Hello. Just to set the scene I inherited a 1963 88 sport with a 1966 650ss engine. Well a 650ss crank and head with a 99 barrel anyway. See previous posts for the tedious details… We have just done over 300 miles since the rebore and we are firmly in the fettling and running in stage.

When off the pilot she is running well enough but does seem to lack power over 3000 rpm. To be fair I’m not hammering her too hard. After the last run I checked the spark plugs and they were very rich. The needle was on the middle setting but I dropped this down a notch and she is now on the lowest setting for this particular needle.

I took her out again today after changing the needle position and had some issues.

Again, when up at revs she is running well enough but does seem to lack power over 3000 rpm. I’ve been up to 60 a couple of times and she runs nicely at 50 but this is not the issue at the moment.

The issues come at lower revs. Under 1000 rpm she is now very lumpy and cuts out when pulling up to junctions and lights and despite raising the tickover at the roadside she’s not at all happy. The issues come when the clutch is in and I’m braking. The engine just dies and usually in embarrassing situations.

I did have a moment pulling up a hill earlier when clearly there must have been some dirt in the carb as she spluttered and almost stopped. I was able to ride through it and there hasn’t been a repeat of this issue yet. I will be cleaning out the carb imminently to see if I have any debris etc. I was happy the tank was clean but will check. The fuel came from a jerry can and on reflection may have been a bit old. I’ll get a new batch soonest.

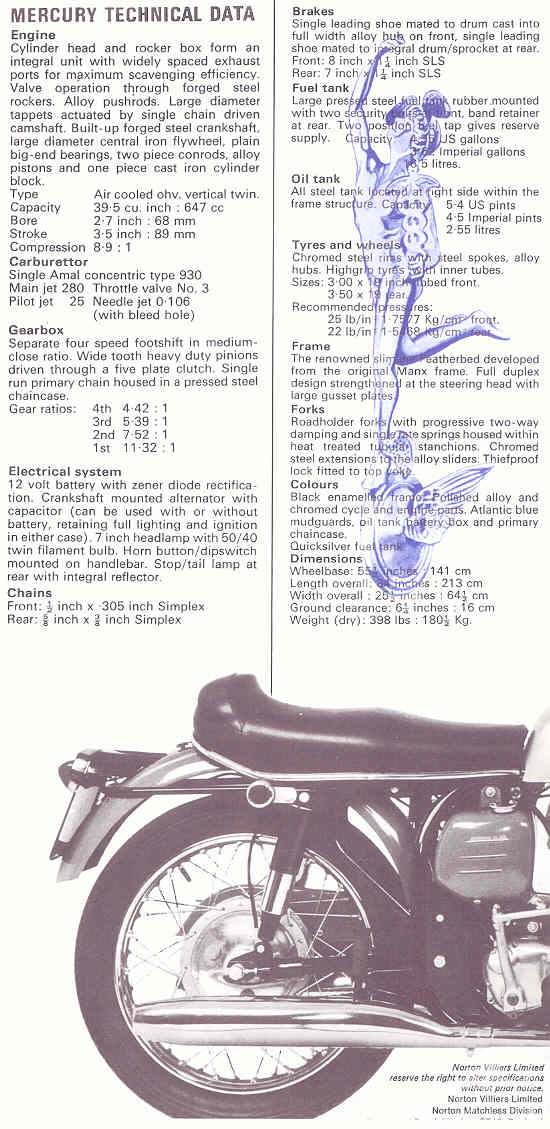

Right from the start this was going to be a single carb bike and I have set her up with a new Premier Concentric 930/28 carb currently running with the recommended settings for the Mercury which seemed a good place to start.

The carb as supplied has a 280 main jet, and a 106 needle jet. This was as supplied new by Burlem/Amal so I didn’t quibble.

On looking into this more closely I can now see that the Service notes say this should be a 270 main jet. The 106 needle jet seems OK but Amal say the carb has a size 17 pilot jet which service notes says should be a 25.

Is the main jet/pilot jet the issue here? Is the difference between pilot jet sizes that significant? It does seem a big gap but I have no frame of reference here. The carb is only a couple of hundred miles old so other than the jetting etc then it can’t be a wear and tear issue.

The manifold was also new so I’m happy there is no air leak in the circuit.

Thoughts on the above gratefully received.

Cheers

Kit

And whilst we are at it

- Log in to post comments

Hello Kit - I see that there…

Hello Kit - I see that there is some confusion here. I too bought a new Mk1 Premier Concentric carb from Burlen some time ago for a Mercury. As you point out they have fitted a new pilot jet (622/502-17 which has two grooves) in place of the bush jet that the original Mk1 Concentric had. The bush had a size that was equivalent to the older jet it replaced and had a part number of 124/026-25. So the new pilot jet in the Premier has a 17 thou internal diameter. The older reference of 25, I am told, is defining the maximum flow rate into the airstream and is probably 2.5 gallons/hour but may be in units of lbs/hour. Sadly it is related to the inlet manifold vacuum and how quickly the pressure increases as more air flows into the engine. I think you should stick with the 17 thou pilot jet but just in case you've blocked a fuel circuit pathway they can be quickly removed and cleaned out. Check that the tiny holes in the bottom run in the neck of the carb are free of debris. One is downstream of the throttle valve and the other is upstream. Use carb cleaner - don't poke a needle down them. Don't overtighten the carb mounting nuts and ensure that you've fitted the paper gaskets to the manifold to head junction and the carb to manifold junction. regards, Howard

- Log in to post comments

Thanks Howard - I'm using a…

Thanks Howard - I'm using a heat insulating gasket between the carb and manifold - do I also need a paper gasket here?

- Log in to post comments

Ah - that makes sense. I'll…

Ah - that makes sense. I'll stick with the pilot jet then. The issues are probably something to do with my set up or dodgy fuel then. What is your pilot jet set on? How many turns out?

- Log in to post comments

Kit - Mine was just about 1…

Kit - Mine was just about 1 1/2 turns. It gave a steady tickover at 800 rpm set by the throttle stop. Have fun but ride safe. You didn't say if you have a magneto or the twin coil system or an electronic version of the coil set-up. Also do you have an air filter ? I'd fit the paper washers as well. Howard

- Log in to post comments

Thanks Howard

Ok. I'll get some paper gaskets. It's a twin coil using Pazon ignition. My air screw was set at 1 1/2 turns as well. I have a screw in AMAL wire air filter.

I've checked the float and needle and all is correctly seated. I am beginning to suspect the fuel was 'off' and dirty which probably won't have helped the overall smooth running. The amount of junk that was in the bottom of the float chamber was a worry.

I'll also fit an inline fuel filter!

cheers

Kit

- Log in to post comments

Carb Specs

Hi Kit.........I have exactly the same set-up as yourself.

i.e. a 650 engine running on a newish single Premier 930 Carb.

My main jet is 270 and I have a K&N mesh filter hanging off the carb end. Otherwise, I would fit a 280 main.

The pilot jet is a 17 which other owners tell me is correct for my engine and carb.

I have covered over 10,000 miles with this Concentric carb and noted several issues right from the beginning.

1) When the carb was new the engine needed full choke to start and catch plus even after several minutes of warming up needed some choke to pull away. That lasted about 3 months.

2) I have three separate filters in my fuel line but the float bowl fills up with black gunge every 1000 miles. If I don't clean it out then the main jet gets blocked. I suspect it is coming from the anodised slide.

3) My pilot screw is 1 3/4 to 2 turns out. It is really difficult to get an even tickover. My Wassell was much better at giving a smooth tickover plus 60+ mpg.

Photo below shows carb rubbish. Note the amount!

- Log in to post comments

Yikes

That's alarming to hear and to see that amount of gunk.

So far I can knock the choke off pretty much as soon as she is running and don't need it after that.

I've cleaned out the old fuel and bought new. There wasn't a lot of debris in the tank or carb filters other than in the float bowl. The tank remains clean and I'm not seeing any rust - it's certainly not reaching the filters anyway.

Once I have a new inline fuel filter I'll report back on how she runs. I wonder why tickover is so difficult? I would have thought having one carb would make this simpler. Puzzled

- Log in to post comments

I'll also try a 270 jet as I…

I'll also try a 270 jet as I have a 280 at the moment and a wire air filter - this might help with the current richness even though the needle is on the lowest setting. Every day is a school day!

- Log in to post comments

One of these - an Amal…

One of these - an Amal threaded cone filter for the 600 series.

- Log in to post comments

Heat insulators

I fit a paper waher between the manifold and head with grease on one side, wellseal on the other. The carb O ring should be enough for the other side. These tufnol insulators have a fairly true flat surface.

- Log in to post comments

15 degrees of tilt?

Just a thought as I wait for the gaskets to arrive - could the 15 degrees downward angle of the 650ss head be causing issues for the carb float? The manifold is a straight item and so the carb is leaning forwards at 15 degrees.

Obviously the carb is not horizontal across the axis of the float bowl, so could that degree of lean cause the float to be open and for the bike to run rich?

I'm pretty clear that the bike is not running lean as both the spark plugs are wet and black.

- Log in to post comments

My old Atlas

I can't see the angle of tilt being an issue. My old Atlas had the standard downdraught head, and the 2 monoblocs were fitted with straight spacers, thus the downdraught was not affected.

Otherwise why did Norton bother developing a downdraught head....

- Log in to post comments

I don't know which single…

I don't know which single carb manifold that you're using on your 650SS head but it doesn't sound like any of the ones that I have used. The ones I have used bring the carb back to an almost horizontal plane. I once saw a Commando manifold used on a Mercury and the carb was uphill but it ran fine. The carb on my Mercury was almost horizontal . It would be possible to mount one such manifold upside down but the carb would be very steep downhill (ie > 25 deg). I did have twin Concentrics on a late 650SS and they were mounted on the parallel alloy spacers (with balance unions) - so they were pointing down at 15 degrees, as you point out, and they were designed to run like that from the factory. Good luck, Howard

- Log in to post comments

Happy Days

I got the manifold from Norvil and so far as I recall there was no option to purchase one with a 15 degree bend!

I'm going to have to go back and see if I missed a trick but I'm starting to wonder if this might be an issue. That lean might throw the float out enough to make it run rich.

- Log in to post comments

For what it's worth....

... the carb on the Electra is similarly tilted down towards the cylinder head. I had a single carb manifold on the Commando and I'm almost sure that was straight, meabing the carb was tilted as well.

I actually think the Concentric is better than the monobloc in this respect as it also doesn't mind side to side tilt.

- Log in to post comments

Mercury carb info

If you can wait a couple of days when I get home I'll be able to look up the Mk1 concentric spec for you. I have an original workshop manual for the Mercury and the only difference from other 650's was a small insert for the carb spec. From memory the 270 main jet is correct and is for no air filter.

I'll also be able to check the original inlet manifold to see if the carb is mounted horizontal or at 15 degrees.

- Log in to post comments

I know but...

Are you quite sure you are running with the choke off - i.e. lever fully back? I have known a couple of riders caught out by this, one very recently.

- Log in to post comments

brass screw

That one you pictured is an ACCESS screw to the pilot jet circuit, so is kept fully screwed in. ( I recently temporarily removed the one on my single carbed Commando 850 MK3, to enable pilot circuit cleaning, for which I had purchased a set of varying cleaning wires and miniature bottle brushes, which worked very well.)

The 650SS was sold with twin downdraught carbs at same angle as yours, and I have never heard of a problem with those.

- Log in to post comments

I did have a few instances…

I did have a few instances early on where the lever wound down after a few miles. It's screwed down really tight and stiff now, and I keep checking, so I'm pretty sure that's not happening - but good shout.

- Log in to post comments

Since getting her back…

Since getting her back together she has always had an air filter - but then again it looks like she's always been running rich. One more thing to try when I reassemble her I guess. I know they weren't supposed to have filters but surely this isn't a good idea??

- Log in to post comments

Trying it without the filter…

Trying it without the filter is a test, to see if the filter is restrictive. It certainly isn't very big.

- Log in to post comments

I see complaints by Commando…

I see complaints by Commando owners that the available single carb manifolds seriously reduce power at higher rpm.

I've no personal experience.

- Log in to post comments

Thanks Phil

That's really useful info. My carb is pretty much on spec. On a side note I cannot see a single picture of a Mercury that doesn't have the carb tilted at 15 degrees or any with an air filter so this has to be the standard set up.

I will try her this afternoon with no air filter and see how we go. Thanks again.

- Log in to post comments

Sitrep

Ok - I refitted the carb - without air filter and with fresh fuel into the clean tank. Started nicely - no choke needed. Choke is screwed down tight in fact and definitely no on. Just to remind everyone - the needle is on the lowest setting at present. Premier 930/28 single carb with a .106 needle.

I allowed her to warm up and then tried to adjust the tickover. Very lumpy indeed. Exhaust is noticeably rich and very smelly - even her indoors complained/commented on this. I've had to stop as the fumes are really strong even with both doors open in the shed.

I cleaned and checked the spark plugs beforehand so the gap is good. Something fundamental is wrong here. I now have a headache.

- Log in to post comments

Is the pilot jet....

... firmly screwed in and its cap on tight with a fibre washer? A loose jet can let too much fuel through.

- Log in to post comments

Yes. Happy to confirm that's…

Yes. Happy to confirm that's the case. It's a brand new carb so everything is pretty well sorted and clean/tight etc.

- Log in to post comments

Skimming through the thread…

Skimming through the thread again, have you not checked the fuel level in the float bowl?

- Log in to post comments

Ian - wrong type of jet and…

Ian - wrong type of jet and carb - it's a Premier Concentric on Kit's bike. Kit - It sounds to me as if the fuel level is incorrect. It's possible to rig up a small piece of clear tubing on to a banjo and fix it to the float chamber at the bottom float chamber plug. I'm sorry I don't know what the plug thread is but you will probably have to get a longer one. Steve at Burlen will know and no doubt assist you. Ensure that the float cut-off needle tip is not damaged and it sits firm into the valve. During your investigations you haven't misplaced the volume screw neoprene washer that seals the screw ? Similarly there is a washer on the pilot jet. Good luck, Howard

- Log in to post comments

Ah, sorry - missed that.

Must learn to read carefully!

I have the Wassell evolution which is a close copy of the Premier and it seems to be well made.

- Log in to post comments

Float level?

Hi Kit,

Whilst having no personal experience of concentric carbs on a Norton, I do wonder if being the 'Premier' carb, they come fitted with a 'stay up' float in them?

I have had issues with these physically binding on my monobloc carb thus making the bike run very rich. The temporary fix for me was a 2nd gasket for the float chamber cover allowing the float to move and do it's job, but that isn't likely to help you

I understand that others have had similar issues with stay ups in concetrics, but I have no info on how it was cured.

Just because the carb is new, doesn't mean it was set correctly.

Anyone know where the fuel level should be on a concentric? At least it is adjustable with the new floats.

Regards, George

- Log in to post comments

The drain plug head on my…

The drain plug head on my non-Premier Concentrics is 9/16" x 26 tpi Cycle.

You can drill a drain plug or a Monoblock main jet cover and jam a clear hose into it.

Can probably lash up a banjo fitting to the bottom of the bowl with washers too.

- Log in to post comments

Sinking not floating!

I did check that the float (a new stay up float) was at the correct height as per the Amal Technical data from their website. I did this by eye and even with the bowl tilted forward 15 degrees this didn't seem to be an issue.

The correct fuel level for all Mark 1 Concentric carburetters is 0.21" plus or minus 0.040" below the top edge of the float bowl. Thus when the needle valve is being held shut by the tangs of the float, the level of the fuel will be between 0.17" to 0.24" (4.33mm to 6.35mm) from the top of the bowl.

If this persists then I'll try with the bowl off the carb and using fuel to test as suggested. What fun!

- Log in to post comments

If far to rich on idle, you…

If far to rich on idle, you must have something very wrong with pilot screw. It sounds like it must be screwed much to tightly in. An approximate start point should be 1.5 turns out. Have you confirmed this?

Air filter, slide, main jet, cutaway, needle and needle jet all irrelevant at idle.

Some say float can stick on its own gasket.

Also some havd allegedly found swarf inside. If it won't work you should send it back

- Log in to post comments

Thanks David - I can conform…

Thanks David - I can conform the start point for the pilot jet is 1.5 turns out. This gets reset for each of my tests or changes. The o ring is present and correct. As others have said this is clearly a pilot circuit thing and not a needle jet issue. I'll be testing the float properly this afternoon - off the bike and with some petrol - weather is forecast to be lousy anyway.

- Log in to post comments

"That's not 1/4" below top…

"That's not 1/4" below top of float bowl!"

See how easy it is to check.

- Log in to post comments

Updates

Ok - the float does what it should and when it should when at 90 degrees to horizontal. (See pic 1) with just under 5 mm of gap.

When tilted forwards at 15 degrees (see previous comments) to mimic the position on the bike, petrol does spill over the edge of the bowl for a while before the float kicks in. The additional angle of lean does bring the float higher and halves the gap to about 2.5 mm. I'm thinking it might be sensible to adjust the tangs (as described in the Amal tech notes) to prevent this overflow. Any thoughts?

As the carb was off the bike I took an opportunity to blow through all the pilot tubes with compressed air. All good and clean. Pilot jet is well seated.

- Log in to post comments

Final Update - Thanks

I had a decent run out today and it seems that the combination of dropping the needle to the lowest position, removing the air filter and adjusting the tab on the float has improved matters considerably. The bike is pulling better over about 3000 rpm and is not bogging down at lower revs. The tickover is possibly a bit fast (1000 rpm) but she will sit happily in neutral at a traffic light without complaint.

I would still like to refit the air filter at some point so will investigate a 270 jet as suggested by Mr Hannam above.

Thanks for all the help, education and support. I declare this thread closed!

- Log in to post comments

I'm checking my carb - very clean - some gunk in the float drain cap and a small speck in the banjo filter. What is this screw? Not mentioned in my 'hints and tips for the Mk1' leaflet provided by Amal. I assume it's access for the pilot jet? Does it have a tuning function or does it stay closed.

Ignorance is bliss until it's a worry!