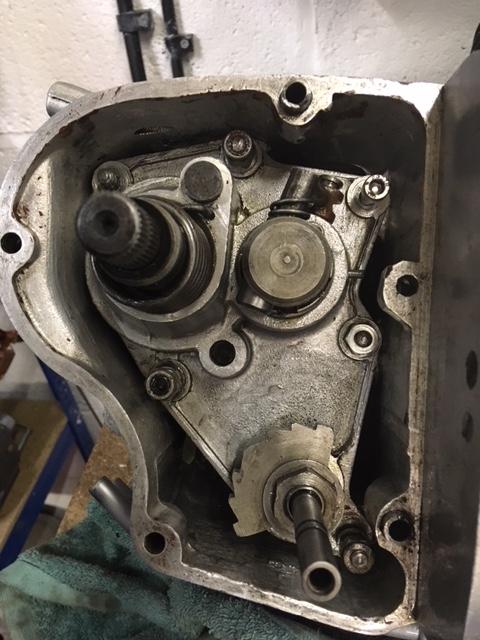

Iâm still having selection problems, I can move the selector cam with a screw driver through the gears with the outer cover off, but donât seem to be able to do so with the cover on, itâs as if the stop plate isnât allowing enough movement. What I donât understand is the spring on the selector rocker, it doesnât really act on the rocker, I can see from a spare (in the photo below) that someone has bent that spring in a bit? I think Iâm happy that everything is together properly and will probably try it with the engine running in due course.

Dan

Dan

Hi Dan, I had a similar is…

- Log in to post comments

Thanks Andrew, Iâll give…

Thanks Andrew, Iâll give that a go, no harm in trying!

- Log in to post comments

Dan, on my Commando it is…

Dan, on my Commando it is basically the same mechanism.

The manual says there should be a slight gap between the spring legs and the pawl.

So on your photo it looks ok.

Is the inner cover all the way home?

There is missing a nut on the top left side and the others look loose.

Did you shim the kick start shaft?

Without shimming my gearbox slipped out of

first gear after I shimmed it about 2mm it is ok now.

- Log in to post comments

Dan, nothing looks obvious…

Dan, nothing looks obviously wrong to me but both Andrew and Uli have fair points to check. Are the spacers properly in position under the selector plate which was mentioned by Andrew. However the spring looks a little bit bent out of shape to me; On all mine the spring just lightly touches on both sides of the rocking pawl. Also as Uli has mentioned the six nuts holding the inner plate seem either loose or one missing. This definitely could make a difference.

I don't think shimming the kick shaft would make any difference but in mine when it jumped out of gear it would at least select the gear -but then jumped out under load.

- Log in to post comments

I spent ages with a dial g…

I spent ages with a dial guage shimming my layshaft to perfection but found the best gearchange was after I left the shims out. Had to accept a compromise in the end.

- Log in to post comments

The lose inner nuts are de…

The lose inner nuts are deliberate! the inner cover is held in place with two that are tight at the moment, I put the others back in before I took the pic so I didnât lose them ! I did put the gearbox back together fully when I was hoping the problem was just a lack of oil ...... it wasnât! It had the same problem. Iâm pretty sure the gearbox itself is fine.

I havenât shimmed anything yet, but have replaced the sleeve gear bearing, main shaft bearing and layshaft bush which I have loctited and pegged. With the inner cover fully attached it selects gears ok when I move the selector cam by hand so Iâm pretty sure itâs the rocker not engaging sufficiently.

If the spring is supposed to gently touch the rocker then it would have to be bent inwards slightly as the selector plate, if thatâs the right description, holds it open beyond the rocker. The spring that is fitted, did come out of a working gearbox.

Ill have another look this afternoon, if it warms up a bit!

- Log in to post comments

The Maintenance Manual for…

The Maintenance Manual for the Jubilee says "before fitting, set pawl carrier lever pointing towards kickstarter bush and set the pawl square with the lever. Fit cover, holding pawl spring and washer from moving until the quadrant shaft has entered. "

It does mention that the partly dished washer is fitted with its longest flange outside the spring and that it lies between the spring and the pawl carrier. It doesn't give any info on setting the spring but I still think this is the likely culprit.

It's lovely sunshine here - 17 degrees in the sunshine- and I have a ton of soil to move from one end of the garden to another area 100 metres away. Good exercise with a wheelbarrow !!.

- Log in to post comments

Thanks Patrick, thatâs pr…

Thanks Patrick, thatâs pretty much what Iâm doing,

I was fixing the plastics on the Scramble Club quad this afternoon so didnât get to the garage, but did look at the box, the washers are acting as stops for the pawl lever, and my spare cover has much smaller washers so will try thatband keep my fingers crossed!

Weve also moved about 2 tons of subsoil and have another 3 to go, down hill fortunately! Weâre building a small dam to make a pond in the paddock.

Dan

- Log in to post comments

Hi Dan, I did a pond a cou…

Hi Dan,

I did a pond a couple of years ago but I cheated with that - I borrowed a 360 tracked digger from a local builder who kept his big machinery in some old farm buildings - I only had to put in some diesel . That was good fun as I had never driven one of those before; it is not nearly as simple as I first thought but I can now handle it pretty well. At 13 tonne though it is a bit on the big side to take into the vegetable patch- so that's a spade and wheelbarrow job. Anyway I can now say the potatoes and the broad beans are in- next job is to weed the strawberries . A story of every day country life.

Sounds like a episode from the Archers.

- Log in to post comments

Hi Dan, Your outer cover l…

Hi Dan,

Your outer cover looks OK - the pawl spring looks ideally shaped & is holding the pawl in the correct position. The other spring looks fit to throw away - its bent completely the wrong way.

However, I do see one thing that does not look right. The centre of your dished washer shows signs of rubbing - see photo.

From what you write - I can't figure out exactly what item is not working?

Your stop plate looks to be an early design - the later ones were a one-piece pressing, but that alone should not be an issue - either will do the job.

Does your stop plate have the two washers (item 9 in parts list) behind it?

Attachments rubbing-png- Log in to post comments

Thanks Andy, Yes the plate…

Thanks Andy,

Yes the plate has 2 washers behind it, interesting what you say about the spring, Iâll have a look and see if I have another. The inner cover is from a different engine so am not sure whether the washer is still rubbing or not, but the selection problem exists whether I have the cover loosely fitted or tight so donât thing that is the (main) issue.

The plate certainly has 2 different washers and the pawl carrier uses them as a stop. My spare cover has washers that are no bigger than the bolt heads. Which would give at least 1mm more movement each way

Iâll have another look and report back.

- Log in to post comments

Update - I changed the sto…

Update - I changed the stop plate and fitted it with smaller washers and also changed the return spring, I kept the pawl spring and reasonable success, I now get all gears, Iâm hoping when full of oiled and engine spinning it will be all good!

Unfortunately after Iâd finished I found a ball bearing and circlip on the bench so took it all apart in case Iâd forgotten to put the ball in for the clutch rod ..... Sodâs law I hadnât forgotten, this was obviously one of my spares! Iâm hoping wire the circlip is from the ES2 piston, as I couldnât find anything in the book about a gearbox circlip!

Last thing is I fitted a new primary chain from the club, but itâs pretty tight, itâs almost perfectly adjusted without the tensioner in place, is that normal for a new chain?

dan

- Log in to post comments

Previously Dan Field wrote…

Previously Dan Field wrote:

Update - I changed the stop plate and fitted it with smaller washers and also changed the return spring, I kept the pawl spring and reasonable success, I now get all gears, Iâm hoping when full of oiled and engine spinning it will be all good!

Unfortunately after Iâd finished I found a ball bearing and circlip on the bench so took it all apart in case Iâd forgotten to put the ball in for the clutch rod ..... Sodâs law I hadnât forgotten, this was obviously one of my spares! Iâm hoping wire the circlip is from the ES2 piston, as I couldnât find anything in the book about a gearbox circlip!

Last thing is I fitted a new primary chain from the club, but itâs pretty tight, itâs almost perfectly adjusted without the tensioner in place, is that normal for a new chain?

dan

There is an outside circlip on the shaft of the gear selector retaining the selector plate. An internal circlip will be used in a piston to retain thegudgen pin.

GRAHAM

- Log in to post comments

Thanks Graham, itâs not t…

Thanks Graham, itâs not that one so Iâm good to go!

- Log in to post comments

Hi Dan,

I had a similar issue and found that the washers under the two bolts clamping the selector plate (the one with the slot in it) were too large and stopping the selctor moving far enough up or down, I suggest you try with out the washers to check.

Regards

Andrew