I took my head and barrels off my 1970 Commando in situ before I found my knackered cam and had to do a full rebuild. My question now is, can I put the barrels on with the engine out and still easily fit the engine back in the frame or even put the head on too? My NVT workshop manual doesnt cover this option.

Suggestion.....

- Log in to post comments

I fitted my barrels and head…

I fitted my barrels and head back on with the bottom half of the engine in the bike (850 Mk3). Too much weight otherwise for me at least to fit the whole engine in one go without any help. Also, I used this method (link to video below) to fit the barrels. Makes it a very easy job.

https://www.accessnorton.com/NortonCommando/installing-barrels-with-two-hands-and-no-ring-compressor.24859/

- Log in to post comments

I find it esy to fit the engine complete.

I fitted my MK2a engine complete last week with help of a mate due to weight. I have used this method quite a few times and it is easy. Fit the front Iso mount on the engine and put the engine in from timing side and fit the x 3 rear studs to engine mount, gearbox already fitted. Then jack the engine up to fit the large Iso through bolt at the front. Job done.

- Log in to post comments

Sounds so easy. I may have a…

Sounds so easy. I may have a go at fitting it with just the barrels on. Fitting the head in situ doesn't seem so bad but trying to wrigle the pistons into the bores at floor level on my own does. I like the idea of putting the pistons in the barrels first and then connecting up the conrods, but clamped up in my old sturdy B&D workmate where I can manage everything at eye level.

- Log in to post comments

I did just that last week…

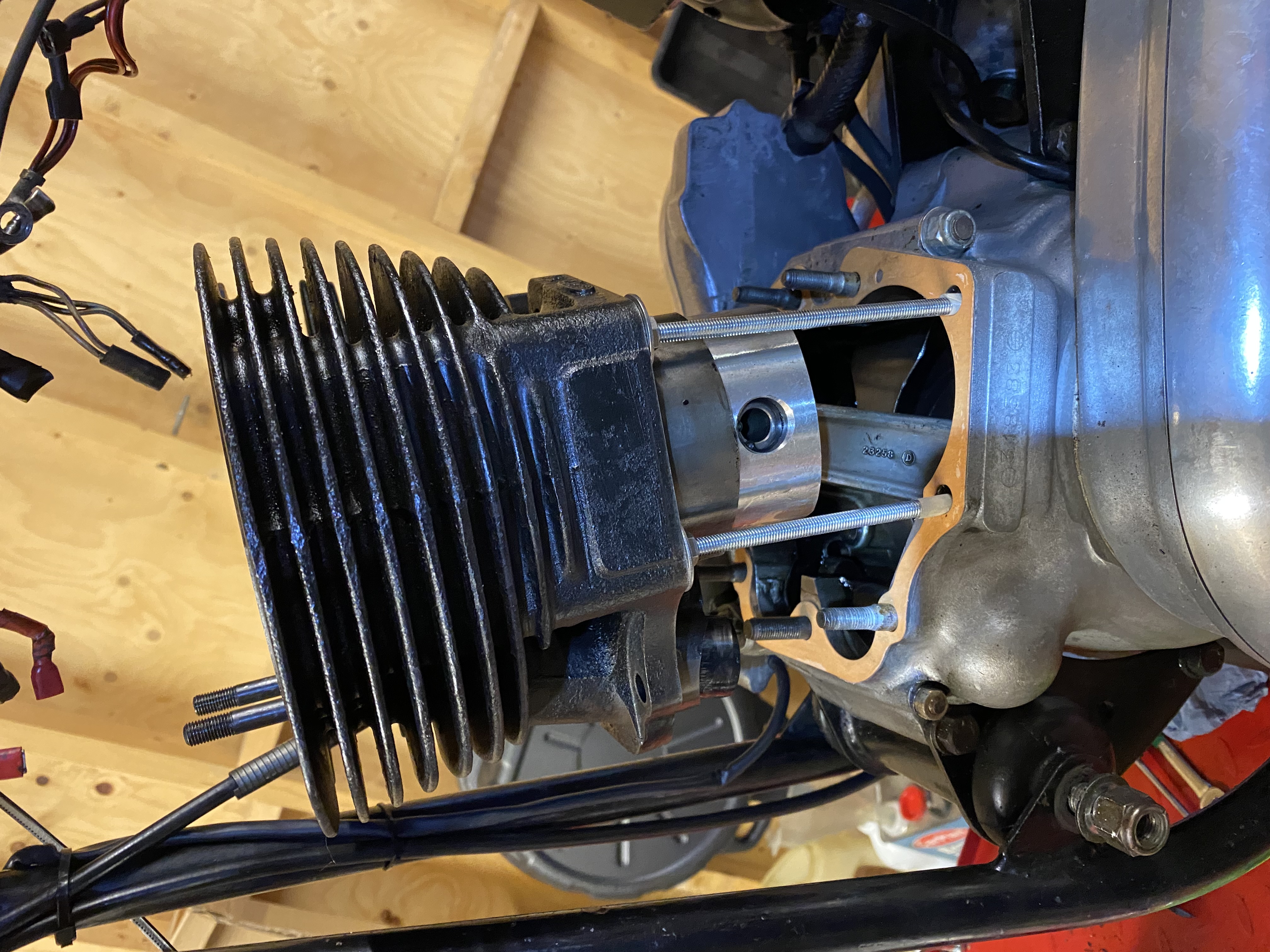

Following a recommendation from a very experienced local engine builder I fitted the new pistons into the barrel on the bench first. Since I was doing this on my own I then used four lengths of M6 studding, plus nuts and washers, to make four adjustable “legs” to take the weight of the barrel then adjusted the length of the legs so the gudgeon pins were lined up with the con rods. Remarkably painless….

Following a recommendation from a very experienced local engine builder I fitted the new pistons into the barrel on the bench first. Since I was doing this on my own I then used four lengths of M6 studding, plus nuts and washers, to make four adjustable “legs” to take the weight of the barrel then adjusted the length of the legs so the gudgeon pins were lined up with the con rods. Remarkably painless….

- Log in to post comments

What I did was...

When I rebuilt and fitted mine a few weeks ago I also fitted the engine complete. Yes it is a heavy lump but with a bit of planning it works for me.

I also fitted the head to the barrel and then fitted that whole assembly to the crankcase. It works for me anyway. I first did this with a Commando I had 15 years ago then repeated it with 2 different G15s I had.

- Log in to post comments

You can fit barrels and maybe head on first, BUT the problem is holding the plot still while you do it. If the cases are in the frame it might be awkward BUT at least the plot stands still while you 'fiddle'. Dropping the head on finally is reasonable straight forward. Having/getting a good engine stand is the first problem.