1959 Model 50 - Rebored to + 0.040", new piston/rings, reground valves, new gaskets, meticulously assembled. Rings checked in bore - 0.005"/0.008"gap. Ring gaps staggered at 120 degrees. Compression tested before fitting the rocker box so no issues with valves and no interference from valve lifter. Definitely no leak past valves (tested by filling with petrol). RESULT - No, or very little, compression ! So, it can only be the head gasket ? Yes ?

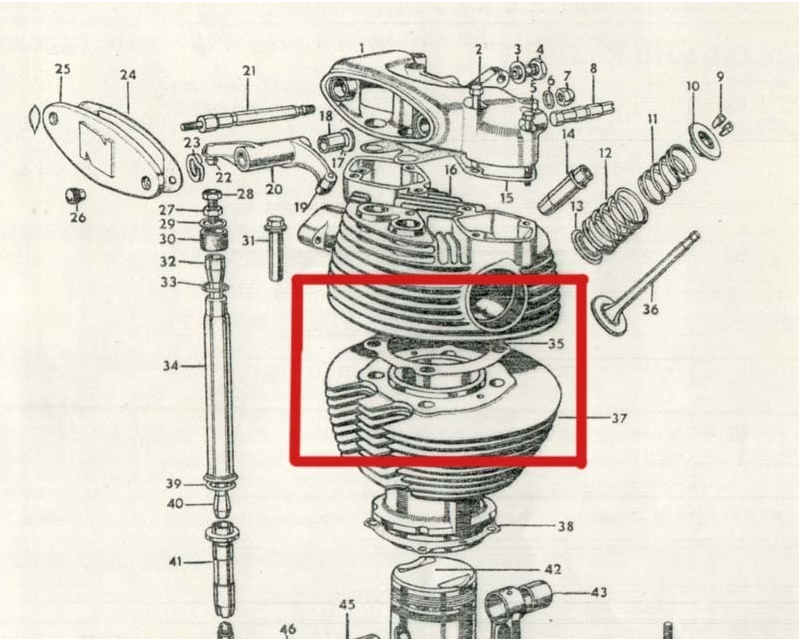

The head gasket is aluminium purchased in a kit from RGM. The top of the barrel and the surface of the head seem to be flat & true. My attention has turned to the spigot. The question is, is the seal made with the spigot, with the flat surfaces of the head and gasket, or both together ? Although I've not been able to measure it precisely it appears that the spigot on the barrel is slightly longer than the depth of the groove in the head into which it fits.

I've seen forum conversation about lapping the the head to the barrel and dispensing with the gasket - surely this isn't necessary ? It was certainly assembled with a gasket before I stripped it down and it had compression then. Why would a rebore have altered this ?

Where do I go from here ?

Happy New Year,

Mike

I don't know about the…

- Log in to post comments

head gaskets

i have had new alloy head gaskets blown on my es2+ mod 19 engines // where the 4-stud- holes are made for the Head-sleeve nut size are approx 2mm + .larger than the stud ..they don't need to be that size as the Sleeve-Nut doesn't go through the gasket.. these gaskets i bought must be made by Monkeys .. i have had to hand make a Copper-gasket to suit.. do you know where i can get copper -head-gaskets made.. Tommy

- Log in to post comments

After checking mechanical obstructions...

...as per Robert. Squirt a few oz of engine oil in the plug hole and kick. If it still the same . Check out your clutch...

maybe....

roll on warmer garage !

Jon

- Log in to post comments

No compression.

Hi Mike,

Is it possible that one of the pushrods tightened up when you adjusted them after the rebuild and it is holding a valve off it's seat ? Or perhaps a valve spring cap is fouling the rocker box which will leave a witness mark. It might be best to remove the rocker and check the compression then. If there is none with the box removed, this would mean the rings are the most likely reason. When you gapped them did you sight them in the barrel into a bright light to see how concentric the fit was in the bore ? The gap measurements sound too tight for the compression rings, 12 thou for the top and 10 for the second are about right but 8 is correct for the oil ring.

The head gasket was a poor short-cut to make production cheaper and quicker. The spigot and head recess were originally the same size at 0.25" and fitting the aluminium gasket spoils this measurement and the double joint seal. No OHC engines were fitted with head gaskets and it is best practice not to use them on OHV singles and double lap the faces instead. It is possible the problem is the gasket as these are made of soft aluminium and if the head is over tightened this can be distorted or split.

- Log in to post comments

M50 Compression - Thanks and more ..............

I do appreciate the responses but it seems that many did not read carefully my stated problem ! The rocker box is NOT fitted, hence any issues with rockers or the valve lifter mechanism interfering with the valves are obviated.

It must be a failure of the seal between the barrel and the head. I take the point made by Richard that the fitting of a gasket spoils the possibility of the spigot sealing and thus a double joint seal is impossible with the gasket fitted. So should I just attempt to go for the single seal afforded by the gasket or should I lap the head and barrel, spigot and all, and go for a no gasket seal ?

If the aluminium gasket isn't doing the job, are there any alternative agskets out there that may do the job better ?

Thanks,

Mike

- Log in to post comments

model 50 rebuilt no compression

They don't appear to have a lot of compression until the new rings bed in try running it for a while.

- Log in to post comments

compression

Is the new gasket thinner than old one, and spigot holding it apart?

I am building a short stroke model 50 with 87mm piston, and the racer who is advising me said to use the new liner spigot as the seal, and leave an air gap where gasket would be (15 thou or so). My machinist has ground the surfaces together, except with mine, the spigot fits into the new edge of the enlarged head recess, so should be a good seal. ( oil drain is sorted with small O rings to fill gasket gap, in barrel recesses). Then 33 ft lbs for head bolts. Jan.

- Log in to post comments

Racer v Road

Jan,

The way you are doing it sounds great but it is probably a bit over the top for me. I don't have a machinist at my disposal and I am assembling a road going 'plodder', not an over bored racing machine. I am seeking to restore the machine to somewhere near it's optimum performance at the time of manufacture - 1959.

All the best,

Mike

- Log in to post comments

Timeline analysis...

Mike; do I understand from your first paragraph that you conducted a successful static compression test without the rockers installed suggesting that the cylinder was sealed initially but on completion of build it now lacks any pressure?

I would still be looking at the valve train; even a failed gasket would give some level of pressure and the leak over would be evident audibly or via traces if residue emitted at the joint.

The detail you have gone to suggests it should be right but take Richards advise and retest with the rockers off before disassembly of the head / barrel.

Cheers

Jon

- Log in to post comments

The seal should be on the…

The seal should be on the spigot, from memory the old George Cohen website used to recommend that the spigot be 2 thou taller than the head recess.

- Log in to post comments

How did

You manage a compression test without the rockers on or have I misunderstood something? Comp tests should be done at WOT too. No air going in = nothing to compress.

Moving on, it could be worth trying a 'leakdown' test if you have access to a compressor. Remove plug and pressurise the chamber (at tdc firing) and listen for leaks. 10psi is enough. A spray of soapy water around the head joint will visually tell you if the joint is good or not.

Regards, George

- Log in to post comments

Hi Mike Have you looked…

Hi Mike

Have you looked HERE at racingnorton.co.uk?

The description clearly states that an aluminium head gasket was used from 1956 - 1959, also see the picture from the 1957 parts catalogue.

- Log in to post comments

Leakdown test...

... can be tricky to hold at TDC but if the rocker cover is off then it could be done at BDC just as effectively.

- Log in to post comments

Compression leak pursued ........

I can't reply to each comment individually so I'm replying here to all who have offered advice. As seems usual, even with basic things, I am receiving conflicting views on the subject of spigot versus head gasket. I am going to concentrate on the head gasket and, if the spigot provides any assitance in elininating any leakage form the joint between the head and the barrel, then so be it.

Foolishly I was making the mistake of testing the compression without letting in air - i.e. no valve operation with rocker box off !

Advice on use of bubbles and compressed air is welcomed. I'll gave a go at that. Back to the garage - bloody cold but not much else to amuse me in these COVID times.

Many thanks,

Mike

- Log in to post comments

My M50 has one of Mike…

My M50 has one of Mike Pemberton’s 520 barrels with a reworked head and bigger carb, The bike is raced and the head is lapped to the barrel. My ES2 also has a lapped head (helped by George Cohen) both work well. If you still have a prob after refitting a new gasket, you won’t go wrong by getting Mike to do the work for you.

Funnily enough I was worried my bike had poor compression until I realised the carb (brand new) was completely shut off. Open it a bit and the difference was apparent!

Dan

- Log in to post comments

The old test...

.. of being able to stand on the kickstart for a few seconds only works if you have the throttle wide open.

- Log in to post comments

I don't know about the spigot ,but you could check that a valve rocker is not in contact with the cover when valve is closed.