Has anyone tried to find an alternative to the standard Commando bronze bush arrangement?

I've seen a couple of mods…

- Log in to post comments

Thanks Peter, I was just…

Thanks Peter, I was just hoping to replace the oily dribbly mess with some fit and forget items.

- Log in to post comments

Thanks for that, I've asked…

Thanks for that, I've asked them for price and availability.

- Log in to post comments

Silentbloc

I drew up sketches and dimensions in 2007 for a frame mounted custom swingarm with Silentbloc bushes to widen the bearing centres for better lateral support.

Decided not to use it after reading Commando engineers concerns about chain tension with the ISOs on a frame mounted unit.

I welded a DIY steel swingarm to the front section and gusset from my Mk3 with its original spindle, bronze bushes and seals in the standard arrangement. See photo below.

Double sided lower shock mounts à la Featherbed were made up rather than the cantilevered bolt through the 8mm thick end plate on Commandos.

Stainless M6 stubs were fitted above each bush, connected by 3mm silicone tube to small syringes tie wrapped to the frame with Castrol EP140 as per original spec. Total loss with the old seals, top up 5ml every 1-2000mls, wipe off excess dribbles as required.

No side play whatsoever at the rear tyre so the stock Mk3 system works perfectly with no wobbles or weaves at any speed.

Simple but effective with at least 45k miles from me plus 40k miles more if they're the original parts. No mention in previous owners service notes of any replacements.

Problem with the Commando is the heavy engine vibes which the O.E. Oilite bushes handle easily

- Log in to post comments

Thanks Neil, that's great…

Thanks Neil, that's great work you have done making your swinging arm, way more than I'm capable of. However I can rig up the lubrication system you have, using a single syringe, hose and T piece.

I didn't consider the flex between the frame, cradle / swinging arm through the isolastics to warrant attention but now you've got me thinking

- Log in to post comments

The bearings

Had a look at the two links, interesting ideas. Is the specification of the bearings known? What's needed are "full compliment" bearings. That is to say, uncaged balls or rollers, Do theses conversions us full compliment bearings?

The reason for this is to spread the load along the raceways, caged bearings will tend to concentrate the load in one small length of raceway, leading to excess wear. Typically, the swinging arm rotates 10 - 12 degrees, not much, so wear will be concentrated over a small area. Ideally, each roller/ball should roll onto the raceway occupied by the adjacent roller/ball, full compliment bearings will do this, caged will not.

The mode of failure will be the classic "Brinell" type failure. Have a look at knackered steering head bearings, small worn patches on the race ways, look like indentations from a Brinell hardness tester, hence the name.

My favoured bearing for this job would be a full compliment drawn cup needle roller, as big as possible outside diameter, running on a hard needle roller inner race, grease lubricated.

Neil W, that swinging arm looks a nice job.

- Log in to post comments

Hello John, the off road…

Hello John, the off road bikes I have use the needle bearings you describe and last well, until moisture gets in, causing galling and pitting but Commandos don't tend to get ridden along muddy streams. The most durable I've had was on a Gas Gas swinging arm, which had nylon or polyethylene bushes running dry on a hard anodised aluminium shaft sealed at openings..

- Log in to post comments

Plain bushes, bronze or…

Plain bushes, bronze or otherwise, are more suitable for the small-angle, reciprocating load of the swinging arm pivot and I'd suggest focusing on keeping the oil in and water out. I reworked the end caps and seals and, using EP80, the oil has stayed at a good level for 3 years. Yes it still loses a bit, but no obvious oily mess dribbling down the engine plates.

- Log in to post comments

Thanks Stan, what did your…

Thanks Stan, what did your improvements involve?

- Log in to post comments

Inner covers - the ones that…

Inner covers - the ones that sit between swinging arm and engine plates:

The standard chrome covers are adequate if in good condition. But the o-rings are inevitably damaged when the swinging arm is installed by the edge of the engine plates. File file/sand a bevel edge and be very careful when installing. Surface of engine plates needs to be in good condition. O-rings should be new and the right size, i.e. the diameter should be about 20% greater than the thickness of the bearing flange, so that they are adequately compressed.

Outer end caps:

Standard setup is just wishful thinking. There's not a lot of room with the standard pre-Mk3 pin and bushes and I've only done this to a Mnk3 swinging arm. Should be possible with earlier arm and Mk3 parts. Make replacement end caps with a radial groove so that the o-ring sits inside the bore of the swinging arm. Select o-ring to have about 10% compression when the end cap will press into place and stay there. A thru bolt is still needed but it's only there to stop the caps dropping out. Fill with oil by leaning the bike over with the left side cap in place and right side removed.

- Log in to post comments

Thanks for sharing that Stan…

Thanks for sharing that Stan. Keeping the oil in there will have it doing what it's meant to.

- Log in to post comments

For anyone interested in the…

For anyone interested in the kits shown in the links by Neil Watkins The price for the swinging arm kit is $378.42 CAD, plus approx. $75 for freight based UK, overseas. Equivalent of about £245 at current exchange. Note: this price does not include VAT, which would be due upon receipt and probably import duties

- Log in to post comments

So, all in with VAT and…

So, all in with VAT and import duty this is about £300. Quite an expensive solution to resolve a potential problem of a small oil weep.

- Log in to post comments

My conclusion too Robin,…

My conclusion too Robin, that's the price of 3 standard swinging arm kits.

- Log in to post comments

Links

The links mentioned are not mine but from Marcal Walti!

Good info from John, drawn cup needle rollers (caged type) on a hardened hollow spindle are O.E. on my Yamaha and very hard wearing once I fitted a grease nipple, notoriously failure prone without it. The entire pivot tube is filled with Miller 2EP Lithium grease pumped through until it comes out the seal caps every 2 years. Now done 63k miles with no excess movement at the rear wheel.

Moisture definitely the enemy of swingarm bearings as Adam says.

I made up a similar setup for my modified Atlas DIY swingarm. Machined caged (not drawn cup) needle rollers with hardened inner races over a 20mm hollow Honda spindle and Yamaha seal caps. You can see these parts in the pic below. Shimmed to the frame for minimum side play at the rear wheel. Swingarm as on the Commando had to be wider to fit 18" radial tyres on 4.25" alloy rims.

Commando Oilite bushes need oil not grease so it can impregnate the sintered bearing structure.

Excellent compact system if everything's in top condition and kept lubricated.

- Log in to post comments

Apologies for my mix up Neil…

Apologies for my mix up Neil and Marcal.

Once again Neil, tremendous work and skills used on your Atlas modification.

- Log in to post comments

Lovely Shocks

Hi, Neill.

Might I ask the make of the shocks & springs shown on your Atlas swingarm? It looks to be a lovely bit of kit.

Thanks!

-Robert

- Log in to post comments

Another type of bearing

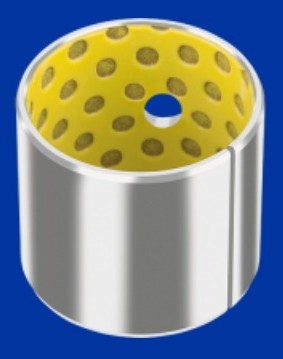

I've used , on another make of bike, Glacier DX bushes. Steel backed plastic bushes. I was sceptical about using these, but they have proven to work very well. They need to be set up rather tight, that is to say, very little clearance, as near to zero clearance without jamming "solid", as any plain bearing in this application to avoid premature wear.

- Log in to post comments

Basics

Adam

You could probably replicate either swingarm, very basic tools used. Levels, squares, straight edges, hacksaw, files, hammer, arc welder, Bosch drill and disc grinder. Plus plenty of elbow grease.

Atlas pivot tube was machined for my needle rollers years ago by local engineer Eric Cheney RIP, famous for his frame designs. I showed him my swingarm sketch and he said said it would work well in the Featherbed frame.

I always listen to sound advice from people who've done it, rather than negative over thinkers telling you why something won't work, without having built and tested it themselves.

The T6 alloy end blocks and carbon fibre facings were from my aerospace/motorsport collection. Drilled holes happened to be the correct size so just hacksaw and file to fit.

T6 alloy plate used to clamp everything flat for alignment and welding also from my collection. Can't recall how we smuggled that out of the building but it has South African Airways stamped on it.

- Log in to post comments

Even better when it costs…

Even better when it costs very little, along with the achievement. Thanks for your guidance and encouragement.

- Log in to post comments

I've seen a couple of mods that others have done. This was along with a swinging arm change to a box section job.

No need with the std arrangement. The achilles heel of the std bush is that the factory fitted a grease nipple to the end caps, so people greased them, this blocked the bush pores and then water and rust did them in. The correct lubrication is EP140w oil.