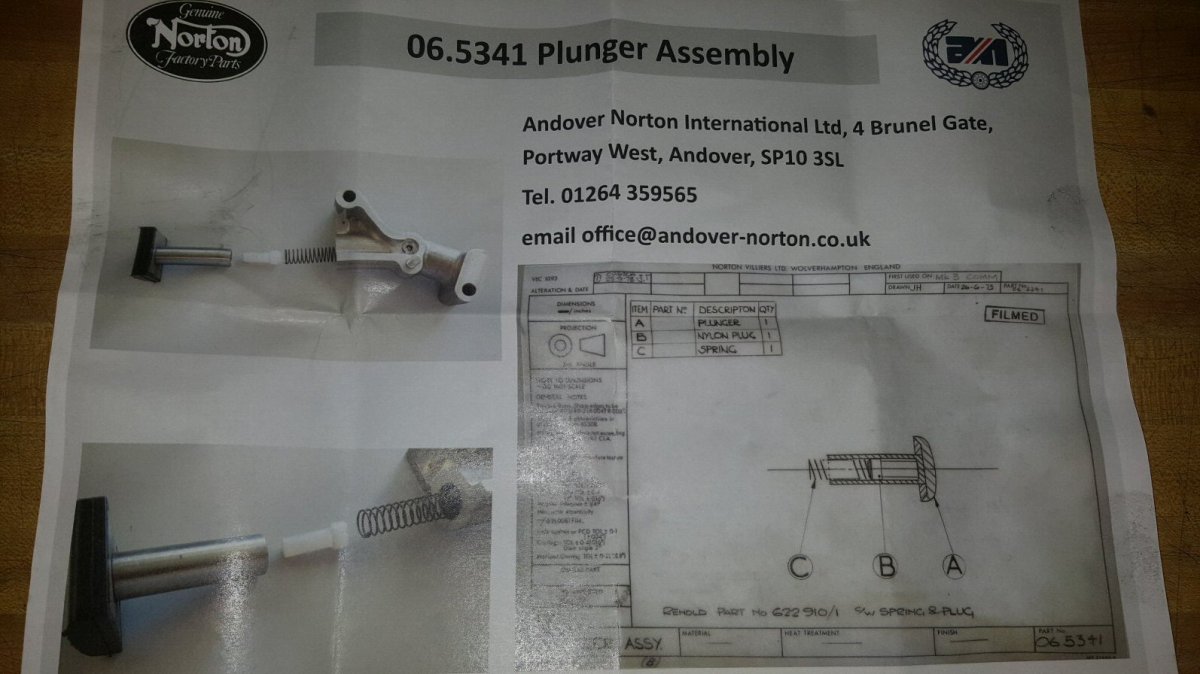

I have been able to source new tensioner plungers and springs, but not the white plastic spring stops. It seems they are only available from A-N with the plunger. As my Mk3 came with just a tensioner body in a box, I do not have the originals to re-use. Does anyone know if these stops are available anywhere on their own?

Andy

not that I am aware of

- Log in to post comments

So which is the right way…

So which is the right way round? Seems to me you put the smaller diameter up inside the spring, i.e. opposite to the colourful diagram. Otherwise, why not have the same diameter over the full length?

Doesn't look like an overly complicated bit of plastic to me. Would acetyl (Delrin) do just as well?

- Log in to post comments

Yes, it’s just a piece of…

Yes, it’s just a piece of Nylon - nothing extravagant or complicated.

- Log in to post comments

It does seem strange that…

It does seem strange that someone designs a 'spacer' that has exactly the right size stub to fit inside the spring and then fits it the other way round.

I agree with Grant that this is what the book says, but why not use a simple bit of plastic the correct length?

Maybe it was designed to go the other way round but found they needed more preload. It is then a documentation change to swap it round rather than a new drawing, new part number and new instructions.

By the way, my tensioner body is machined to take an O ring at the bottom so there are never any leaks, stops the slapping chain noises I used to get when first starting up.

Dangerous to say this I know but I have been using ATF since about 1982 without any issues (yet).

Tony

- Log in to post comments

because...

@tony

To my knowledge, the shape is simply so that you stand a chance of getting it out again to replace it!

As it is, many of them get wedged in, and are a bugger to remove. My guess is there was swarf and burrs at the bottom of the hole when they were made originally.

On the rotary, they used the same assembly (Andover kit is the same part number), however they went to a metal dowel on the top one instead to get the spring pressure right. Confusingly, on the Rotary the same plastic spacer is fitted the other way at the top.

This way because they found the plastic wore away too quick on the top tensioner (where the spring does the damping in the main part without the aid of hydraulic action)

- Log in to post comments

I'm going to have to open…

I'm going to have to open mine up now to see which way I put it together...

I do seem to remember thinking the reduced diameter might have something to do with not obstructing the oil bleed holes in the plunger.

Was the plastic spacer always present? Could they have been metal originally? It's kinda lost in the mists of time, but I don't remember the spacers when I first pulled a Mk3 apart in 1976 - crash damaged write-off. And when I aquired another in 1990 - messed about, lot's of non-original changes - I seem to remember wondering what these white plastic bits were for.

- Log in to post comments

Hmmmm

My first Mk3, an Interpol straight from the police and then only 4 years old, had the stops fitted with the tail inside the spring. They could of course have been previously removed and refitted incorrectly by a police garage. I never experienced any clonking from the primary chain with the stops tail into spring - it was always run with GTX in the primary case, filled to the level plug. I did suffer from a bit of clutch slip for a while, but found that the clutch had the thick pressure plate fitted with sintered plates - not sure why? Fitting the thinner pressure plate on MCS (Leytonstone) advice helped a lot.

Anyway, back to the stops, thank you Grant for your very astute comment about the stops wedging in the plungers. My old plungers came with the bike loose in a box of junk and I assumed the stops were long gone, because on my first Mk3 they just fell out with the springs. However, on closer inspection of those old plungers, I found them stuck inside - what a surprise! One has come out after a bit of tapping, but the other is reluctant to move at the moment. It might just be hydraulic locking because there is oil in there and it seems to rotate, so I will have to find a way to persuade it out.

Andy

- Log in to post comments

Just did some measurements…

Just did some measurements on a plunger (with a stuck nylon stop).

From the open end of the plunger, the bleed hole centre is at 19,3 mm.

The top of the nylon stop, fitted with the reduced diameter towards the open end, is at 21,9 mm.

So I guess the nylon stop cannot obstruct the bleed hole.

- Log in to post comments

The whole assembly has a…

The whole assembly has a Renold part number, all three pieces were supplied by them. No idea why Renold would have the nylon part inserted in the way they are, surely it would have made sense not to use the nylon part all and just use a different length and rate spring. Maybe it was cheaper to use a shorter spring and a nylon plug they were using elsewhere.

- Log in to post comments

Any Saab buffs out there? …

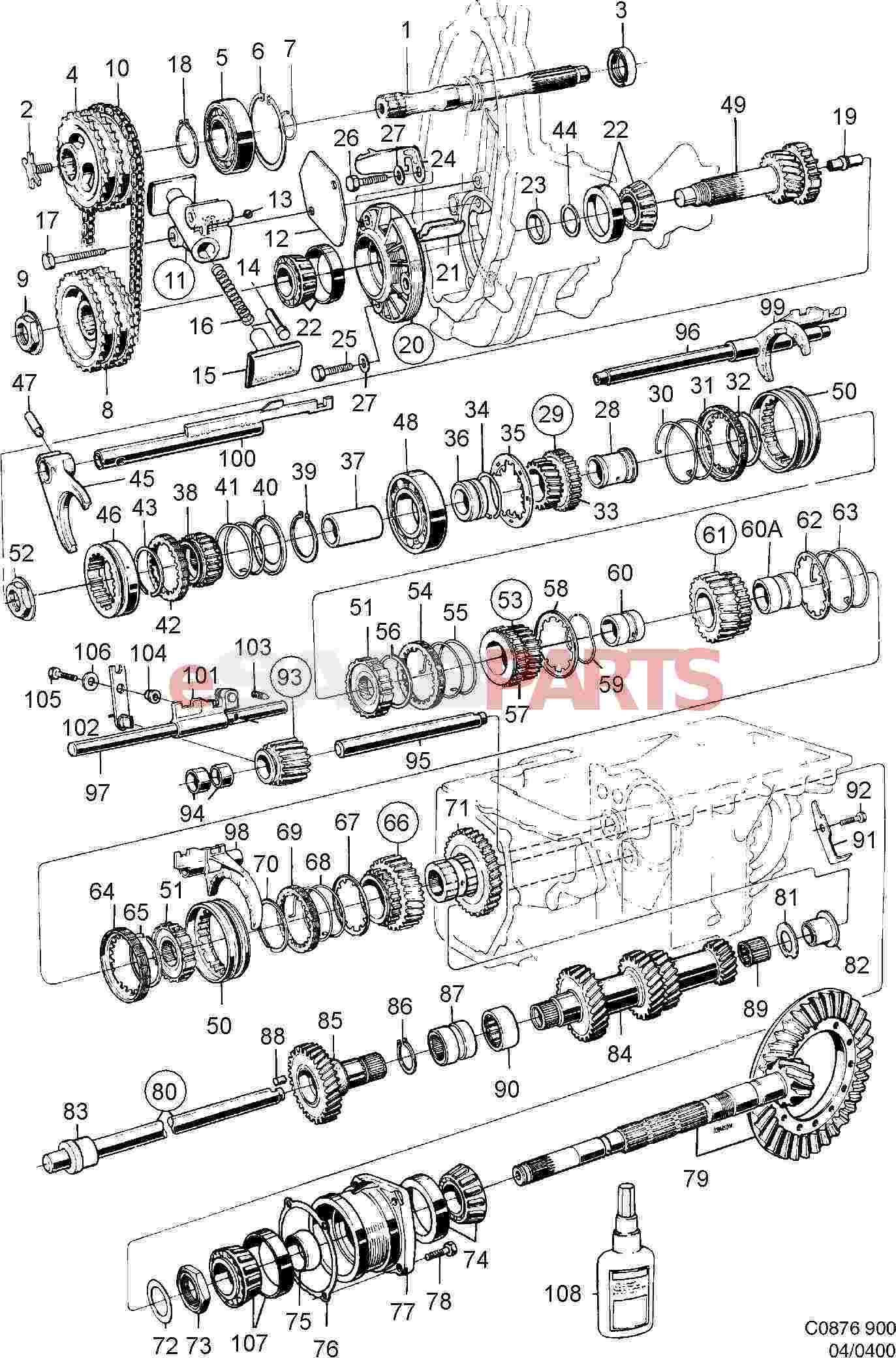

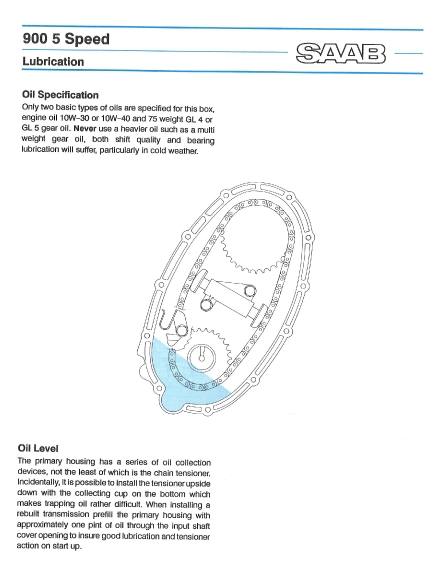

Any Saab buffs out there?

Early eighties, a paper was prepared on joint efforts by Renold and Saab Scania in developing a transfer drive system with a chain between motor and gearbox.

Some Saab models actually have this system fitted which incorporates a double acting hydraulic chain tensioner sort of similar to the one in the Mk3.

The paper has a picture of the tensioner, it has the same British patent nr. 861741 number on it as the Mk3 plungers have.

According to the paper, there is only one stop, with the thin end going in first.

On later 900 models, another version of the tensioner, with coaxial plungers, and also one stop.

According to the parts drawing, here the thick end goes in first.

The drive ratio on these models can be altered by changing gears, resulting in more or less "play" of the chain.

Whether that has someting to do with the nylon stop..? Who knows?

- Log in to post comments

Plunger Nylon Stops Available Separately

I know it's a slightly older topic, but for the record, if you ring AN, they supply the nylon parts separately.

I found my Mk 3 had a hex screw inside the bottom plunger, rather than a nylon stop. It was about 2mm longer than the nylon version. I think this applied more tension and ultimately caused the top plunger to seize in. In turn, this put all the pressure downwards on the triplex chain. Sadly, the chain started to wear and cut nice grooves in the bottom of the alloy inner case, filling it with a nice metallic sludge.

I think this was the cause of my sprag failing!

- Log in to post comments

I have never seen these for sale separately.

Perhaps it’s worth giving Andover a call and requesting that they list the nylon spacers as separate items.

If you do find some, or you choose to buy the Andover kit, make sure you assemble them correctly.

There is a lot of misinformation out there about this subject.

The correct way to fit (as per Norton’s original design) is as per my drawing below. This is how every MK3 went out. Unfortunately, when owners dismantle and rebuild them, it is assumed they were assembled wrongly. When the plastic spacer is put in the wrong way, the chain is not tensioned enough and will slap (and damage) the primary case.

Also, make sure you run 20/50 engine oil in your primary, and not the ATF that we all recommend for pre-MKs

Thicker oil is important for the tensioner to work properly, but more so for the sprag to give you decent service life.

Prime the tensioners before you put your primary cover on.

Measure your 200ml rather relying on the level plug.