So, please will any purists read no further......On my 88 Cafe racer / track bike I have decided to fit a one-way valve to stop the never-ending flow of oil into the sump when the bike is stationary for even a short period. I have fitted a Velo Venom one-way valve into the feed pipe between the oil tank and the crankcase oil input. I replaced the spring and ball from a very reputable Velo spares source before fitment. For those of you not familiar with the Venom the valve is essentially a filter cage affixed to a plated brass body containing a light spring pressing against a ball about 10mm diameter. The output of the valve is from a standard 1/4 BSP pipe thread. On one occasion at Donington Park Mick Hemmings had said to me that the inspiration for his one-way valve was from the Velo design. So with the feed nut undone there is no oil flow. Tick. When the feed nut is done up and I kick the kickstarter with the plugs removed there is still no oil flow but an odd squirt noise from the oil tank suggests that the scavenge side of the pump has attempted to pump. I have used an oil can to prime the feed pipe but that disappears as I kick her over. So my dilemma is this - Does the panel think that an SS oil pump will produce enough suck using the kickstarter to release the valve ? Has anybody experience of using a Velo valve on a Dommie for this purpose ? I may try using a rolling starter to get the revs a bit higher to see if the oil flows but obviously I don't want to run the donk until I know that the oil is present. Kind regards, Howard

If it wet sumps that quickly…

- Log in to post comments

I was going to say thanks…

I was going to say thanks Peter - however I wasn't asking for comments just assistance. I don't want a debate about the wisdom of fitting a valve - just whether or not the SS oil pump will open the valve. Otherwise regards, Howard

- Log in to post comments

Wow, chill out Howard. Doesn…

Wow, chill out Howard. Doesn't get around the fact your oil pump is worn. Will it open that valve just kicking it? No. Service the pump properly, then maybe.

- Log in to post comments

For what its worth

Hi Howard,

When my 650 began wet sumping at a more than acceptable rate, I fitted an RGM supplied 'Velo' type valve on the inlet line. This worked 'perfectly', in that I no longer had a wet sumping issue.

However, the nagging doubts of the naysayers made me change to a switch with an ignition cut out on it instead. I kept it fitted even after the oil pump was "serviced".

Since fitted, I have a lot more confidence that all is ok on the oil supply side.

So, yes the oil pump on a twin will operate a velo valve quite happily, but as Peter says, it is better to fix the root cause of the problem first.

Regards,

George

- Log in to post comments

priming pipes

You say you have primed the feed pipe: but upstream of the valve or downstream? Downstream ( between valve and engine, obviously) is vital, as on instructions with the valve I got from Mick Hemmings in 2002 for my Commando 850.

When I overhauled the bike in 2024, after a 21 year lay up, I took the valve apart to check it, and it was perfect and oily and not stuck etc.

- Log in to post comments

The commando pump runs at…

The commando pump runs at twice the speed of the earlier models. It also has wider pump gears so it will pump over twice as much oil for the same engine speed. That means it has over twice as much 'suck' as the earlier pumps. The result is any comparisons between the ability of these pumps to open a sprung loaded ball valve is not relevant, especially when worn.

- Log in to post comments

Have you tested it to make…

Have you tested it to make sure it does flow? A small magnet should probably pull the ball away and let oil flow.

It does take time for oil to return of course

I'd temporarily replace the tube below the valve with clear plastic. Then you'll see for sure if it's working. It probably won't do for a long term fix because it's likely to be too soft and might get sucked flat.

- Log in to post comments

Thanks to all - George is…

Thanks to all - George is your 650 engine number after 116372 ? If so it will have had the 6-start oil pump gear from new. If not you may have fitted the 6-start gear instead of the usual 3-start. On my 650s and 750s I always preferred the six-start gear but as far as I remember the 500 never got the six-start mod. The original 3-start pump historically is good for about 12 gph at 6500 rpm at 90 deg C, with approx 11.5 gph passing through the crankshaft. When the 650 engine, with the bigger journal size, was introduced the "S" pump was introduced to deliver more than the 12gph to the crankshaft. With pressure fed rocker gear and holes in con-rods, that came subsequently, the 6-start gear was introduced. This upped the flow rate to 25.5 gph at 6500rpm and 90deg C. I consider that Norton thought this was too much so the 88SS stuck with the "S" pump with a 3-start gear. With 13 gph passing through the relief valve on a 650 it makes no sense overloading a 500 with too great an oil flow. David, I did try the magnet trick against the valve's brass body but kicking like mad with the sump plug removed did not show so much as a dribble. As I said earlier I did get a squirt noise from the return pipe in the oi tank. I wonder if removing the sump plug has upset the pressure in the cases and that may effect the flow feed ? I like the idea of the clear pipe. Jan , I did prime the pipe between the valve and the engine feed to the manifold. I may temporarily fit a 6-start gear to see if it opens the valve . Regards, Howard

- Log in to post comments

If you do remove the pump to…

If you do remove the pump to fit the six start gear you might as well service it at the same time.

I would if it was my engine. A quick test when you do get the pump off, before it gets dismantled, clean it by running some paraffin through it to wash the oil out. Hold it up to a light source and look through the oil pump bush (feed outlet) in worn pumps you can see the light around the feed gears, If you see the light, its definitely worn.

You said 'I wonder if removing the sump plug has upset the pressure in the cases and that may effect the flow feed ? '

Answer. No, That will have no effect whatsoever.

- Log in to post comments

3 start

Hi Howard,

I'm running 3 start gears on mine. I have the original scavenge fed rockers, removing much (all?) of the need for 6-start cogs.

My engine is a mongrel, so engine number isn't any use as a guide as to what should be inside it!

The pump is one of those with wider gears inside it though.

Hope this helps,

George

- Log in to post comments

Lateral Thinking

A couple of points re causes of falling oil levels.

Dominator engine parts made from Aluminium alloy were well know for being porous. The main problem being the coarse molecular blend of metals used for these castings..

Any sections that were badly cast or machined too thin were prone to leaking. In cylinder heads this was primarily near the inlet tunnels and in the crankcases the walls of the oil pump and associated tunnels.

The face used to mate the oil pump face was also prone to distortion thanks to the cast iron pump and flexing of the nearly main bearing housing. This being one of the reasons, on later twin engines, a paper gasket behind the oil pump became standard.

- Log in to post comments

David - I did try the magnet…

David - I did try the magnet pulling the ball again using an alternator rotor without success. When I removed the spring the magnet could draw the ball along the valve body quite easily but with the spring fitted the magnet seems unable to move the ball. With a piece of plastic pipe connected to the output of the valve I can suck to release the ball easily and the ball returns as soon as I release the suck ....... Tomorrow I'll remove the pump and fit a 6-start gear and try the procedure all over again. I hope that I haven't got an internal leak in one of the cast-in routes, as Phil suggests but that's the trouble when you race them - they can break. Cheers for now, Howard

- Log in to post comments

A pressure gauge would tell…

A pressure gauge would tell you if the oil is getting to the pump.

You could fit one in place of the pressure relief valve temporarily and just run it at tickover?

- Log in to post comments

Found this...

...while researching my Roadholder article about stopping wet-sumping on the lightweight.

From an American site, I think. Intended for heavyweight engine. What caught my eye was the ball valve in the timing cover modification, looks like a neat, straightforward job. It puts the valve exactly where it should be, downstream of the pump.

Anyone tried it?

Not so sure about the oil pump modifications, should not be needed if the pump is in good condition.

- Log in to post comments

Morning JohnUpstream of the…

Morning John

Upstream of the pump is back to the tank, The ball valve mod you mention is downstream, like the 850 Mk3.

What people don't realise when they fit one of these sprung ball valves in the supply from the tank is they are putting a restriction in the oil supply, a restriction that the pump has to overcome to get the oil it needs. Howard has proved his ball valve opens when he sucked it open, did it stay open then when he stopped providing the suck? No. The spring shut it again. That means the pump has to provide the 'suck' constantly so as to keep the ball off its seat and open. Providing that 'suck' degrades the pumps performance.

In practical terms, All things being equal, Comparing a system fitted with a ball valve in the supply line to one that hasn't. The one that hasn't got the ball valve will supply more oil.

In Howards case, His pump is worn, and he might have an air leak in the supply pipe. This doesn't need to be obvious, a tiny little leak can have a big effect in destroying any 'prime' the pump is trying to acheive.

Fit a valve that has a ignition cutout. Stops wet sumping and more importantly doesn't restrict the oil supply.

- Log in to post comments

John - Please can you re…

John - Please can you re-visit this drawing included. I seem to be unable to read the bottom of the page. It is just a single page ? is that correct ? Howard

- Log in to post comments

Website for valve drawing

Howard, the drawing came from here;

dynodave Atlantic Green Technical Services

Look down the list for Oil/Lube and follow the link.

What I posted is what you get, there does appear to be another line of text, its dropped off the bottom of the page, unfortunately.

The drawing raises more questions than it answers. Where, exactly, does the ball seat? Is it fail safe? What stops the ball moving down the oil way?

This sort of project piques my interest, if I had a timing cover .....

- Log in to post comments

Ooops!

Thanks Peter, edited accordingly to reflect what I meant to say.

I disagree that fitting a ball valve either before or after the pump will cause a restriction. I say this with one proviso; the valve must be designed properly. Looking at the Velocette NRV, as that seems to be the inspiration for owners using this type of valve, the cross-sectional area through the valve is (much) greater than that of the various fittings elsewhere on the pipe. Also important is the ratio of ball diameter to seat diameter. If the design is done properly there will be no restriction to flow and the oil pump will not notice the presence of the valve.

Point taken on losing the "prime". But, does that really stop the pump sucking oil from the tank? My experience with Velo's says no, as long as the last bit of the oil way to the pump is "uphill" and doesn't drain, the pump will have some oil to work with and get the ball off the seat.

Getting this thread back on track, I would advise the OP, if he has the resources, to fit a valve as described in the attachment in my first post. If not, use one of the proprietary "fit and forget" ball valves. I would not recommend a Velo valve in this instance, because the ball is not properly guided. It is lifted on to its seating by a feeble spring that relies on the valve being (near) vertical to work properly.

Going back to Velo's, a Yamaha NRV for, I think, an outboard motor fuel system, is much favoured as a replacement to the original NRV. I'll try and find the details if anyone is interested,

- Log in to post comments

Thanks John - that's a very…

Thanks John - that's a very interesting point about the Velo NRV. My 88 has the 1 gallon International 500 oil tank with the feed at the bottom vertically downwards. I am using an AMC gearbox and there isn't room to fit the valve, at the tank feed, above the box. So I have fitted a 90 degree bend at the output of the tank followed by a brass spacer that covers the Velo filter part of the valve. So the valve is really horizontal - which you suggest is a no no. I will certainly try to get hold of the Yamaha part you mention, if you can get me the details. Hopefully it will fit in the space between the tank and the gearbox. You can e-mail me through the NOC if you would rather . Many thanks to all contributors. I have routed out a pair of 6-start gears but damaged the timing cover gasket when I removed it - so there will be a slight delay. Regards, Howard

- Log in to post comments

Yamaha valve

Howard, here are the details of the Yamaha NRV, I think they cost around £25.

I have never used one so cannot recommend it. But, I know Velo owners who have used them with success. If I could not get my Velo to stop wet-sumping with the standard arrangement I would use it! Having said that, I have made and fitted a valve downstream (thanks Peter!) from the pump, like they originally were.

I would mount it vertically to make priming easier. Some Velo owners like to mount them horizontally under the gearbox to hide it, must be difficult to prime in that position?

- Log in to post comments

I put one of those....

.. Yamaha valves on my ES2 and it worked very well. Of course the advice re ensuring that the oil line downstream of the valve is full of oil is essential. The bike came to me with a manual valve but I was never sure I'd opened it.....

- Log in to post comments

Thanks Ian - I have sent for…

Thanks Ian - I have sent for one of the Yamaha NRVs. I'll keep everybody posted when I run it. Thanks to all contributors. Regards, Howard

- Log in to post comments

Just an update for all…

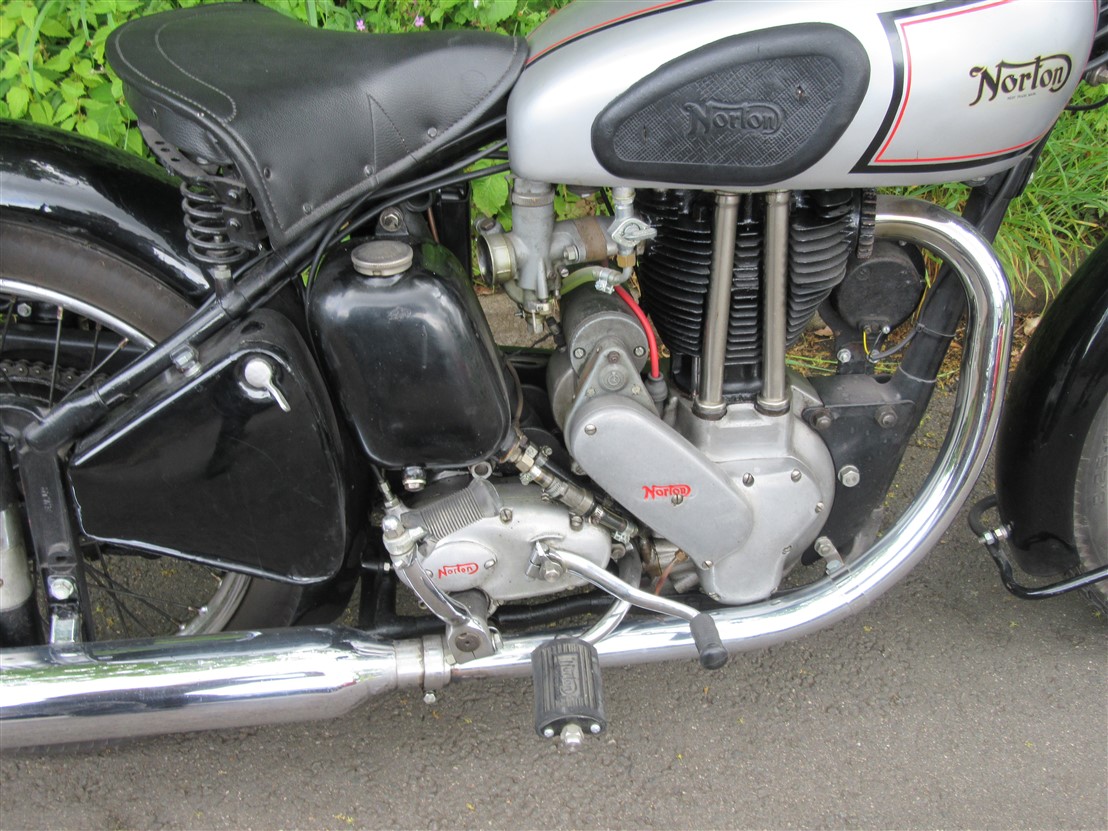

Just an update for all contributors. The attached jpeg file image in my message on the 12 August shows my Inter 1 gallon oil tank with the connections to my Velo one-way valve etc. I have now fitted the Yamaha fuel check valve after consulting with some of you and a close friend in the Velo owners club. The valve chosen is the one in the image from John Crocker previously. I managed to get one from Fowlers in Bristol. I also fitted a length of clear oil hose in the feed line to the engine. I completed the installation today and am happy to report that oil flows as I kick over the engine (with the plugs removed) and oil does not flow with the engine stationary. I shall get the donk fired up in the coming days and report back to you all. Many thanks, Howard

- Log in to post comments

If it wet sumps that quickly, the oil pump needs servicing and the clearances closed up. Probably why the pump can't prime itself. (even though you say you have primed the feed pipe) Why fit one of these things? You will be forever wondering if it has stuck shut.

The only form of 'oil tap' i would condone is one of the magneto/ignition cutout variety. I know Norman White had a rider on his invoices that said that if any form of oil tap was fitted to the engines he had done for customers his guarantee was invalidated.