Can someone tell me what the compression pressure should be for a newly rebuilt 1961 ES2 with rebore, new rings, etc.?

Mine is reading 90 psi (at 1000m asl).

Is it about right - the bike doesn't have much power?

Sounds low, but

- Log in to post comments

Hullo George

Thank you.

Full throttle, yes; Kicking it 4 or five times as fast as I can; Cold engine;

It has done only about 30 miles. Pushrods are free.

It is definitely low on power, something is wrong. Need to change down for even the mildest of hills. Has also nipped up twice on hills, frees again after a minute. Have not had a real seizure.

Has a 376 carb, 3-1/2 slide, 106 needle and jet, needle in middle groove. Main jet is 230 but hasn't been used yet.

Ignition is at 38 d fully advanced. Plug is slightly sooty, but not too bad

Can you give me an idea of what the compression pressure should be, in your opinion?

Richard

- Log in to post comments

I just did a compression…

I just did a compression test on my 36 ES2 ( 38 motor ) as i was curious. I got 125lbs.

- Log in to post comments

Richard, check your valve…

Richard, check your valve timing, by which I mean the actual valve events, with a degree disc, the timing marks cannot be trusted on any of these engines.

Good Luck!

- Log in to post comments

Exhaust valve lifter cable

Richard,

I had a problem with compression on my 1955 ES2 and eventually found that the exhaust valve lifter cable was sticking, so may be worth checking yours is allowing the valve to close fully. This became more of a problem when the engine was hot.

- Log in to post comments

Thank you all...

.. for your help and advice.

I certainly will do these tests tomorrow.

(I removed the valve lifter, I found I did not need it!)

Richard

- Log in to post comments

Richard, My 1956 ES2 took…

Richard,

My 1956 ES2 took ages (700 miles) to run in and nipped up a couple of times when very new with a JP piston and rings. On a number of occasions it would loose compression when cold and needed a squirt of oil down the spark plug hole to get compression back. It would blow a lot of smoke until it warmed up as well.

I eventually got sick of it and bought a GMP piston ( and blocked off the oil feed at the back of the barrel but that is another good news story) and haven't looked back.

It goes very well now but I wouldn't know what the compression pressure is.

Don. Fro m Melbourne.

- Log in to post comments

Don't need a valve lifter? …

Don't need a valve lifter? That doesn't sound right. Can you get it past compression that easily? To start mine, I retard the ignition a bit, slightly tickle the carb, move the kickstart just past compression using the valve lifter, just the tiniest bit of throttle, then give a long, slow push on the kickstart and advance the ignition as soon as she fires. I couldn't get past compression without the lifter. How do you do it?

- Log in to post comments

A busy day...

I checked the compression again (cold, throttle open, kicking hard 4-5 times.). It was about 90 psi again (I'm at 1050m asl, so that's about 102 psi at sea level). I put a few teaspoons of oil into the plug hole, the compression was then about 109psi (124 at sea level)

I checked the valve timing by measuring the valve lift at TDC. They were roughly the same, about 1.5 mm open (inlet opening, exhaust closing). I think that means it is correct, the gear marks are all in line. If it was out, a correction of 1 tooth would change the timing by 9 deg. That would be a large change, one valve would be way more open than the other.

To start it, I simply get it up to compression, throttle half open, jump down with my weight on the kickstart and away it goes. I weigh about 70kg. It always starts second kick after tickling until a few drops drip out of the carb.

In the next few days I'll look at the auto advance again.

BTW, there is no sign of oil inside the rocker box when looking into the valve adjusting opening. It's dry. Is this usual?

Thank you for your comments and help.

- Log in to post comments

30 miles is not much at all…

30 miles is not much at all to bed rings in, run it for a few hundred more and then check it. In the meantime open the throttle fully for a few seconds every now and again to get the combustion gases behind the rings so they wear against the honing and bed in and not glaze the bore. If you have JP rings then they may never bed in, just too hard a ring to wear in against the honing.

- Log in to post comments

It never hurts to put a …

It never hurts to put a (gloved) finger over the oil return pipe by the oil tank filler cap to force some oil up into the rocker box, sometimes after a rebuild or a long sleep it can be a bit reluctant.

The figures you report should be plenty, but not needing the lifter sounds wrong, my Model 50 will hold my weight for 2-3 minutes (only a 350 and I really did eat all the pies ) and I always need to use the valve lifter, when I didn't the performance was very flat, so I checked the timing properly and found that the exhaust cam needed advancing a tooth from the marks, which made a massive improvement. I also tried different sets of cams, all standard and they varied quite a bit, as do the crank pinions..

Since you are at quite an altitude, is your mixture right?

- Log in to post comments

The performance ...

...of the bike was so poor that I really think something basic is wrong. I'm going to check that the valve timing is exactly as it should be using a degree wheel and that the advance is working properly. I did of course check these things in putting it together but I'll check them all again.

Thanks again.

- Log in to post comments

Leakdown check....

.,,,is in order before anything else. Find out if and where compression is being lost.

- Log in to post comments

Ignition timing.

Hi Richard,

If you have the standard flat top piston, 38 degrees fully advanced sounds too retarded. This figure would normally be used with a 9 to 1 compression ratio. You could try 45 degrees and see if there is an improvement. Different fuels and altitude can make a difference so this is just a ballpark figure.

- Log in to post comments

Thank you Richard....

... the bike certainly "sounds" too far retarded - flat dull sound, no crack to it. And feels it going up hills. I got the 38 d from the Bacon book.

I'll certainly try it but maybe in smaller steps. (I'll leave the primary case cover off!)

- Log in to post comments

Valve timing

The valve timing is exactly as the Bacon book states. Checked this time with a proper degree wheel and pointer needle.

I will set the timing to 40 deg and then 45 after testing.

- Log in to post comments

Ignition Timing

The 9th Editon of Haycroft's "Book of the Norton" covering '55 - '62 ES2's gives the advance as 17/32" btdc for'59 -'62 coil ignition models. Someone else can work that out in degrees!

George

- Log in to post comments

In degrees..

.. that's exactly 30 deg, George.

Doesn't sound correct, should be 38.

- Log in to post comments

When timing with the 18D1 c…

When timing with the 18D1 c/b unit, isn't it done to the retarded figure? How would you hold it in the advanced position?

How much advance does the 18D1 give?

I have never used one on mine, I thought it looked like junk so I fitted a K1F magneto off a Velocette.

What do you have on yours?

- Log in to post comments

The lucas distributor is…

The lucas distributor is timed with the advance a retard unit held at full advance ,I seem to remember fitting a cup and screw washer to the spindle to lock it in the full position. You can also mark the alternator /housing and use a strobe.

- Log in to post comments

Advanced timing....

.... is set by removing the cover on the distributor (it isn't really a distributor is it, with one cylinder) then using a long handled screwdriver in the slot at the end of the shaft, turn the shaft clockwise gently, this will open up the mechanism to fully advanced. Then rotate the distributor slowly (you've loosened the clamp) until the multimeter tells you the points have just opened. Tighten the clamp bolt and check with a strobe at about 2500 rpm, fully advanced should have been reached by then. With mine, I need to get someone to sit on it to stop it running around the garage floor at these revs!

- Log in to post comments

Distributor advance.

My auto retard mechanism is stamped 15d. That gives 30d at the crank, so retarded is 8 deg btdc.

- Log in to post comments

es2 compression

90psi compression was what my 1961 ES2 had after I freshen the top with new piston and rings. The owner manual for this bike has a very long break in period. If that is for the piston and rings to seat I don't know. It roughly says for the first 500 miles not to exceed 40 mph for the next 500 miles limit your full throttle blast. I have about 800 miles since the work was done and it runs much better, but I haven't checked the compression level. I'm at about 1200 feet above sea level.

- Log in to post comments

ES2 seizing

Thank you Gregory, that's helpful.

Now that I have done about 100km (60miles) on the bike, the situation is not good.

It nips up (seizes) on even the slightest uphill, even with the throttle no more than about 1/3 - 1/2 open.

It starts again almost immediately - after a minute or so.

It's using a 389 carb, 3-1/2 slide, needle in mid position.

Clearance piston to barrel front is 4 thou, side is 5 thou, ring gaps about 13-15 thou.

Timing is set to 38 d. Valve opening and closing are as specified.

But I don't know if oil is getting to the hole at the rear of the barrel. This should lubricate the thrust face of the piston.

Stripped it yesterday, the piston has seize marks at 45 d off front to back, see photo. No real seize marks on the piston thrust face (rear) or front. No damage to the rings or top of piston, but the exhaust valve is white in the center, black on the edges. Inlet valve is black. Plug doesn't show signs of overheating. Oil is circulating ok, tank was about 60 C after about 20km. Cylinder head temperature deep inside the fins about 5 minutes after switching off was about 140C. Barrel shows some marking but hopefully not serious.

Knowledgeable people I have spoken to here have not seen such score marks. I'm taking it to specialist engineering shop tomorrow.

Has anyone had or seen such seize marks previously, or have any idea what the problem is?

- Log in to post comments

Looks like a 4 corner…

Looks like a 4 corner seizure caused by overheating and expansion. I would clean up the bore and use a very fine file round the corners . Definately richen the mixture by raising the needle 1 to 2 notches , May be worth trying a 3 slide. Also check your fuel flow is not restricted. What number needle jet?.

- Log in to post comments

Cause of seizure.

Hi Richard,

Your piston skirt looks like it is circular when it should be cam turned so that the sides have much more clearance than the front and rear faces. 5 thou is O.K. for the thrust faces but this should only be about 1.5 inches across and then increase gradually to around 10 thou on each side. This allows the piston to expand with-out seizing. The exhaust valve looks like it is getting too hot, which could be a weak mixture or retarded ignition or both. If you have two petrol taps, turn them both on when starting to make sure there are no air locks in the pipes and once running turn off the reserve side.

- Log in to post comments

I agree with Robert

I agree with Robert.

I would clean the score marks off with a file and richen the mixture up.

Maybe even give the barrels a light hone.

Phil Irving made a point of always holding the piston in your hand not in a vice when filing out score marks.

If it goes back together and dosent rattle too much you haven't lost anything.

Also one of the guys in my club says it's not run in until it has nipped up 3 times!

- Log in to post comments

Thank you for your advice.

The needle jet is 106.

What surprises me about this is the ease with which it seized. Having done so few miles I was nursing it, changing down for each incline no matter how slight.

Today I intend to take the piston, barrel, rings etc to a specialist shop to get their comments (and advice?).

It probably needs honing anyway.

- Log in to post comments

I also agree with Richard, …

I also agree with Richard, Not enough clearance to start with. Piston may not be the ideal shape.

- Log in to post comments

I agree...

... insufficient clearance. Edgar Franks said that a rebore was only necessary when the clearance had reached .007" over standard - ie about 12 thou! I always err on the larger piston clearance and put up with a small amount of piston slap rather than having to pussyfoot about for months.

I had a similar problem with a 1931 Sunbeam 350 which was cured by having a couple of thou honed out of the bore. It had been rebored by a previous owner.

- Log in to post comments

Clearances

The engineering shop I visited today measured everything and said the clearances are fine. However most of their work is on truck engines so maybe not valid.

They said overheating, check the ignition and the mixture.

They honed the barrel for me, so I'll dress down the piston.

Interestingly, I took out the exhaust valve and found that although the face was white (showing overheating), the back side and sealing face are black and thick with carbon. Too much oil in there somewhere?

To check that the oil is going where it should, I intend to spin the crankshaft - driving via the large sprocket nut and an electric drill. Sounds crude I know, but I should be able to see if oil is coming out of the rear barrel feed hole, and up past the big end. It's worth a try anyhow. Does anyone know of a way to measure the oil pressure on this engine?

- Log in to post comments

Its likely that as the oil…

Its likely that as the oil is not getting into the chamber but is accumulating on the back of the valve ,its probably leaking down the ex valve/guide or guide bore . Sometimes you can see a pattern on the back of the valve head or ex port . This does not always show up as much smoke in the exhaust as a poor piston ring or inlet valve oil leak which gets burnt in the combustion process.

- Log in to post comments

When I got my ES2 it was…

When I got my ES2 it was seizing up. I took the barrel off and found that the piston to bore clearance was too small and it had scuff marks on the back of the piston and bore. I cleaned up the bore with a hone and it came out to have .006 clearance for the new piston. I also opened up the oil passage at the back of the cylinder wall which was closed off. I followed the break in procedure and haven't had a problem since. I have ridden on 90 F degree days without a problem. I also use the 50w crankcase oil recommended in the 1961 manual. I ride mostly in the country and now have about 1200 miles since I put in the new piston

Greg

- Log in to post comments

Further work

Well, I did spin the crankshaft with the barrel removed, no piston and with the con rod held vertical with a couple of bungee cords (elastic straps). Worked fine by kicking it (the electric drill suggestion didn't work), could get it up to about 4-5 revs per second with no drag from the piston. Oil came up out of the rear feed hole to the barrel and out of the big end. So no problem there now.

I removed the seize marks (couldn't do anything about the few gouges) with waterpaper so took off about 1/2 thou from the corners of the piston.

I've put it all together, started it briefly last night, it sounds fine.

I'll try to take it for a gentle run later today, after the F1 qualifying!

- Log in to post comments

I suspect that I have been…

I suspect that I have been somewhat less than careful in the past to gently run in a reassemble engine. Somewhere I have instructions from the 20's or 30's to disassemble after the first perhaps 100 or so miles and gently file off high spots on the piston. I suspect they were writing about cast iron pistons...

- Log in to post comments

1/2 Thou ??

Hi Richard,

I don't think half a thou will be enough to cure the problem. Where the seizures have picked up on the skirt, you need at least 3 thou more than the front and back clearance and much more on the sides. Think of a slipper skirt piston and you will see the side skirt doesn't need to contact with the cylinder wall.

- Log in to post comments

You're right...

Thank you Richard, Gregory, I've decided that I will go the way you and others suggest. I assumed that the engineering shop was correct in their assessment of the sizes, but now from what has been said on this website, I think that as they are used to dealing with water cooled truck engines and are not correct for our old bikes - particularly at ambient temperatures of 30 + degrees.

I don't think being too lean is the problem, the carb is set up richer than what is stated in the Bacon book.

Yesterday I ran it for about 5 minutes in the garage, it sounded good.

But it's coming apart again, I'll open the sides up to 5 thou per side, leaving a strip about 45mm wide front and back at 4-5 thou total.

Wish me luck !

- Log in to post comments

If the piston is correctly…

If the piston is correctly designed and manufactured, the machine shop should only need to bore accurately to the stated size (or oversize). The proper clearances should be built in to the piston production process. From seeing some reported correspondence with one modern manufacturer, they might not be using the same high silicon low expansion alloy so the clearance they make the piston to will be bigger than (say) Hepolite original. So we probably should expect more piston slap when cold than on a good condition bike with new old stock pistons. Of course it's all very well saying this, but it doesn't explain nipping up if the bore is correct. Do you have accurate bore measuring equipment like a Mercer bore gauge and big micrometer? That might show what's up...such as perhaps an undersized bore.

Alloy pistons of course expand more than iron barrels. The skirt is oval so they have bigger clearance at the sides so that the pressure faces can expand to fit the bore and the skirts can flex enough to make sure they don't jam.

- Log in to post comments

Side clearance.

Hi again Richard,

Still not enough side clearance, you need a good 10 thou on EACH side. The front and rear contact only needs a 30mm wide contact area before gradually increasing outwardly. The attachment shows a BSA B44/50 standard piston and proves how much contact area is required for many thousands of miles.

- Log in to post comments

Side clearance

Thank you Richard and David,

I’ll certainly take off more than 5 thou a side.

As there seems to be no reasonable limit to how much can come off (keeping balance and vibration in mind) and as doing it with a file is labourious, maybe I’ll start carefully with a grind wheel and finish off with a file and water paper (to make it look nice).

Once again, this exercise has shown me to be careful of listening to the advice of “experts” (in this case the engineering shop which told me the clearances were fine). Again, I end up doing the job twice!

Thanks again.

- Log in to post comments

Side Clearance

DO NOT GRIND IT!!!. Take it to a machine shop and get them to set it offset in a 4 jaw chuck and machine 2.5 thou off one side, then reverse it and machine 2.5 thou off the other side. If you grind it you will never get the grit out of the piston. Another way is to use a strip of GLASS PAPER, if you can get it and hold the piston upside down on a bench and rub the glass paper backward and forwards until you have the correct clearance. Measure the clearance with long series thin feeler gauges between the piston and cylinder. Use only .001 or .0015 gauges as they bend, thicker ones do not give a true reading. Under no circumstances use emery paper. Wet and dry is probably OK but glass paper is best.

- Log in to post comments

Could..

.. glass particles not become detached and act in the same way as emery? I had a disaster with glass bead blasting some years ago when I had a Triumph Stag engine ruined by glass particles due to not cleaning a gauze strainer in a rocker cover. The damage had to be seen to be believed.

I would use a file - a bastard to take off the bulk then superfine to restor the finish. Or, as Bill suggests, a machine shop to do the job properly.

- Log in to post comments

Thank you

Thank you Bill and Ian.

Grinding it was only a wild thought in my mind to speed up the process.

I would use waterpaper (wet/dry -the paper used for final finishing off a car paint job, grade 2000 or 3000).

I don't know if this is emery or glass paper.

Another wild idea - what about an oilstone?

(We are getting crude now)

On another subject, remember those abrasion marks on the piston at 45 deg to the front rear plane. I have now seen that they line up almost exactly with the 4 holding down studs. Curious.

Could it be that over tightening the head nuts could have deformed the barrel/cylinder? Surely not.

Photo attached again

The piston was measured with a micrometer, it was 79.6 - 79.62 mm front to back; 79.44 - 79.45 side to side; 79.6 at 45 deg.

The barrel is 79.69 f-b; 79.71 s-s; 79.68 @ 45 deg

So clearances are front - back 3.2 thou; side - side 11 thou (5.5 each side of the piston); 45 deg 3.2 thou (1.6 each side of the piston)

It looks like the clearance at 45 deg is much too little - this agrees with the seize marks. Maybe the side to side relief doesn't go around the piston sides enough.

Any comments please?

- Log in to post comments

Let's have another oil…

Let's have another oil thread! It looks from your numbers that the perimeter of the piston is satisfactorily less than that of the bore. So lubrication failure? Hot spots before properly run in? Oil pump?

- Log in to post comments

.0032"...

... is much too tight in my opinion. At least .005" would be the factory recommendation and I would go for .006". It's radial clearance not perimeter that you are looking at.

The barrel does tend to expand in a "square" shape as the cooling where the long stids pass through is different to the fully-finned areas, and you often see that pattern of pickup.

- Log in to post comments

I'm with Ian....

......leave piston alone and give it .005" clearance at skirt.

- Log in to post comments

What was the target bore…

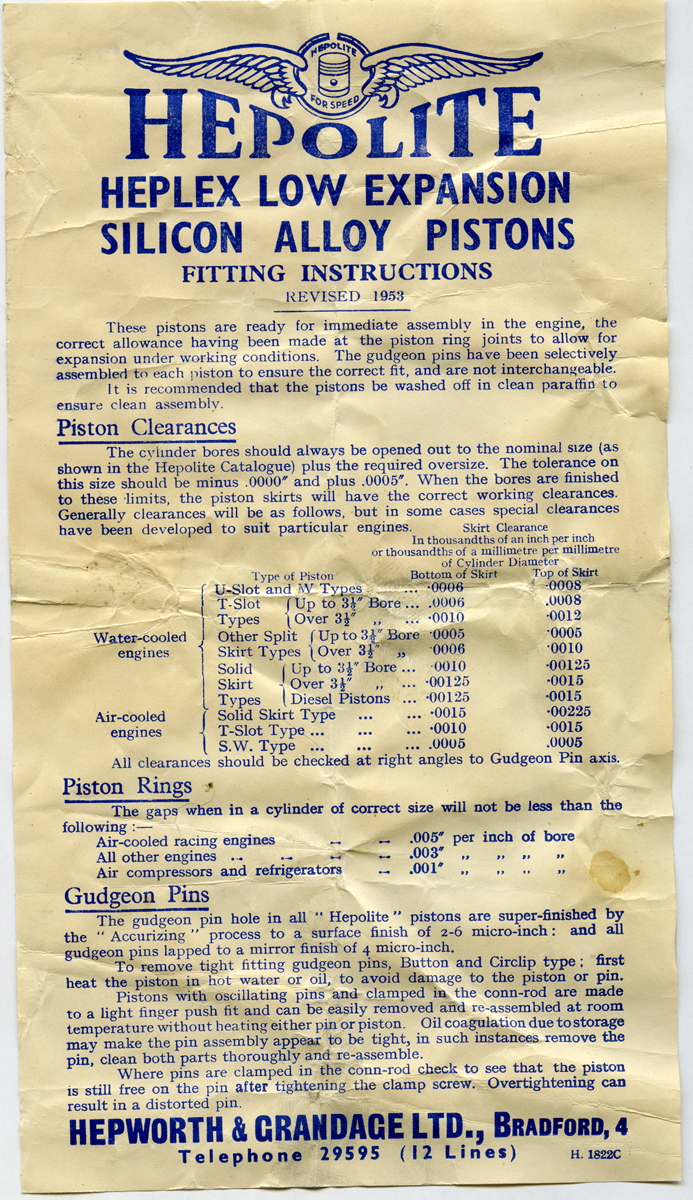

What was the target bore size, and how does it compare with 79.68mm? That is 27 thou over the Norton 79mm, so it is 3 thou undersized if the piston is sold as +30 thou. If your bore measurement is accurate, the problem could be as simple as that. The Heppolite leaflet says the bore should be exactly as nominal size, to within half a thou.

- Log in to post comments

Good point..

.. David. Where was the bore diameter measured? But as I seem to remember it's a rebore it shouldn't (laughs hollowly) vary.

- Log in to post comments

Hullo all

I think the problem is solved - but not yet cured.

Now, having some time over Christmas, I borrowed a micrometer and measured the piston all around, at the bottom.

The results are: F_B - 79.63; @30d - 79.55; @60d - 79.51; @90g (across pin) - 79.45; @120d - 79.52; @150d - 79.62.

As explained to me, the bore should be 79+.030": = 79.75mm. So I should have a F-B gap 79.75-79.63 = 0.12mm = 5 thou. Sounds about right.

BUT the bore is not 79.75, it is 79.70. So the F-B gap is 79.70-79.63 = 0.07mm = 3 thou. Too little.

I'll have the bore honed out by 3 thou giving me about 6 thou.

That should solve it. This confirms what members have been telling me for a while now!

Thank you everybody for your advice,

Have a good New Year.

Richard

- Log in to post comments

1/ Are you using full throttle, and

2/ How many times and how fast are you kicking it over?

3/ Is this hot or cold engine?

All of the above will affect the result you get.

You can check sealing of rings by squirting a bit of oil down the plug hole before fitting the comp gauge. If compression goes up, then ring sealing is poor.

You say newly rebuilt, so has it done enough miles for the rings to bed-in? Also, are the pushrods still free to turn (ie is a valve being held off its seat a tiny amount.)?

Normally, compression figures are quoted for a hot engine, WOT and at a reasonable cranking speed (say 200-300rpm).

Hope this helps, George