I have never really taken any notice of the pressure relief valve before, but when reading an old John Hudson engine strip/build article, he stated that the Commando timing cover was changed from the Dominator design to direct the relief valve outlet flow back to the oil delivery pump inlet rather than vent into the timing case (this is also what the NVT Mk3 manual describes). The intent was apparently to reduce the scavenge pump workload, which made sense to me.

Out of curiosity, as my Mk3 timing cover is currently removed, I had a look at the flow routing and found that it just vents through a vertical drilling in the timing cover straight into the timing case.

Strangely, the crankcase has a drilling in the timing cover flange to the oil pump inlet and the timing cover has a matching, but undrilled casting.

I did try searching this website for an explanation but without success.

Any idea why the Mk3 (and perhaps other models too?) would have reverted to flowing the oil into the timing case despite what is stated in the NVT manual?

Andy

John Hudson may have his…

- Log in to post comments

Ashley, the explanation…

Ashley,

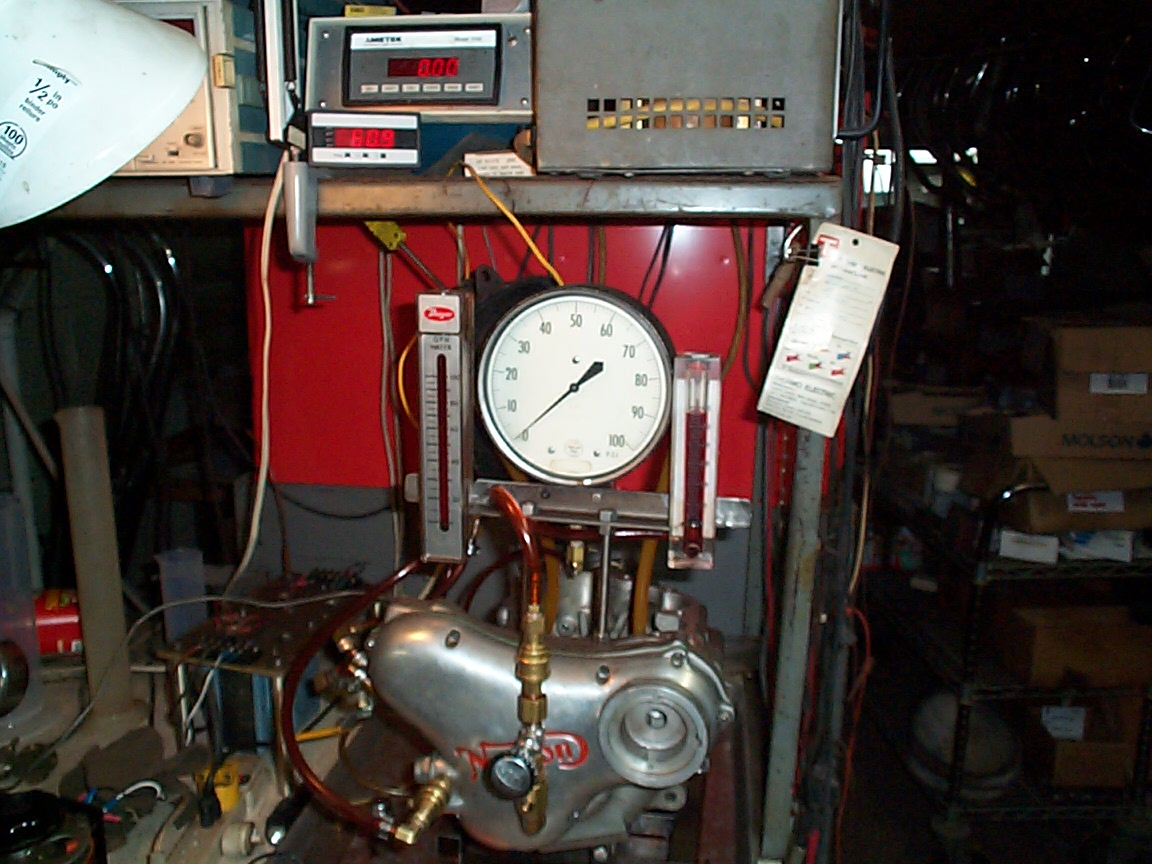

the explanation John Hudson gave was that the delivery pump flows 26 gallons per hour (gph) and of that, 10 gph is relieved by the pressure relief valve. By flowing that 10 gallons back to the delivery pump inlet, which is effectively still clean delivery oil, having only gone through the pump, not around the engine, the scavenge pump only has to return 16 gph.

That was the claim anyway. Somebody must have been able to convince the designers (and accountants) that there was a benefit for the scavenge pump, otherwise why bother altering the flow at all?

- Log in to post comments

The MK3 went back to the pre…

The MK3 went back to the pre- commando route as it is a wet sump leak route and with the new timing cover anti wet sump they had to also close off other routes to make it effective. Its a pity they missed the internal pump link route and used a plunger in the valve and not a ball.

- Log in to post comments

No matter what system,…

No matter what system, recirculating oil back through the pump unfiltered is not good. Once oil has passed through a pump it can contain wear particles from the pump.

The return side of the pump has little restriction to its output, has a larger capacity than the feed side, no matter what JH says it is immaterial. If it was a concern, then the feed side would had to be a greater concern.

When you see his notes regarding the oil feed to the rockers when the 6 start pump was introduced, the testing was to establish a feed rate to the rockers that was close to the 3 start feed pump. Paul Dunstall and Norton race shop spotted the issue, the above idea restricts oil to the cam and wastes the other use of oil, ie remove heat from some of the hottest parts of the engine . We know they had an issue with the standard set up as there are Norton drawings for bucket tappets that are drilled allowing more to the cam and quicker removal of heat. Shame this was never taken further.

This continued as did the increasing failures as modern fuel was introduced that burnt hotter being used in ever increasing engine capacities.

From your own figures above, this shows the oil pump is one of best bits fitted to a Norton, its capacity to deliver oil is brilliant.

- Log in to post comments

oil pump reality

One thing folks fail to acknowledge is the sum of all the physical mechanical clearances does not change, whether at idle or over 6000 rpm.

Separately the oil pump make a constantly variable oil pressure against this fixed exit path. The flow is very much related to oil viscosity.

The OPV dumps when the pressure is to high for the crank seal. Where it dumps the excess is secondary.

Hopefully folks discussing this are aware of the various options for rocker feed and OPV timing chest vent or commando recirculate mode. I have researched it a fair amount as you can hopefully see.

- Log in to post comments

John Hudson may have his words mixed, the workload of the scavenge pump is immaterial in the Norton engine, if they were concerned about that at the time, then why did no one query the even greater workload on the feed side!! A bit like his notes about the 6 start pump output - scary, as the test was only about flow rates, a big mistake. Use an IR thermometer and check out those tappet tunnels after a ride.

The MK3 system is far better, just ride alongside a pre MK3 get off and then feel the oil tank temperature. Recircing oil back through a pump unfiltered is not ideal, it carries pump wear particles and gets hot, with make up only coming from the tank as oil is dispersed via the crank and rocker feed.

Despite this punishment, the pump is a very good bit of kit and lasts well.