Hi all - I am looking for input / advice on whether to add insulating washers under the inlet side valve springs as originally they were only installed on the exhaust side . I am rebuilding my cylinder head with all new components from Andover with the exception of the rockers and their spindles as those were in fine condition. Subject head is June 1972 manufacture 750 Combat Roadster . SN 209xxx - head stamped with C under head steady - "M" or "W" ( depends on which way round you read them ) stamped on small flats by exhaust ports.

I understand these were added to to inlet side on later models -850 perhaps ? - Would it be beneficial to add them , and if added is there potential for inducing coil binding in the springs by adding to the stack ? I really don't want to assemble everything and manually turn the engine over to see if any travel is left in the spring column only to have to take it to bits again to remove the washers if they are problematic . Thanks in advance for any and all comment .

Cheers - Richard

Exhaust side only

- Log in to post comments

Thanks Andy - I would be…

Thanks Andy - I would be interested in reading that bulletin so please do post it if you can

Richard

- Log in to post comments

Heat insulators for Combat valves - the plot thickens

Richard

As is often the case not as straightforward as I first thought - that will teach me (again) to rely on my memory!

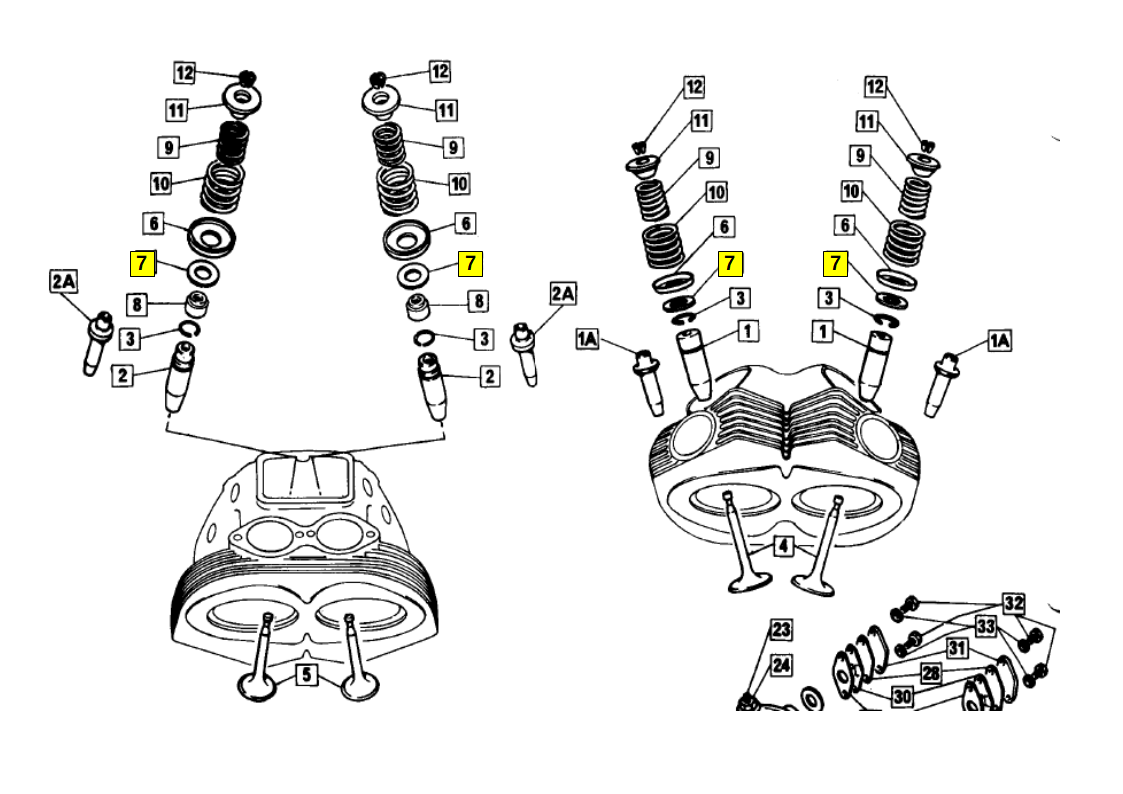

This is from the 1972 parts list.

Ok so far.

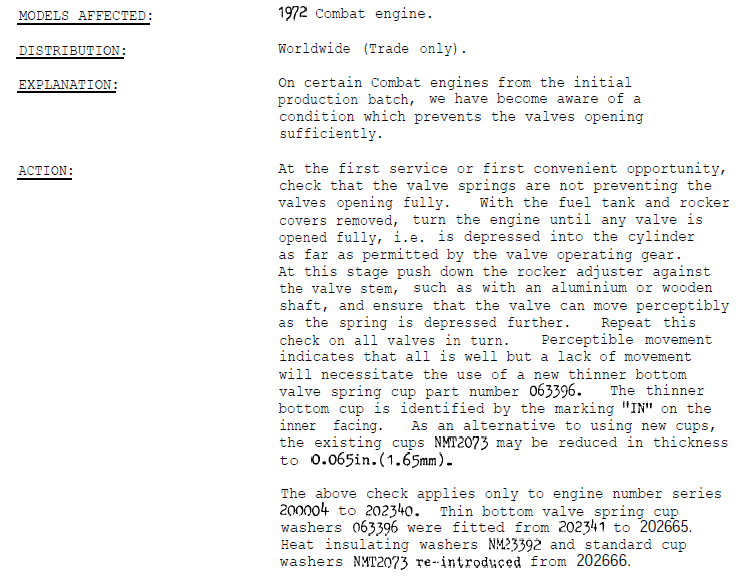

Then from the service sheets (it's number 3 in series 2) see www.eurooldtimers.com/functions/get_file_manualy.php?id=3506

This issue is also covered in the INOA Tech Digest (pages 1-7 & 1-8).

So with your engine being in the 209xxx range and assuming all parts are standard then this service sheet would indicate that insulators can be applied to all valves on later Combat engines.

Adding the insulators to the inlet valves will almost certainly improve spring life.

It's your decision and if you do fit insulators to the inlet valves then I'd definitely do the check suggested in the service sheet for peace of mind.

Andy

- Log in to post comments

RH10 Head

Hi Gordon

Whatever worked for you...but...for an 850 MkII with an RH10 cylinder head and standard valve parts, insulators would have been fitted to inlet and exhaust valve spring seats at the factory.

This from parts list ref 065034 which covers late 750 (after 212278) and 850 up to MkII:

'7' is heat insulator NM23392. From the earlier post it looks like the insulators were only left off the inlet valve spring seats for a range of 750 Combat engines as 'standard'.

Andy

- Log in to post comments

Hi Andy, yes I agree with…

Hi Andy,

yes I agree with your point and that's what made me try and fit inlet valve insulators.

But sorry I've owned my 850 MkII from new and can assure you that Inlet valve insulators were not factory fitted to my machine.

Another anomaly to report is that when I first opened the gearbox for overhaul I found the sleeve gear fitted with three bronze bushes rather than two as per UK parts list.

My Commando Roadster is a 1974 USA export model, maybe the spec differs from UK models?

- Log in to post comments

Be careful

It is still not necessary to fit insulators under the inlet valve spring cup.

The insulators were most probably added to the combat to cheaply and easily increase the spring pressure and thus the spring pressure at full lift to suit the 2S new cam - it failed, as can be seen from the Service Release they went coil bound.

On the MK3, if you fit insulators under the inlets, then check for coil bound, again, it was a cock up here also. the MK3 originally had the Polydyne cam, but then went back over to the 'standard cam' 06.1084, this was never updated in the parts book.

Having in the past worked out the tolerance allowance on the MK3 from the crankcase face, barrel and cylinder head if the tolerances are against you it is possible in worst case to erode any spare capacity you think you have from being coil bound, even with standard items.

The reason it is not required to fit insulators under the inlets is that this part of the head does not get as hot as the exhaust side, and the standard spring rate I consider myself is way to high. The figures used were designed in preparation for the 650 in 1959 and for some reason stayed in place until the end of Commando production.

I run a cam with 10.5mm lift on the lobe, modified valve stems and a Full Auto head, it was found the valve pockets were machined deeper than expected so the fitted seat pressure was calculated at 59lbs with the modified valve stems - the doomsters said it would lead to valve seat recession and fail, after 9,000 miles there is no recession and no failure and the valve stem tips are just like the day they were installed. From what I can remember standard is around is around 100-104lbs.seated from the original drg.

I also removed the insulators from under the exhaust side also, and again have no issues. On the Commando the oil most probably conducts heat past the insulator anyway, as the drain hole is at the side not at the front.

- Log in to post comments

Thank you gents for the…

Thank you gents for the comprehensive and prompt replies . Very timely as I plan to reassemble the head this weekend. It seems that prudence would dictate that I leave the insulators out of the Inlet side so that is what I'll do .

- Log in to post comments

Hi Richard

Definitely exhaust side only on Combat. There is a Norton service bulletin on this.

I'll dig out a copy later.

Andy