three that I'd feel unhappy about taking out to 5/16" so I'll just leave well alone.

The 4mm silver steel seemed a tad bigger than the drill shank so needed a fair amount of pressure to fit. But all in there and looking good.

I do have quite severe wet sumping - I've taken the sump plug out and even after draining overnight there's still a drop every 30 seconds or so. But I'm going to leave that for the time being as I'd like to actually ride the bike before I'm too decrepit! Rather than grovelling about on the deck with the crankcase drain, I'll make a decent arrangement to drain the oil tank and do this if I leave the bike more than a week or so without running. I can't see anywhere convenient to fit a tap in the feed line as it's behind the trim panel.

When winter draws on I'll have a look at the oil pump.

- Log in to post comments

Lightweight wet sumping.

Getting a bit off topic here Ian.

Unlike some other Norton models, the full tank of oil fits into a lightweight crankcase with enough space left under pistons to fire up without fear. The crankcase pressure will be higher and that is why the drive side oil seal is peened in three places. Keep the revs low as the pump lifts the oil back into the tank.

Any oil sent out of the crankcase breather goes back to the oil tank via breather pipe.

Nothing to worry about Ian.

I lent my Navigator to a friend. Navi had been standing a while. He dutifully checked the oil level first and topped it up to full. Can confirm that the oil tank will not hold twice the recommended amount. An oily ride from Weymouth to Cambridge.

Peter

- Log in to post comments

Yes,

I remember in my Commando days making that mistake. Once done never forgotten as the neighbourhood disappeared in a cloud of blue smoke. Hence my thoughts.

I'll rely on your experience although I think when the bike's not being used for long periods I'll still drain the tank.

- Log in to post comments

Perhaps the insert should have had a head on it to help locate it in the case? I'm thinking of a very small countersunk head or a very small counterbore so the the insert has something to tighten up against?