I’m trying to remove the half time pinion from the timing side of my Domi 99 but it’s so tight on the crankshaft nose that I can’t slide it off. There’s absolutely no gap behind it so there’s no way of getting even the thinnest bearing puller in there. I can’t be the first person to hit this problem, so what’s the secret behind removing it? I tried putting two screwdrivers between the back of the pinion and that triangular spacer/washer and using them as levers but nothing moved. This one’s got me stumped and is stopping me removing the crankshaft. Hopefully someone can pass on the wisdom to help me sort this problem.

Thanks

Tony

A puller is stocked by …

- Log in to post comments

Hi Robert. Thanks for…

Hi Robert. Thanks for replying. I don’t see how a puller would work because there’s absolutely no gap between the pinion and that triangular plate thing. How does the Norton puller work if it can’t get behind the pinion to pull it off?

thanks again

Tony

- Log in to post comments

Hello again Tony, the puller…

Hello again Tony, the puller is a "special" with three wide legs that have very small flats that engage behind the pinion where the three flats on the pinion washer are positioned. The puller body is rotated to compress the legs on to the washer and then the centre bolt is tightened to pull the pinion along the key and from the crankshaft. Sadly the puller has no other use other than its advertised purpose - however they do look nice and get many comments when left around any workshop. Sorry I have digressed. I have managed to remove the pinion in the past with small tyre levers and small steel wedges but all the other gears, chains, studs and pump must be removed first. It is better to have the intended tool but the pinion is not normally too tight and if the key is in good order they do come off with perseverance. Once it has moved a pair of flat steel bars can be inserted and supported in a vice with the drive-side crankcase removed. The end of the crank is struck with a soft metal mallet and hey presto......... Good luck, Howard

- Log in to post comments

The triangular spacer is…

The triangular spacer is triangular simply because you shall use the three-legged timing pinion extractor. On mine I had to grind the tool a bit on the outside to make it fit.

- Log in to post comments

Puller Problems

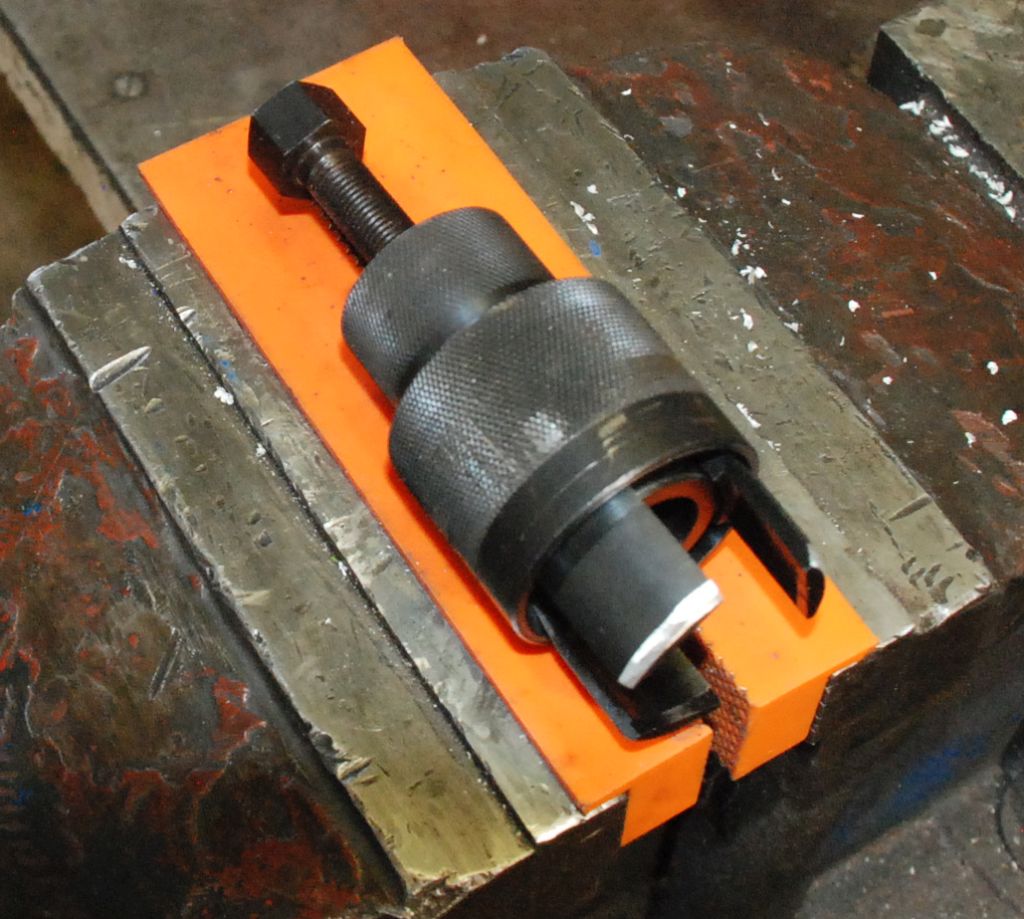

The puller that Robert refers to can be seen in the attached photos. It works by hooking under the pinion. The triangular plate allowing this to happen. However, as can be seen in the photos some of these pullers need a little modification to work correctly otherwise the feet just break due to insufficient points of contact. I retrieved these photos from elsewhere on this Site so a big thankyou to whoever originally posted them.

Finally......Use some means of heating the pinion before trying to extract it off the shaft.

- Log in to post comments

Thanks Michael and Philip. I…

Thanks Michael and Philip. I have one of those 3-legged pullers but it didn’t fit behind the pinion. I guess I need to do a bit of grinding on the feet to get them to fit - thanks for that advice. Heating the pinion is a good idea - I wasn’t sure if it would do anything seeing as the pinion and the crankshaft nose are similar metals -I assumed that they’d both expand by the same amount when the pinion was heated but maybe not. It’s worth a try.

Thanks again to all who replied.

Regards

Tony

- Log in to post comments

Nice pictures Phil. …

Nice pictures Phil. Levering the thing off has been known to fracture the thin alloy behind.The Engine sprocket is the one that can really fox you. The puller currently supplied is about as much use as a chocolate fireguard. The pukka factory tool is the only thing that would shift mine.

- Log in to post comments

half pinion removal

I believe the Domi half time pinion is the same set up as the Electra where the book says a special puller is needed. You can split the crankcase first and then there is lots of room behind the pinion to use a regular puller so that you can get at the main bearing.

- Log in to post comments

Hi. The pinion is off!…

Hi. The pinion is off! Special thanks to Phillip for the photos of how to re-profile the legs of the puller. Once they’d been ground back, they fitted behind the pinion perfectly. I’ve had that puller for over seven years but never managed to get it to work - finally it’s a useful part of my toolkit rather than just an expensive ornament.

The ‘new’ problem is that I still can’t shift the crankshaft out of the timing side crankcase - do I need to apply heat to the crankcase so the the main bearing comes out with the crank or is there a way of getting the crankshaft out while leaving the bearing in the case? One thing I’ve just thought about is that the previous owner might have used Loctite on the bearing inner race - I guess pulling the crankshaft with the bearing attached is the better option if that’s what the previous owner did.

Any views and advice gratefully accepted.

Regards

Tony

- Log in to post comments

Because the bearing is…

Because the bearing is clamped in position by the pinion it does not need to be a tight fit on the shaft. polish the shaft with emery to ease the fit.

- Log in to post comments

He might have had a bearing…

He might have had a bearing outer spinning in the crank case, and used a bearing lock. Heat should soften it. 150C or thereabouts (Loctite web site might assist).

My PO drilled holes for a drift to help to get it out. At least one of my books says "don't drill..." but I don't know why especially...

- Log in to post comments

In theory the heat should…

In theory the heat should work, but bearings are also often too tight on the shafts.On a Ducati I rubbed down the bore of the bearing and its been fine for many years.

- Log in to post comments

A puller is stocked by Norton spares stockists .I bought a Triumph one and modified it a bit. Could try heating it a bit.