Hi fellow Norton friends

I have a query.

Should my 500T have a head gasket or not??

Mine has one and has a really annoying oil leak and starts smoking when hot and was wandering if the head gasket was the cause.

I look forward to you replies and assistance.

For what it's worth

- Log in to post comments

Thanks Ian Hopefully…

Thanks Ian

Hopefully someone here can assist with the alloy cylinder and head. It could well be similar to yours and have no gasket.

- Log in to post comments

cylinder head

I had a new 500 T in 1952 no head gaskets were used. I now have a used one no gasket either. Bryon.

- Log in to post comments

Cylinder Head Joints

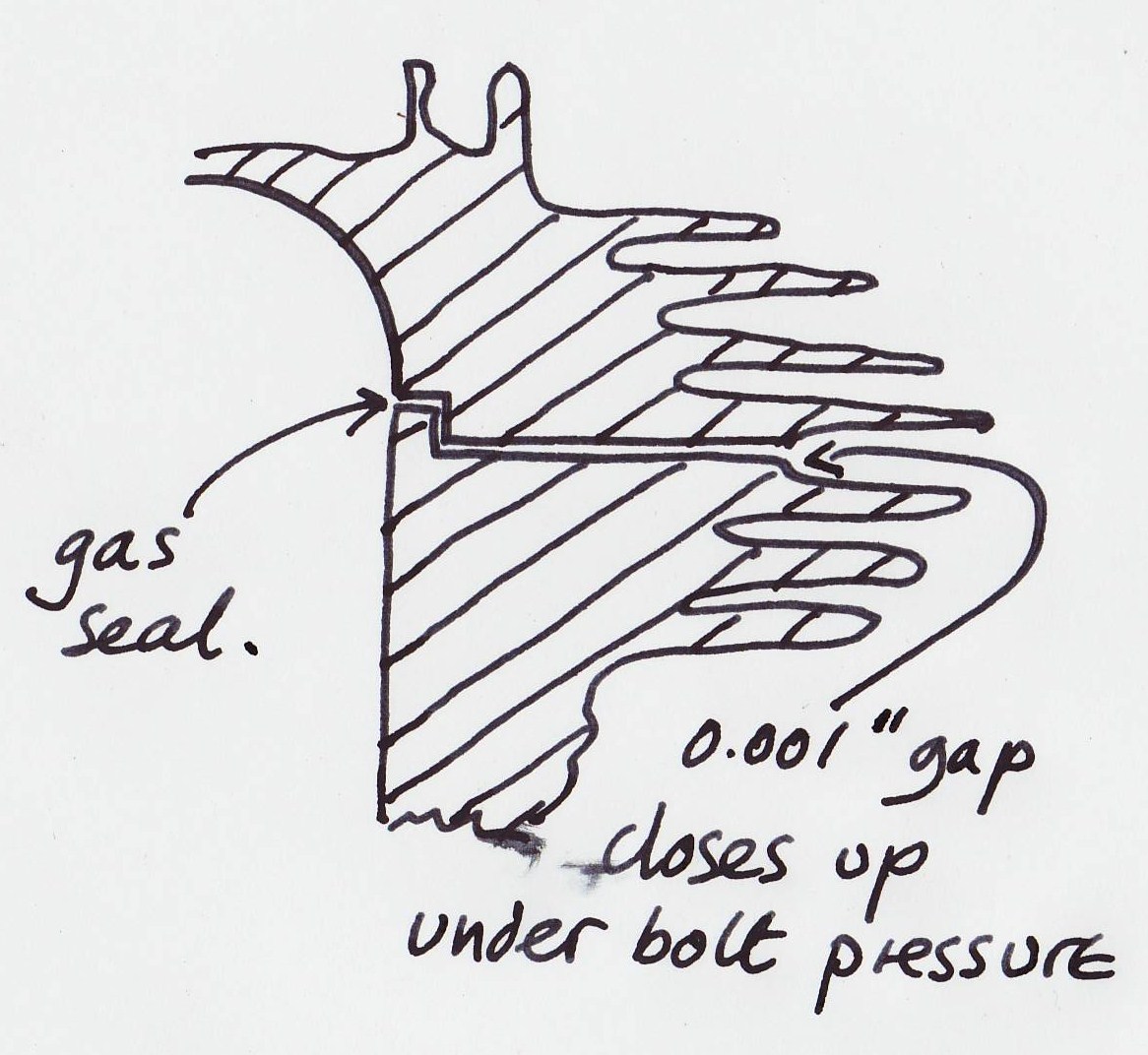

OHV machines usually have an aluminium gasket, I don't know if that applies to 500T. OHC machines rely on a ground joint without gasket. My '56 19S (iron barrel, Alfin head) used to leak oil from the head joint but has since been modified to eliminate the gasket. At the same time shallow pockets were machined in the top face of the barrel to accept o-rings to seal the valve oil drains. These mods cured the oil leaks from the head joint. However, it is not as simple as just leaving out the gasket when the head is refitted. The gas seal should take place on the top of the barrel spigot rather than the broader area around the spigot. For this to work correctly the height of the spigot needs to be around 0.001" taller than the depth of the recess in the head. It may be necessary to skim the head to achieve this, and to correct any distortion of the head that may have occurred over the years. Reproduced below is the advice that the late George Cohen published on his website:

CYLINDER HEAD JOINT

An all the single cylinder engines I have worked on (from an all iron head & barrel twenties OHV to an all alloy sixties DOHC Manx) the same principals and engineering apply.

An all the single cylinder engines I have worked on (from an all iron head & barrel twenties OHV to an all alloy sixties DOHC Manx) the same principals and engineering apply.

There is NEVER a gasket. The idea is known as the “double ground joint”.

The theory is simple, the engineering a little more difficult.

The head joint comprises of two parts; the spigot interface and the wider head barrel joint. Say, the spigot on the barrel is 0.125 inch high, then the recess in the cylinder head needs to be 0.124 inch. This means that the seal is at the spigot joint and the wider joint is to prevent distortion.

The practically, especially on well used alloy top ends is a tad more difficult. If you measure the spigot height on the barrel, it is unlikely to be the same all 360 degrees around. The same applies to the wide surface on the barrel. With frequent and less frequent heating and cooling over 50 years the original manufacturing tolerances have been lost and distortion has taken place. On a fifties Manx engine I worked on last year the barrel, at the wide flat surface was distorted by 0.008 inch and at the spigot, 0.005 inch. The cylinder head was worse, with the wide surface being 0.013inch off flat!

Consequently these defects need to be corrected.

Mounting the barrel in the lathe and truing up and machining is relatively easy, but the cylinder head is more difficult. A special jig has to be made up to allow the truing up to be established. A good medium size lathe, grip true facility, magnetic face plate and some clever thinking is required.

The goal is to obtain a double joint with the spigot of the barrel mating in its recess . For Iron head and barrels, there is rarely any distortion and the easiest way to obtain a good joint is as follows: Hold the cylinder head upside down in the vice (securely but without causing any damage). Put some coarse grinding paste on the broad surface and fine in the spigot recess and add a few drops of thin oil to both. Carefully fit the barrel onto the head and with a anti-clockwise and then clockwise rotating motion, lap the two together. After a few minutes, wash of all the paste and oil and inspect. You should be able to see the lapping on all surfaces. Repeat until a perfect face on both broad surfaces and spigot are established.

Torque Iron set ups to 45 ft/lb and aluminium one to 32 ft/lb. You can use a very slight smear of either a hard setting goop or even a smear of oil or grease, which will burn hard.

Hey Presto, no more oil leaks.

- Log in to post comments

... my 1952 ES2 with iron head has no gasket and had excellent compression (till I took it down to repair a couple of fins, and haven't tried it since). I have refitted it with a tiny smear of Wellseal around the oil drain holes which I suspect are similar to yours, and a similar smear around the cylinder spigot.

But as I say, this is iron head not alloy.