Has anyone fitted a MK3 hydraulic primary chain tensioner in their Pre MK3 cases?

And whilst on the subject of hydraulic tensioners I see that at least two camchain tensioners were developed but can't find any for sale?

I've never heard of anybody…

- Log in to post comments

why would you

Mk3 method of chain tension is no improvement, have seen a few examples of primary chains nibbling away at inside of chaincase, requiring a new chain. Old chain perfectly serviceable to fit to pre mk3 bike. Norton went to trouble of incorporating universal joint into mk3 cross shaft, pity they did not machine chaincase and gearbox cradle to allow traditional method of tensioning by moving gearbox back. However do remember tensioner on top of gearbox is there to stop final drive chain from pulling gearbox back and over stressing primary.

With regards cam chain tensioner, original version is very durable and in my limited ( 35 years) of riding various commandos needs little attention, rubber faced versions may have an advantage.

If you really want an automatic tensioner, try Norvil as it is still listed as an option if you have an engine built by them.

Choice is yours, as I tell my son, your money you decide what to spend it on!

Regards Martin.

- Log in to post comments

The Mk3 doesn't have a…

The Mk3 doesn't have a universal joint in its cross shaft. It has a splined sleeve to connect the gearbox to the shaft.

According to Andy Forsdyke (the chainman) No one makes decent triplex chain anymore, hence his recommendation to fit Iwis duplex chain to commando primarys.

Granted a worn primary chain will touch the inside of the case, My Mk3 shows where this has happened, the chain was worn out and the rollers had started to break up, There again it was a forty year old Reynolds chain that had seen better days. New Iwis duplex chain fitted at 52k miles in 2014. Still good today at 83K miles

- Log in to post comments

Why? I'm building a bike…

Why? I'm building a bike with MK2A engine,box and primary drive but I have a N.O.S. MK3 cradle so I will have to make some sort of primary chain adjuster. I have seen a Harley part used to do this but as the MK3 adjuster does it's work all by itself I thought would be ideal.

- Log in to post comments

Why not simply slot the Mk3…

Why not simply slot the Mk3 cradle as per the earlier models and fit the earlier gearbox adjuster? You will still have the Mk3 cradle benefit of the secure swinging arm spindle (with cotter pins) and avoid the complexity of trying to adapt the Mk2 chaincase to fit the Mk3 tensioner, which does not seem feasible anyway..

- Log in to post comments

I don't think slotting the…

I don't think slotting the cradle is a good idea, Tensioning the primary means adjusting the rear chain having to ensure that the gearbox is in line and I'd be able to fit a proper oil seal behind the clutch.

- Log in to post comments

Comparing the Mk3 primary…

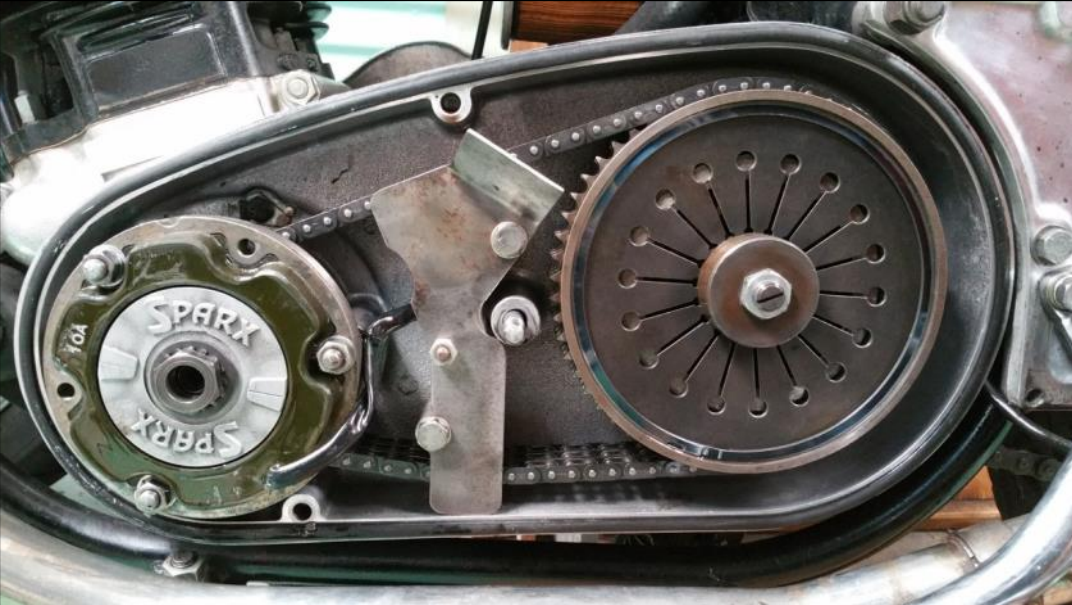

Comparing the Mk3 primary case to the earlier primary case, the Hydraulic tensioner position would obstruct the chaincase center stud (and the casting that contains this stud) that fastens the outer cover on the earlier case.

You are still going to have to drill a hole in the Mk3 gearbox cradle to mount this chaincase center stud as it is in a different position between the Mk3 and earlier cradles.

- Log in to post comments

2 adjusters, one on each side.

You could consider to slot the Mk3 cradle and make/fit an additional adjuster on the primary side.

The Mk2 seal in my view is good enough for the job.

- Log in to post comments

https://www.youtube.com…

https://www.youtube.com/shorts/5dAj22zT65U

"Uses a reciprocating hydraulic tensioner from a 1975 Mk3 Norton Commando. 500ml of Type F ATF primes and replenishes the tensioner reservoir (excess visible in the video). The 'level plug' is now a 'drain plug' as a 'minimum level' indicator is required. The ATF also lubricates and cools the primary chain and clutch centre bearing. The clutch plates are full width sintered bronze (eccentric circle type) and polished steel. The primary cases required additional sealing & breathing to prevent ATF loss in use."

- Log in to post comments

Owen Greenfield

Martin, the video relates to this neat conversion done by Owen Greenfield of Australia.

More info here from the Energette, the club magazine of the Norton Motorcycle Club of South Australia.

He also fitted a proper seal behind the clutch, there is a video of that somewhere on his youtube channel. This to keep the ATF inside.

- Log in to post comments

That's perfect Bennie -…

That's perfect Bennie - Thank you.

Now - anyone have a MK3 chain adjuster they don't use?

- Log in to post comments

I've never heard of anybody fitting a Mk3 primary hydraulic tensioner to a pre mk3 case.

Cam chain tensioner wise, the hydraulic/springloaded/wedge type versions that were developed (by others) didn't prove any good. Hence none for sale.

Fit a rubber pad Mk3 type, fit and (almost) forget.