because I’ve got a whole load of them, or more precisely a whole sump full of them.

I was out for a short ride today when the engine just died. Luckily for me, after pushing the bike for half an hour, a ‘white knight’ NOC member (George Farenden) turned up quite by chance and gave me a push start. That got me home but worse was to come.

When I rebuilt the engine on my 99 basket case the cam followers and camshaft I got with the engine had definitely seen better days. The followers were badly scored and the cam lobes had chunks missing. So I had the cam followers re-profiled by Newman Cams and bought a new QR cam from Norvil. On the dry build of the engine I checked that the followers met the faces squarely and full width on the cam lobes and then smothered everything in assembly lube. However, after just 200 miles of careful running in, I am getting huge amounts of metal stuck to the magnetic sump plug. Most of it is ‘iron filing’ type stuff but there are also some big flakes (approx 4mm by 3mm by 1 thou thick). The bigger flakes look very polished on one side, so I’m guessing that’s cam lobe material. So I guess it’s engine strip down time ( and probably new cam and followers - ouch!).

Has anyone else had this sort of problem or have I just been unlucky?

Thanks

Regards

Tony

Something has to be amiss, I…

Something has to be amiss, I am running my orriginal cam and followers from 1960 and no measurable wear. No filings on my magnets either. New cams /followers must not be allowed to idle at first , Cam tunnel must be filled with oil by pouring some down the pushrod tunnels . Valve springs must not get coil bound .followers must move freely over full action. valve rockers must not hit the underside of the head.

- Log in to post comments

I don't know about the…

I don't know about the earlier cam followers but the later ones are stellite tipped, so if they are wearing then its non magnetic so the iron fillings are from the cam.

- Log in to post comments

The mystery is solved. I’m…

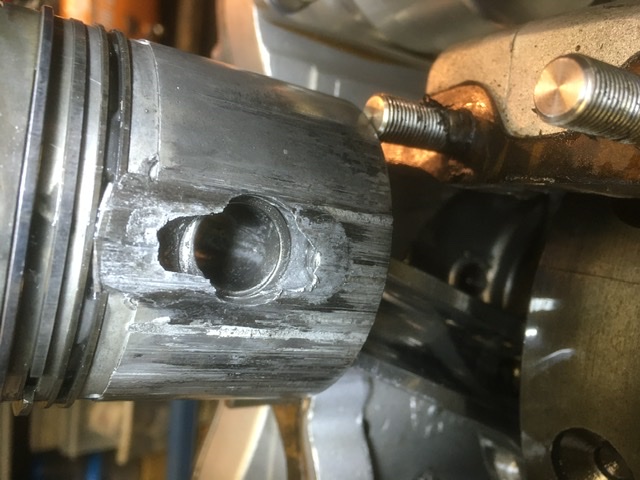

The mystery is solved. I’m pleased to say that the cam and followers look excellent - no wear in any component. That pleases me because it means it wasn’t my build technique that caused the problem. However, I have discovered the issue. I had the crankshaft dynamically balanced by T&L Engineering of Bedford and they seem to have got things a bit wrong. I had managed to find genuine NOS Hepolite pistons but when T&L weighed everything, one piston and gudgeon pin weighed 5 grams more than the other. The only thing was there wasn’t enough meat on the heavier piston to remove 5 grams. “No problem” said T&L, “we’ll simply make a 5 gram slug and press it into the gudgeon pin of the lighter piston”. So that’s what they did. I asked if it had been Loctite or welded in place and T&L assured me that once the slug was fitted (pressed in), it would never move. I guess some of you have already guessed the next bit. The slug came loose and has dug into the cylinder walls (both left and right walls) leaving long vertical scars about 1.5mm deep, it also broke the eyelet ends off the gudgeon pin circlips and destroyed the right-hand piston. The oil control ring is jammed solid in its groove by a large smear of aluminium and most of the piston metal around the gudgeon pin area has just ‘gone’ leaving the circlips jammed in their grooves. I’m not sure how I’ll remove the piston - maybe Dremel away the lip around the circlips to free the circlips without damaging the gudgeon pin. It all looks very expensive to fix - I’m going to talk to T&L this afternoon.

Oh well, it’s only taken me 4.5 years to get the bike going so I guess another few years on the bike lift won’t hurt.

Regards

Tony

- Log in to post comments

I'm sursprised..

.. they couldn't remove 5 grams from the piston as that's nothing. I'm even more surprised at their "solution" as again a 5 gram slug wouldn't have enough meat to press in securely. A 1p piece weighs 5 grams!

- Log in to post comments

Why not take 5g off the…

Why not take 5g off the heavy sides gudgeon pin if the piston could not take it.

- Log in to post comments

Hi Ian and John. I’m not…

Hi Ian and John. I’m not sure why T&L opted for the metal slug route - probably easiest. According to them they’ve never had on move before - just my luck!

Regards

Tony

- Log in to post comments

Hi Tony, I am most impressed…

Hi Tony, I am most impressed by your determination in the face of the setbacks . I'm pretty sure I removed more than that from the Atlas pistons when i found how much heavier they were than the orriginals. You seem to have had plenty of issues. I think I am due for some sort of award for the most breakdowns on our surrey runs out. After talking about punctures I found my tyre flat . Don't tempt fate!. The AA did good. Far better than the RAC clowns.

- Log in to post comments

Has anyone used JP pistons…

Has anyone used JP pistons and rings? T&L Engineering have offered to replace my NOS Hepolites with JPs but I’ve seen a few bad reports about rubbish JP piston rings (very long/non-existent bedding in times, high oil use, smoking exhausts). If you have used JP pistons, what rings have you ended up using if not the original JP items?

I’m going to let T&L do the engineering work (re-sleeving the barrels, re-balancing the crank etc) but I’m going to do the engine rebuild as I want to be in control of it.

Thanks

Regards

Tony

- Log in to post comments

JP Piston

Tony,

I used A JP Piston in my ES2.

It had all the issues you mentioned plus it was about 40 grams heavier than the old piston (BSA I think)

I got sick of all the smoke so I got a GMP piston. It is very good, rings bedded in almost straight away.

I've also got them in My Atlas. No problems their after about 8 thousand miles.

Don Anson

Melbourne

- Log in to post comments

J P Piston

I had a similar experience to Don when I fitted standard size JP pistons to my re-sleeved 650SS some seven years ago. They were way heavier than the old +60 thou ones and caused much worse vibration plus the rings were taking ages to bed in causing much smoking. I ended up with so much oil getting past the rings into the silencers that when I had to stop in traffic the oil in them smoked like mad, which was rather embarrassing. In the end I gave up with them when there was little improvement after 750 miles and fitted a set of Gandini pistons and rings which were pretty much perfect from day one with almost instant bedding in and with them being about the same weight as the old pistons my vibration problem was gone. I had even tried getting the engineers who did the rebore to lighten the JP pistons but they were so far out they couldn't remove enough to improve things. If it was me I'd steer clear of them unless you can't get anything else.

- Log in to post comments

JP pistons have their uses,…

JP pistons have their uses, ie only when absolutely no others are available and only if non JP rings are used.

- Log in to post comments

This is what happens when a…

This is what happens when a gudgeon pin slug makes a break for freedom

- Log in to post comments

Don't think that will polish…

Don't think that will polish out !!. Are you taking the motor right down ? I would expect rubbish to have got in everywhere. If you are re-sleeving and cant find good new pistons you could get some good standard size SH solid skirt 650 pistons and bore to fit those , I would go for 4 1/2 thou. clearance which may be a few thou less than a std bore so ring gaps need carefull work.

- Log in to post comments

JP piston experience (Dross Warning)

After a worn bore on my +60 ES2 (Poor man's Manx) and a lot of smoke (about 9 years ago), I had the barrel re-sleeved and fitted a new JP piston, complete with rings already fitted.

At the time I didn't realize the weight issue. The engine ran well but was a little lumpy to what it was, not enough to warrant taking the barrel off and decided to live with it.

2,600 miles later it is still running well. (Just slightly lumpy over standard, but not much)

While on the subject; I found that GMP rings work well with Hepolite pistons where there is a little bore wear (16,000 miles on my 99) Same goes for Cords rings on singles. In both cases they save the early cost of a re-bore. Well done Tony for sticking with it. Thanks for sharing...Good Luck.

- Log in to post comments

I’ve stripped the engine…

I’ve stripped the engine completely. My next job will be to wash every item to remove any traces of metal rubbish. The piston material has combined with the oil to form a silver coloured oily residue that’s covered most parts. The engineering company that did the work are going to vapour-blast the big lumps, such as the crankcases and head. They’ll also clean out the sludge trap as I bet it’s got some muck in there now.

The main bearings seem fine although the timing side ball bearing has discoloured - looks like it’s been affected by heat. Should I change that one?

I’ll also get the big end shells replaced as they may have been contaminated.

Isn’t classic bike ownership fun!!

Regards

Tony

- Log in to post comments

The next step (Dross Alert)

Hi Tony,

A bit obvious but don't forget a thorough clean of the oil tank, etc.

How the oil pump never got wrecked I'll never know but I'm sure you will service it.

Looks like you will need to re-sleeve the barrels, don't forget to hone them.

As for your T / S bearing: Wash it in some clean petrol (Ethanol stuff is OK for this) then examine under magnification for damage and wear. Check they rotate smoothly and if so, oil up, wrap up and ready for re-use. Any doubt, sling it out.

You are never bored with a classic bike, apart from getting the rev counter to work via a magneto on my last build, a Dommie Racer, I thought I had them all sorted. But after starting my Mk3 Commando today; I find I have some electrical issues.I was planning to re-fit the electric start next year, God willing, so the whole lot can wait till then.

ATB...

- Log in to post comments

Make them pay

Surly the engineering company should be replacing all the bearings, seals, gaskets and the pump for you, Its the least they could do. Why should you be out of pocket because of their mistakes? You could have taken the whole bike to them and demanded they put it right or you would sue. It could have resulted in a nasty accident, they’re getting off lightly.

Al.

- Log in to post comments

Yes, but not on a Norton (apologies to Al Oz). I fitted a new camshaft to an A10 and shortly after the filings appeared. I had the camshaft tested at the local Uni engineering department and they confirmed that it had never been hardened.

So either the camshaft or the followers have lost or have never been hardened. I suspect the followers may have lost their hardening as a result of the re-profiling.