My 1936 model 18 had an aluminium head gasket fitted but according to the parts book for 1936 there shouldn't be one. Which explains why I couldn't find one in the catalogues of the usual suppliers. Ive not seen this before so If there's no head gasket should I join the head to the barrel dry or use some type of grease or sealant? Thanks.

On the singles, Norton used…

- Log in to post comments

1948 - 1963 OHV singles.

The single cylinder aluminium head gaskets are a mechanically poor idea on a spigot joint, and as Paul has stated this joint should be a ground fit. These were only fitted to save the factory spending time grinding the joint themselves. When the engines were re-designed for 1948, provision was made for the oil fed to the rocker box to return through drain holes in the head and barrel to the sump. With the ground joint as described, there is a minute gap between outer joint surfaces which will produce an oil leak, unless a sealer is used on this area. A modification can be made by fitting "O" ring seals in suitable counter-bore recesses. Of course, none of the pre 1948 engines have these return holes.

- Log in to post comments

Many thanks for these…

Many thanks for these responses... The head is off having the valve seats recut at the moment but when I get it back I'll follow the lapping process described.

Am I right in concluding that the use of some sort of sealant on the outer surface (ie not the spigot) is a matter of debate?

- Log in to post comments

Since the outer flange is…

Since the outer flange is not supposed to be in contact, there's no point in using a sealant since it won't help to carry gas pressure.

- Log in to post comments

Head Joint Detail

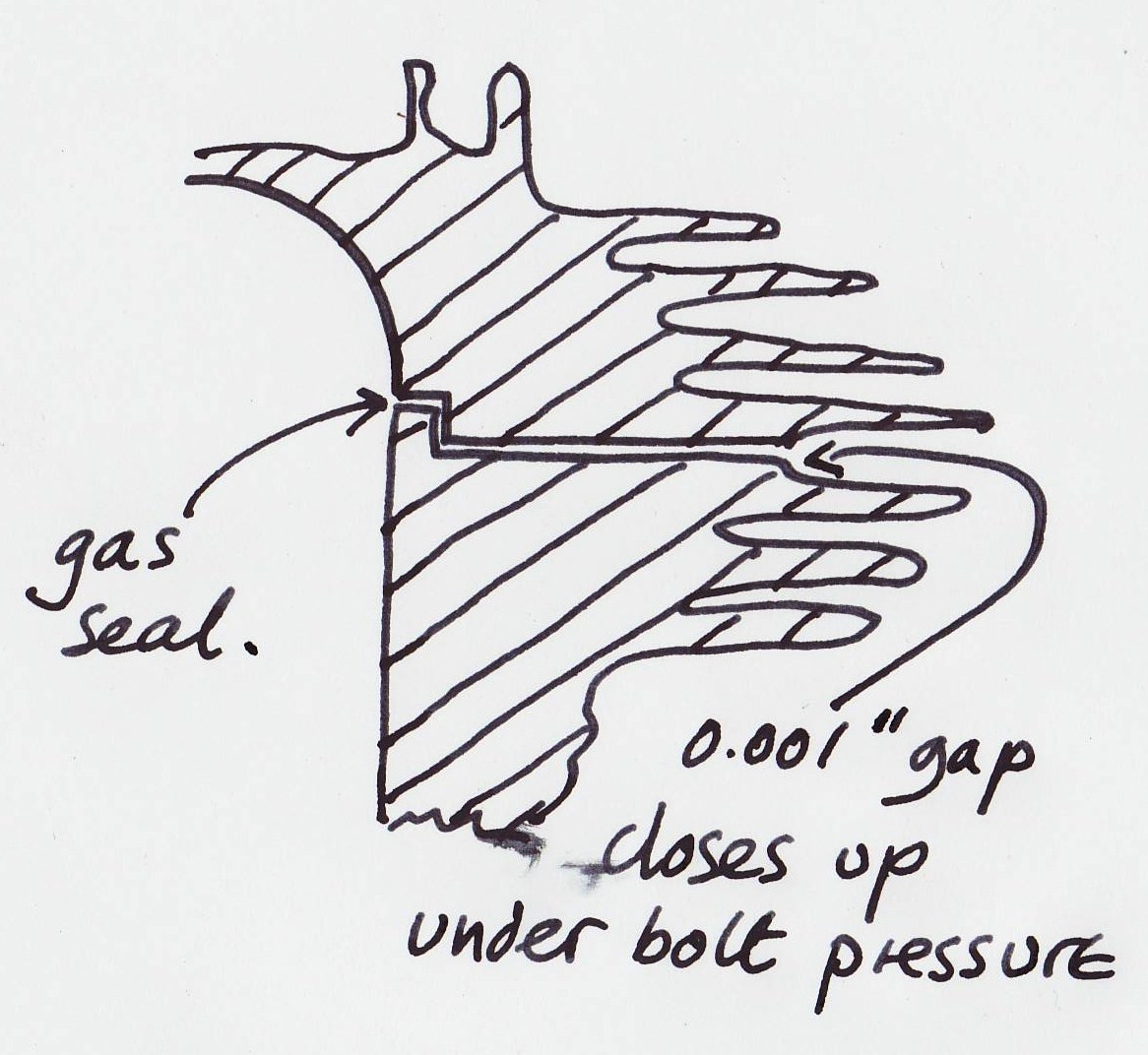

Just to add a little to Paul & Richards description of the lapped joint, here is the late George Cohen's description and sketch.

---------------------------------------------------------------------------------------------------------------------------------

CYLINDER HEAD JOINT

An all the single cylinder engines I have worked on (from an all iron head & barrel twenties OHV to an all alloy sixties DOHC Manx) the same principals and engineering apply.

There is NEVER a gasket. The idea is known as the “double ground joint”.

The theory is simple, the engineering a little more difficult.

The head joint comprises of two parts; the spigot interface and the wider head barrel joint. Say, the spigot on the barrel is 0.125 inch high, then the recess in the cylinder head needs to be 0.124 inch. This means that the seal is at the spigot joint and the wider joint is to prevent distortion.

The practically, especially on well used alloy top ends is a tad more difficult. If you measure the spigot height on the barrel, it is unlikely to be the same all 360 degrees around. The same applies to the wide surface on the barrel. With frequent and less frequent heating and cooling over 50 years the original manufacturing tolerances have been lost and distortion has taken place. On a fifties Manx engine I worked on last year the barrel, at the wide flat surface was distorted by 0.008 inch and at the spigot, 0.005 inch. The cylinder head was worse, with the wide surface being 0.013inch off flat!

Consequently these defects need to be corrected.

Mounting the barrel in the lathe and truing up and machining is relatively easy, but the cylinder head is more difficult. A special jig has to be made up to allow the truing up to be established. A good medium size lathe, grip true facility, magnetic face plate and some clever thinking is required.

The goal is to obtain a double joint with the spigot of the barrel mating in its recess . For Iron head and barrels, there is rarely any distortion and the easiest way to obtain a good joint is as follows: Hold the cylinder head upside down in the vice (securely but without causing any damage). Put some coarse grinding paste on the broad surface and fine in the spigot recess and add a few drops of thin oil to both. Carefully fit the barrel onto the head and with a anti-clockwise and then clockwise rotating motion, lap the two together. After a few minutes, wash of all the paste and oil and inspect. You should be able to see the lapping on all surfaces. Repeat until a perfect face on both broad surfaces and spigot are established.

Torque Iron set ups to 45 ft/lb and aluminium one to 32 ft/lb. You can use a very slight smear of either a hard setting goop or even a smear of oil or grease, which will burn hard.

Hey Presto, no more oil leaks.

-----------------------------------------------------------------------------------------------------------------------

To achieve the gas seal on the top of the spigot, and still close the gap on the wider flange, the spigot should be just 0.001" taller than the recess in the head. If you want to eliminate the aluminium gasket you should measure the spigot and recess on your components. You may find it necessary to skim the head to achieve the correct depth of recess (and note George's comments regarding distortion). Some years ago Mike Pemberton carried out this work on my 19S (Alfin head), together with the valve oil drain o-ring mod. Definitely the right way to go - until then I could never eliminate the oil weeps from the head joint despite frequent changes of aluminium gasket.

Ian McD

- Log in to post comments

Thanks for taking the time…

Thanks for taking the time to provide this explanation.. much appreciated. The head came back with recut seats and I've lapped the spigot as described. All seems in order..

As an aside, I have various books and manuals about Norton OHV singles but never have I seen mention of this arrangement. I guess eventually I might have come across George Cohen's work but it's a good demonstration of the value of the NOC forums.

Thanks again..

- Log in to post comments

On the singles, Norton used a stepped spigot between head and barrel. The joint faces should be smoothe, and the spigot should contact its mating recess in the head before the main joint face. The way to get a good gas seal is to do a finish lap using coarse grinding paste on the main joint faces, and a fine grinding paste on the spigot. When you have even contact all round, wash off all traces of grinding paste, and assemble dry, no jointing compound

Paul