I have had the bottom end rebuilt by SRM on my 1968 N15, with some NOS +060" dished pistons that I managed to find. I am now looking at putting the head on, but have a few queries relating to the clearances:

1. The pistons are proud of the cylinder by .043", is this normal? I unfortunately didn't take any notice of how the flat topped pistons looked when I stripped the engine. As the gasket is .040" thick, this will put the piston crowns just into the head recess, but there is sufficient height clearance in the recess.

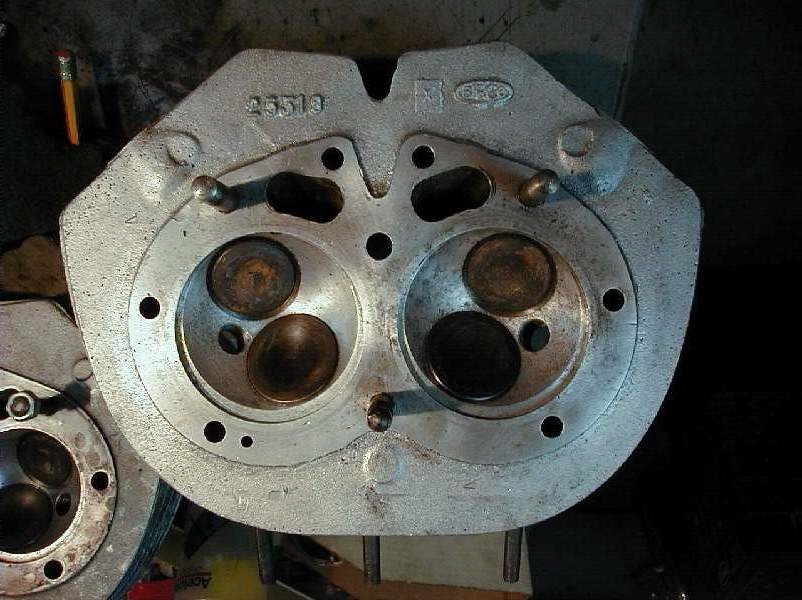

2. With the +060" overbore, I have found that there is only .005" annular clearance between the piston crowns and the head recess, if the piston enters the head. This is a bit of a worry as the head recesses are unlikely to be in perfect alignment with the bores, so there is potential for contact on the edge of the piston crowns. Is this a common problem with the .060" overbore?

3. With reference to the above, what is the solution, do I open up the ID of the head recesses? Or do I fit a de-compression plate to lower the piston height, if it is the piston height that is wrong?

Thanks

Andy

Not enough. I would take…

- Log in to post comments

That is what I will probably…

That is what I will probably do, but it would be nice to know if the pistons should be flush or otherwise, on the Atlas engine.

Andy

- Log in to post comments

Yes, but the angle of the…

Yes, but the angle of the photo makes it look wrong!

Andy

- Log in to post comments

The right hand piston is…

The right hand piston is reversed on the rod. Obvious from the photo

- Log in to post comments

How does the dished piston…

How does the dished piston compare to the 750 pistons available now from the usual suppliers? Do you still have the original pistons? It looks as if the top of the barrel has been machined as well. How much did they remove?

- Log in to post comments

The barrel wasn't machined…

The barrel wasn't machined at this overhaul, it was just cleaned up.

But it might have been machined under the previous owner, as I found a few issues with the internal clearances as the engine was tight to turn over. It had only been run for a short period after a rebore, before I bought it.

It would be nice to know the factory height of the cylinder casting, to check against. When I remove the barrels, I will check the compression height of the dished pistons against the flat tops that came out.

Andy

- Log in to post comments

Would be interested in your…

Would be interested in your findings ,I have a 650 that is very stiff. not had it running at all.

- Log in to post comments

One piston is wrong.....

....I think the Left one is in wrong. Was this done by SRM? Certainly the pistons are differently positioned.

- Log in to post comments

They do look odd, but i…

They do look odd, but i think its the camera angle !.

- Log in to post comments

About Turn

I appreciated that camera angles can lead to distorted views but that Right Hand piston looks 180* wrong. On the 750 engines, the larger inlet valves sit inboard from the piston edges. This in turn leaves a crescent of metal between the valve cutaway and the piston edge.

Below is a late roughly post-1966 Atlas cylinder head.

- Log in to post comments

Not enough. I would take the easy route and fit a compression plate under the barrel. And check the valve action .